Method and system for automatic calibration of pressure difference zero point value of wind speed measurement

A technology for wind speed measurement and automatic calibration, which is applied in the testing/calibration of speed/acceleration/shock measuring equipment, speed/acceleration/shock measurement, and measuring devices, etc. The lower limit accuracy of the wind speed measuring instrument has a great influence, so as to achieve the effect of ensuring accuracy and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

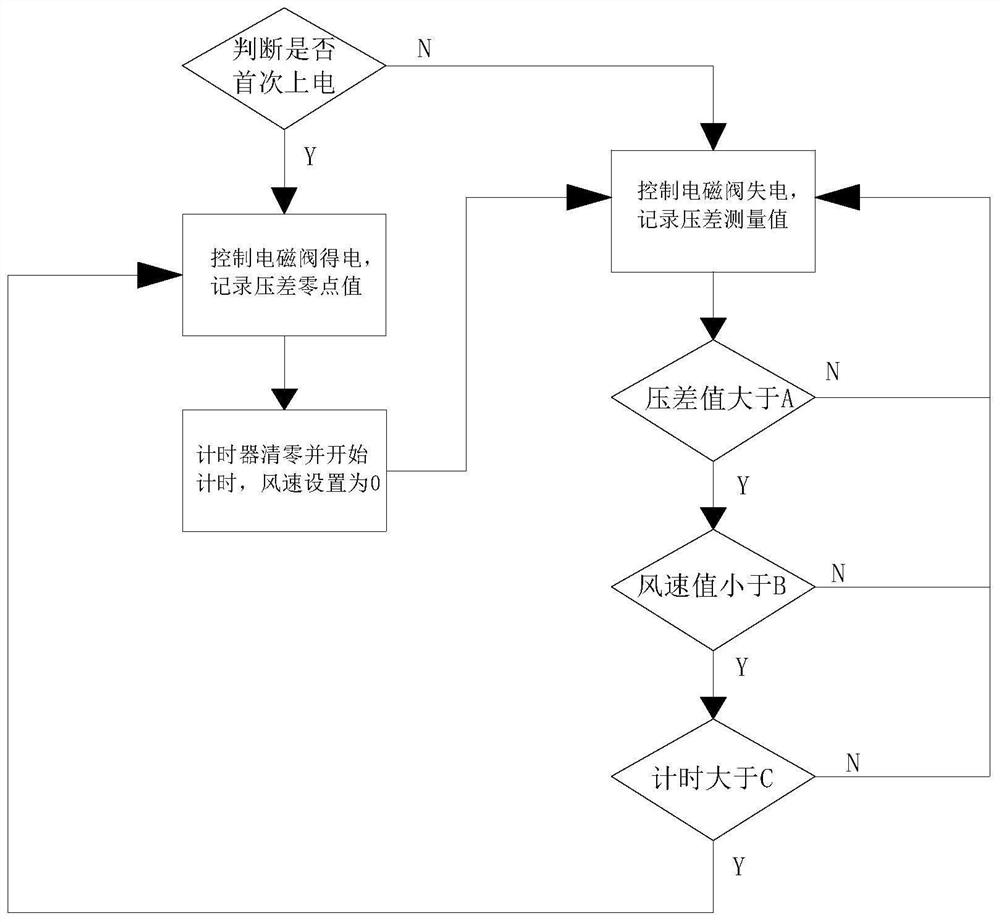

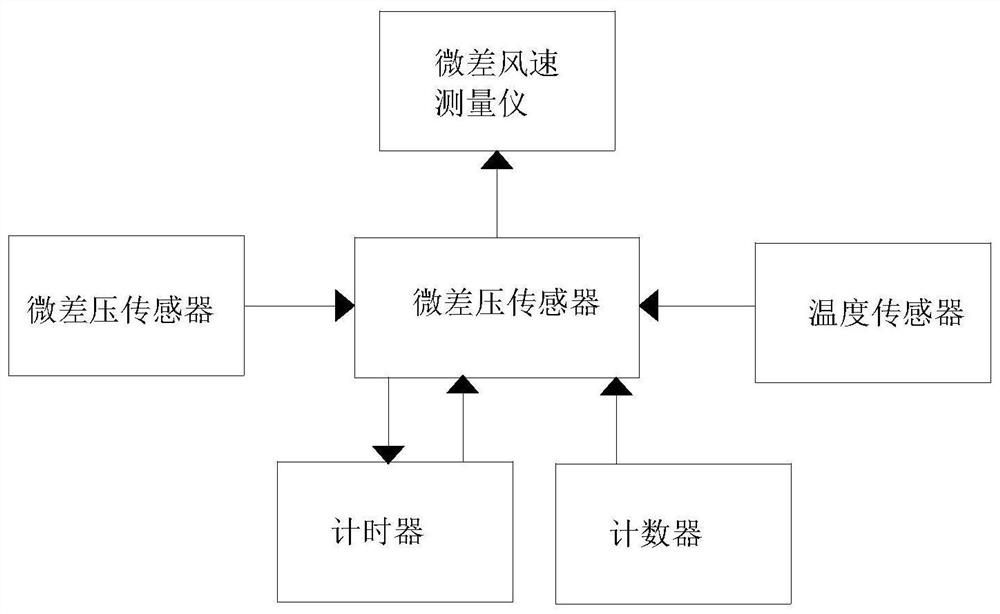

[0027] figure 1 Be the flow chart of the present invention, figure 2 It is a schematic block diagram of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings. The present invention provides a method for automatic calibration of the pressure difference zero point value of wind speed measurement, which is characterized in that: comprising:

[0028] S1: Determine whether the differential pressure anemometer is powered on for the first time, if so, go to step S2, if not, go to step S4;

[0029] S2: Control the solenoid valve to be energized, record the value of the differential pressure sensor when the positive pressure port and negative pressure port of the differential pressure anemometer are connected, and the value of the differential pressure sensor when the positive pressure port and negative pressure port are connected is pressure difference zero point value;

[0030] S3: clear the timer of the diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com