Multi-polarization-state generator based on meta-structure surface

A metasurface, multi-polarization technology, applied in the direction of polarizing elements, can solve the problems that cannot be realized, and the miniaturization of devices cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

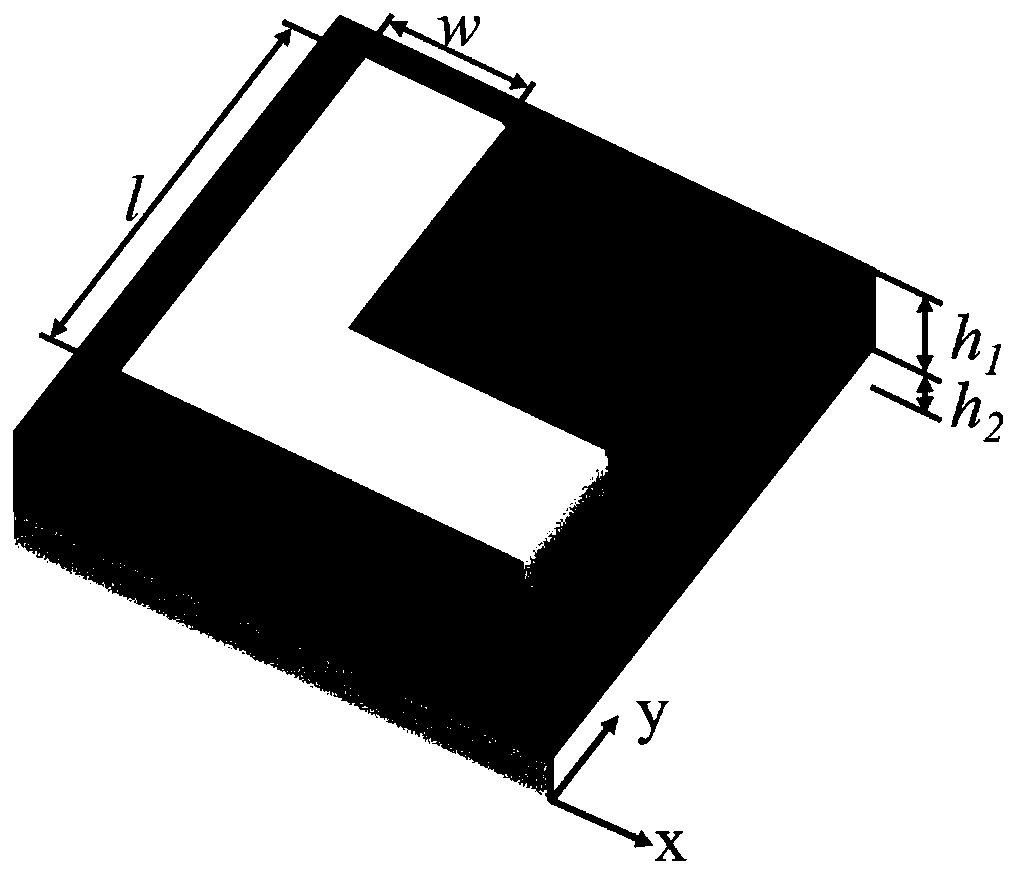

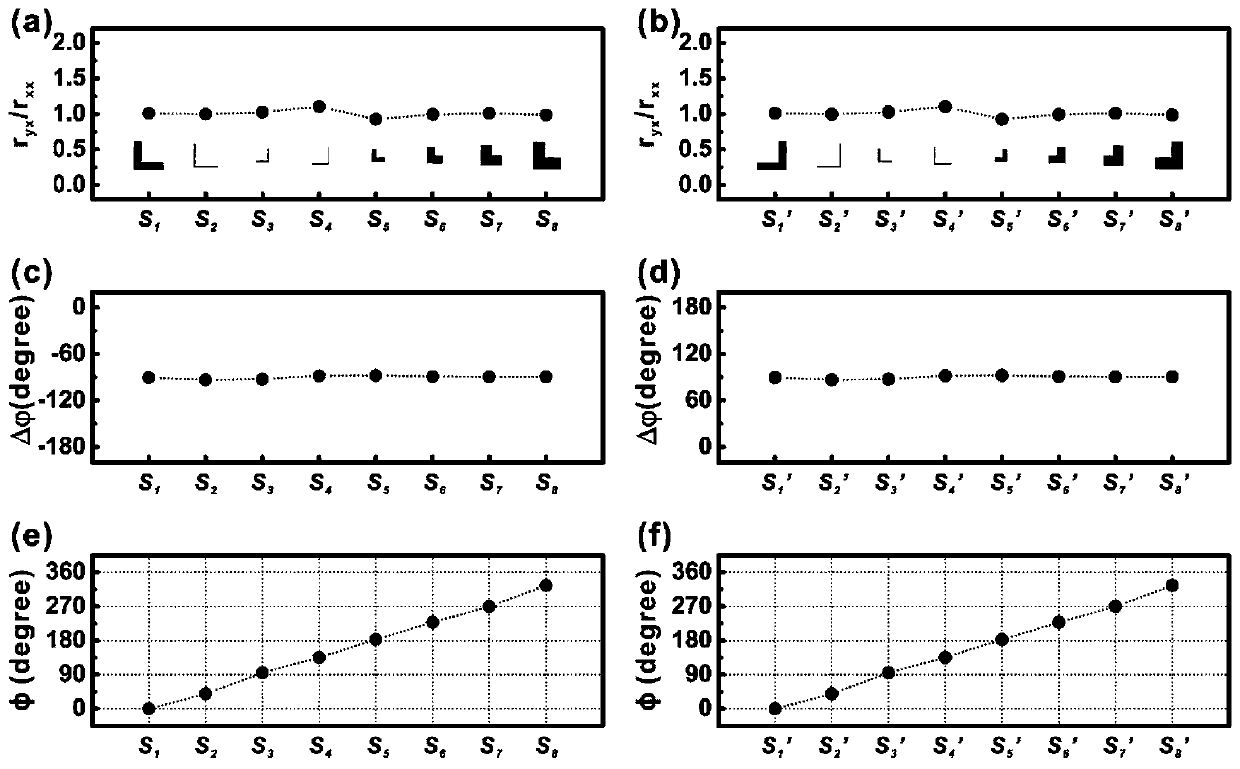

Method used

Image

Examples

Embodiment 1

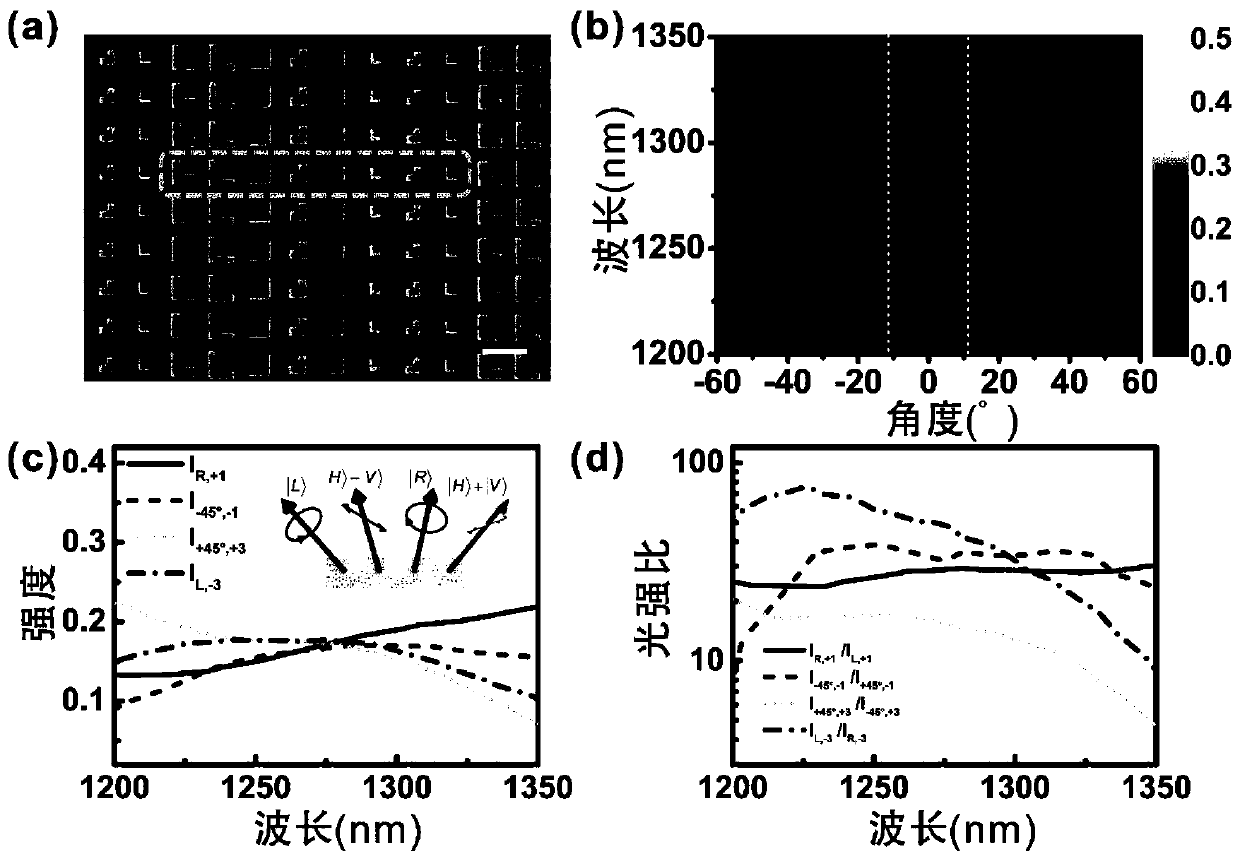

[0063] Embodiment 1: In this embodiment, the specific response band 1250-1300nm of the microstructure is located in the near-infrared band, image 3 It is the experimental diagram of the beam splitting of the multi-polarization generator in the first arrangement. image 3 (a) is the scanning electron micrograph of the prepared sample. There are 8 microstructures in the structural unit of the polarization generator, corresponding to S 8 ,S 1 ,S 2 ’,S 7 ’,S 4 ,S 5 ,S 6 ’,S 3 '. image 3 In (b) is the wide-angle diffraction spectrum in the wavelength range of 1200nm to 1350nm, the angle measurement range is (-60°)-(-12°) and 12°-60° (the area on both sides of the white dotted line), in the figure The color reflects the strength of reflectivity (reflected light intensity / incident light intensity). The spatial distribution of the diffracted light shows that in the 1250-1300nm band, four beams of diffracted light along the +3, +1, -1, -3 orders are generated simultaneously,...

Embodiment 2

[0064] Example 2: Figure 4It is the experimental diagram of the beam splitting of the multi-polarization generator in the second arrangement mode, and the specific response band is 1250-1300nm. Figure 4 (a) is the scanning electron micrograph of the prepared sample. There are 8 microstructures in a polarizing beam splitter structural unit, corresponding to S 1 ,S 8 ’,S 1 ,S 8 ’,S 5 ,S 4 ’,S 5 ,S 4 '. Figure 4 In (b) is the wide-angle diffraction spectrum in the wavelength range of 1200nm to 1350nm, the angle measurement range is (-60°)-(-12°) and 12°-60° (the area on both sides of the white dotted line), the diffracted light The spatial distribution shows that at 1250-1300nm, four beams of diffracted light along the +3, +1, -1, -3 orders are produced simultaneously, while the even orders are extinguished. Figure 4 Middle (c) is the experimental measurement result of the reflected light intensity of the four beams. I +45°,+1 Indicates the reflectivity of +1 order...

Embodiment 3

[0065] Example 3: Figure 5 It is the experiment and simulation diagram of multi-polarization generator beam splitting under the third arrangement mode, and the specific response band is 1250-1300nm. Figure 5 (a) is the scanning electron micrograph of the prepared sample. There are 8 microstructures in a polarizing beam splitter structural unit, corresponding to S 1 ,S 2 ,S 5 ’,S 2 ’,S 5 ,S 6 ,S 1 ’,S 6 '. Figure 5 In (b) is the wide-angle diffraction spectrum in the wavelength range of 1200nm to 1350nm, the angle measurement range is (-60°)-(-12°) and 12°-60° (the area on both sides of the white dotted line), the diffracted light The spatial distribution shows that at 1250-1300nm, four beams of diffracted light along the +3, +1, -1, -3 orders are produced simultaneously, while the even orders are extinguished. Figure 5 In (c) is the experimental measurement result of the intensity of the four beams of reflected light, I R,+1 Indicates the reflectivity of +1 order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com