Preliminary screening equipment for tea picking

An equipment and tea technology, applied in the field of tea picking and primary screening equipment, can solve the problems of slow picking speed, time-consuming and labor-intensive, etc., and achieve the effect of fast picking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

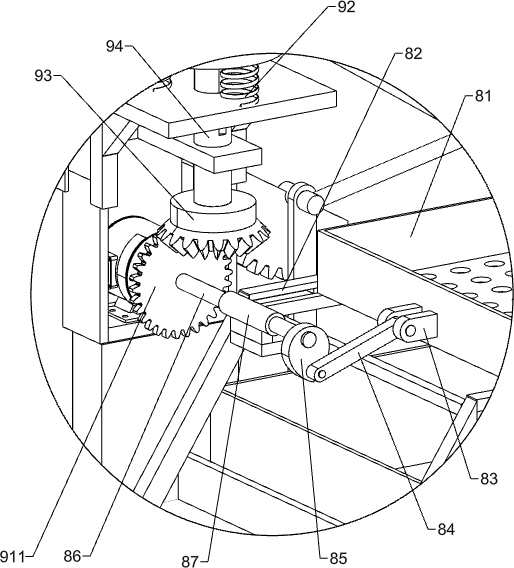

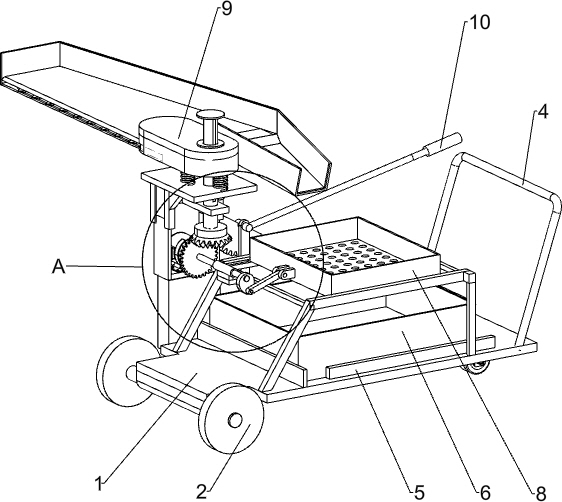

[0021] A tea picking primary screening equipment, such as Figure 1-4 As shown, it includes car board 1, roller 2, universal wheel 3, push rod 4, limit block 5, tea box 6, servo motor 7, screening mechanism 8 and picking mechanism 9, and the bottom front side of car board 1 rotates There are two rollers 2 connected in the same way, and the two rollers 2 are left and right symmetrical. The universal wheel 3 is installed on the bottom and rear side of the vehicle plate 1, and the push rod 4 is connected to the top and rear side of the vehicle plate 1. The vehicle plate on the front side of the push rod 4 1. The tea box 6 is slidably connected to the top, and the top of the car plate 1 outside the tea box 6 is connected to the limit block 5. The top of the car plate 1 outside the limit block 5 is equipped with a screening mechanism 8, and the left side of the car plate 1 is fixed on the front side. Connect the mounting seat, the inner top of the mounting seat is equipped with a s...

Embodiment 2

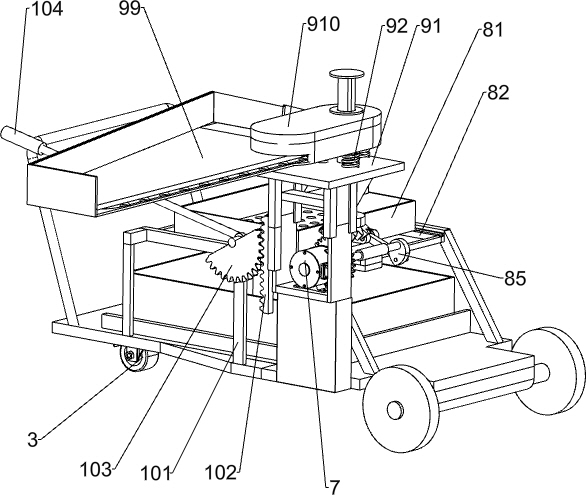

[0026] On the basis of Example 1, such as figure 1 and figure 2 As shown, a height adjustment mechanism 10 is also included. The height adjustment mechanism 10 includes a shaft rod 101, a rack 102, a half-toothed long rod 103 and a handle 104. The top of the vehicle plate 1 on the rear side of the mounting seat is connected with a shaft rod 101 The top of shaft bar 101 is rotatably connected with half-toothed long rod 103, and the right part of the power transmission shaft of half-toothed long rod 103 is connected with handle 104, and the rear side bottom of movable base 91 is connected with rack 102, and rack 102 and half-toothed Long rod 103 engages.

[0027] The picker can press the grip 104 downwards to make the half-tooth long rod 103 rotate clockwise, and the clockwise rotation of the half-tooth long rod 103 can make the rack 102 move upwards, and the upward movement of the rack 102 drives the movable base 91 to move upward, and the movable base 91 Moving upwards can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com