Wood spoon burr removing device

A technology of burrs and wooden spoons, which is applied to grinding drive devices, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve problems such as labor consumption, hand injury, safety accidents, etc. Manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

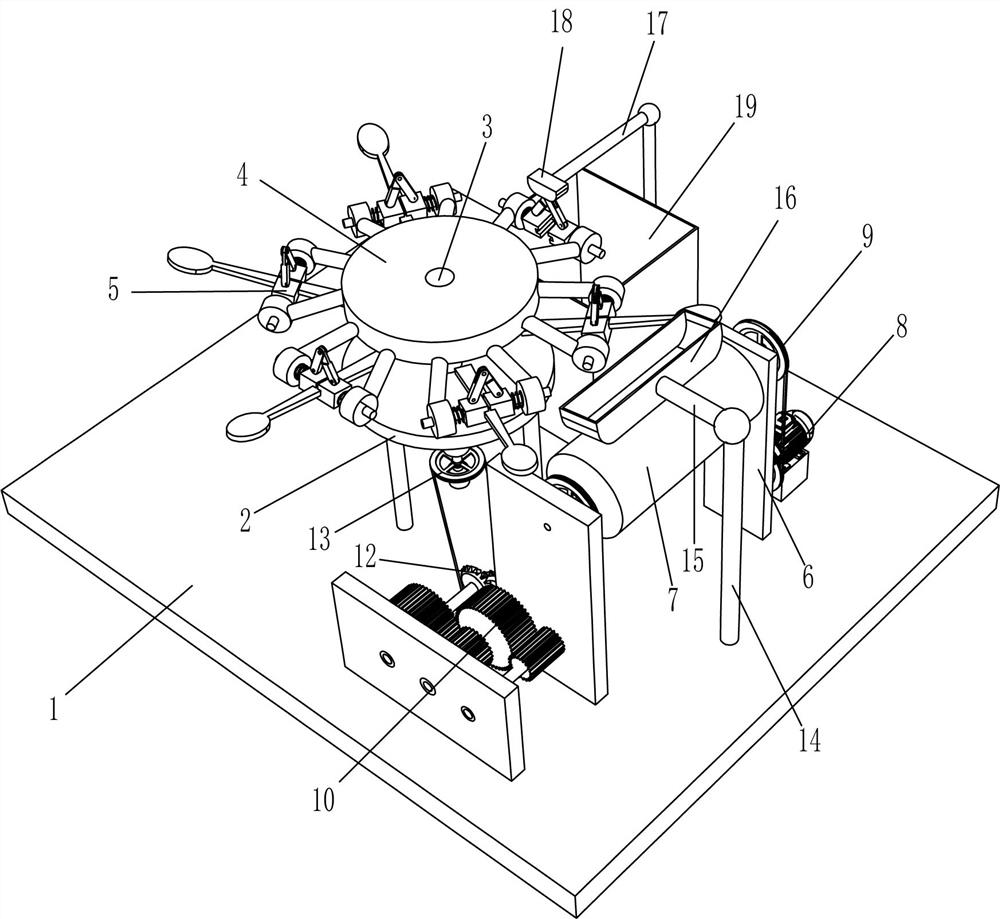

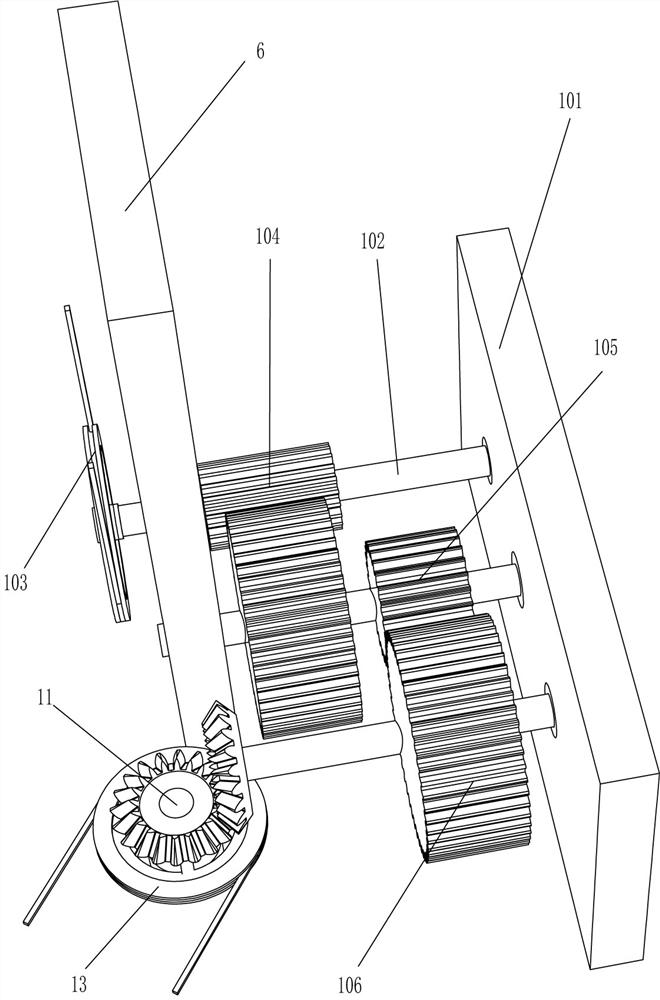

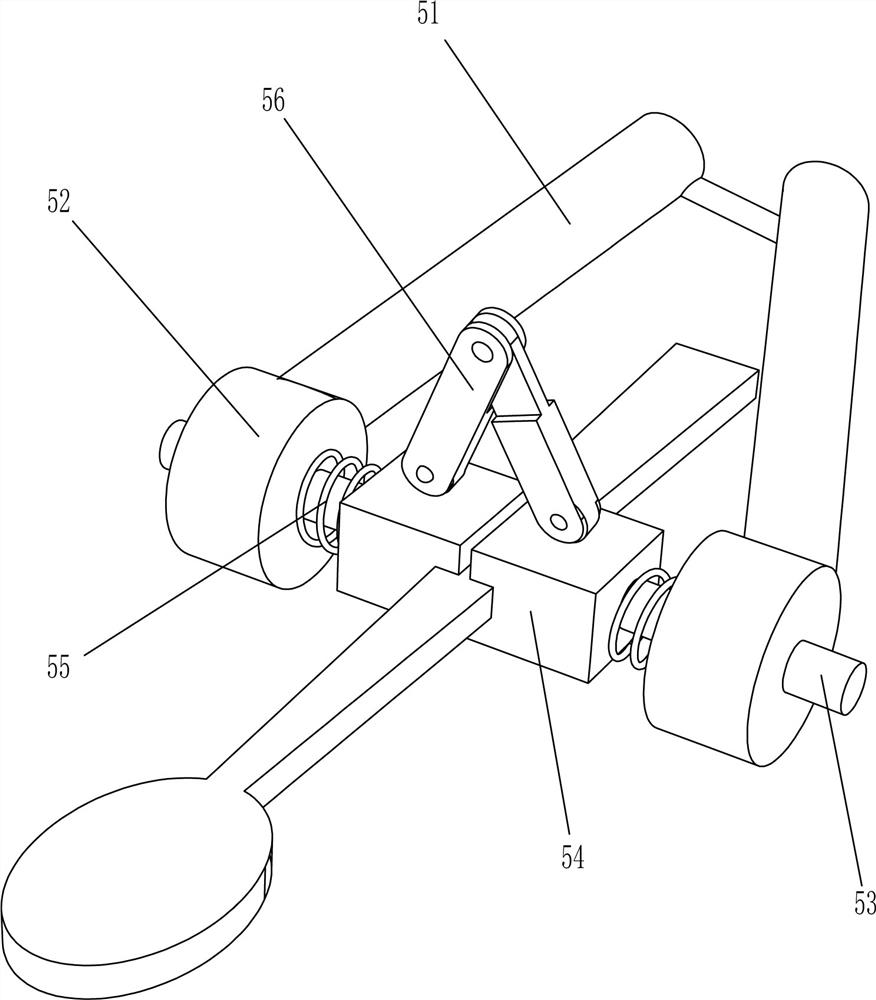

[0023] A wooden spoon burr removal device, such as Figure 1-3 As shown, it includes a base 1, a workbench 2, a first rotating shaft 3 and a disk 4, the middle of the top of the base 1 is connected with a workbench 2, the workbench 2 is rotatably connected with a first rotating shaft 3, and the top of the first rotating shaft 3 is connected to There is a disc 4, and also includes a clamping mechanism 5, a bearing seat 6, a grinding wheel 7, a servo motor 8, a first belt transmission mechanism 9, a reduction mechanism 10, a rotating shaft 11, a bevel gear 12 and a third belt transmission mechanism 13 , the disk 4 is provided with a clamping mechanism 5, the top right side of the base 1 is connected with a bearing seat 6, the bearing seat 6 is connected with a grinding wheel 7 in a rotating manner, and the top of the base 1 at the rear side of the bearing seat 6 is connected with a servo motor 8, A first belt transmission mechanism 9 is connected between the output shaft of the ...

Embodiment 2

[0028] On the basis of Example 1, such as figure 1 As shown, it also includes a mounting rod 14, a connecting rod 15 and a wedge-shaped top block 16, the right side of the top of the workbench 2 is connected with the mounting rod 14, the top of the mounting plate 101 is connected with a connecting rod 15, and the connecting rod 15 is connected with a wedge-shaped top block 16. The wedge-shaped top block 16 is located above the grinding wheel 7, and the wedge-shaped top block 16 will be in contact with the wooden spoon.

[0029] Wooden spoon can contact with wedge-shaped top block 16 when rotating, after wooden spoon rotates to contact with wedge-shaped top block 16, wooden spoon continues to rotate and moves downward through the slope of wedge-shaped top block 16, when wooden spoon moves down to limit, The wooden spoon just moves to be in contact with the grinding wheel 7, so that the wooden spoon does not need to be manually pulled to move downward, which effectively saves ma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap