A clamping tool for fitter processing

A technology of clamping tooling and fitter processing, applied in the field of fitter equipment, can solve the problems of small number of stress points, narrow distribution area, uneven effect of inner support force on the inner wall of pipe fittings, etc., and achieve a wide range of use and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

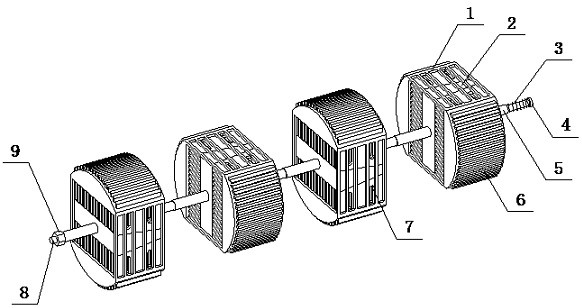

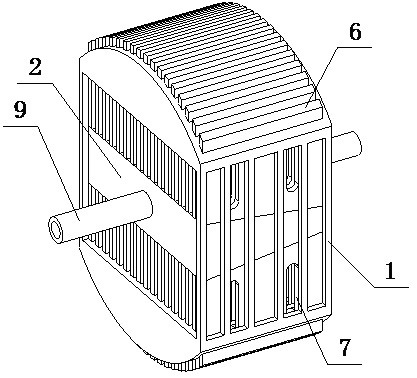

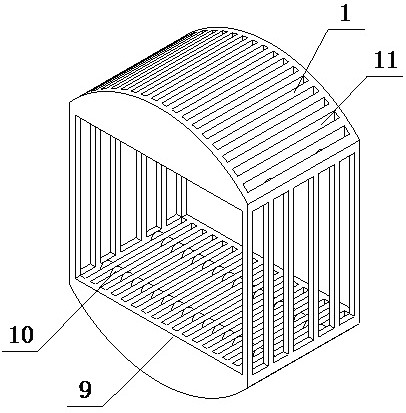

[0018] A clamping tool for fitter processing of the present invention is realized in the following way: a clamping tool for fitter processing of the present invention is composed of a support structure and a connection structure, and the support structure is composed of a fixed frame (1), a wedge-shaped top block ( 2), guide sleeve (5), support rib plate (6), chute (7), sliding column (10) and guide groove (11), the fixed frame (1) is a rectangular frame structure, the Both ends of the fixed frame (1) are arched to form an arc-shaped block, and a set of guide grooves (11) are respectively opened at both ends of the fixed frame (1), and at least two sliding posts (10) are placed in a set of guide grooves ( 11), the two ends of the sliding column (10) are respectively fixedly connected with the two sides of the fixed frame (1), and the two ends of the fixed frame (1) are respectively provided with avoidance grooves, and the wedge-shaped top block (2) Placed in the fixed frame (1...

Embodiment 2

[0021] The difference between this embodiment and Embodiment 1 is: the wedge-shaped top block (2) is replaced by a rectangular block (13), and one end of a plurality of spreading plates (12) is placed equidistantly on the rectangular block (13), and close to On one side of the rectangular block (13), the other side of the spreading plate (12) extends obliquely upwards towards the other side of the rectangular block (13); ) can be deformed and buffered when braced to avoid excessive force applied to the supporting ribs (6) during internal braces, resulting in internal deformation of the pipe fittings;

[0022] The design of the spring (3) enables the device to be taken out of the pipe after the processing of the pipe is completed, the lock cap (9) is turned back, and the guide sleeve (5) is reset under the reset action of the spring (3) for subsequent use ;

[0023] The two ends of the fixing frame (1) are respectively provided with the design of avoiding grooves, which reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com