Glass drying equipment and glass drying method for touch screen processing

A technology of drying equipment and touch screen, which is applied in glass manufacturing equipment, glass transportation equipment, lighting and heating equipment, etc. It can solve the problems of easy scratched glass, easy scratched silk screen pattern, glass easy to slip, etc. It is not easy to achieve Slipping, safe handling, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

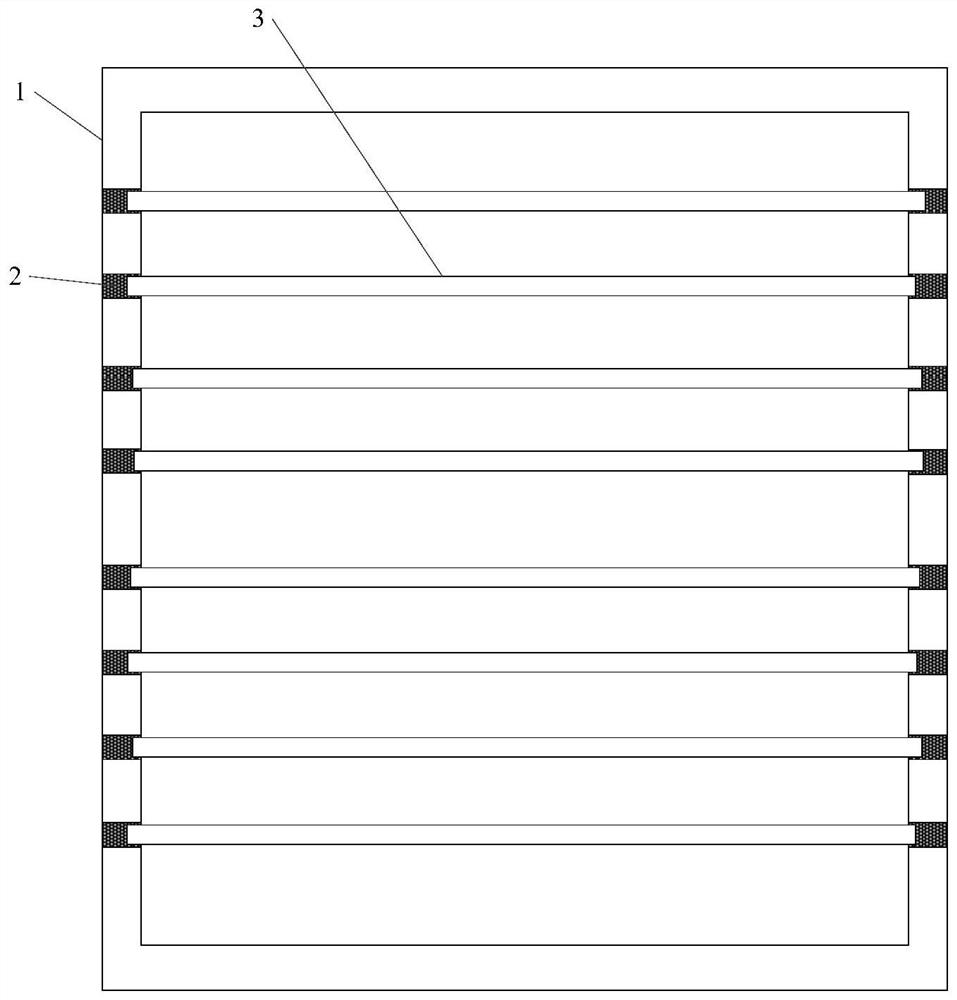

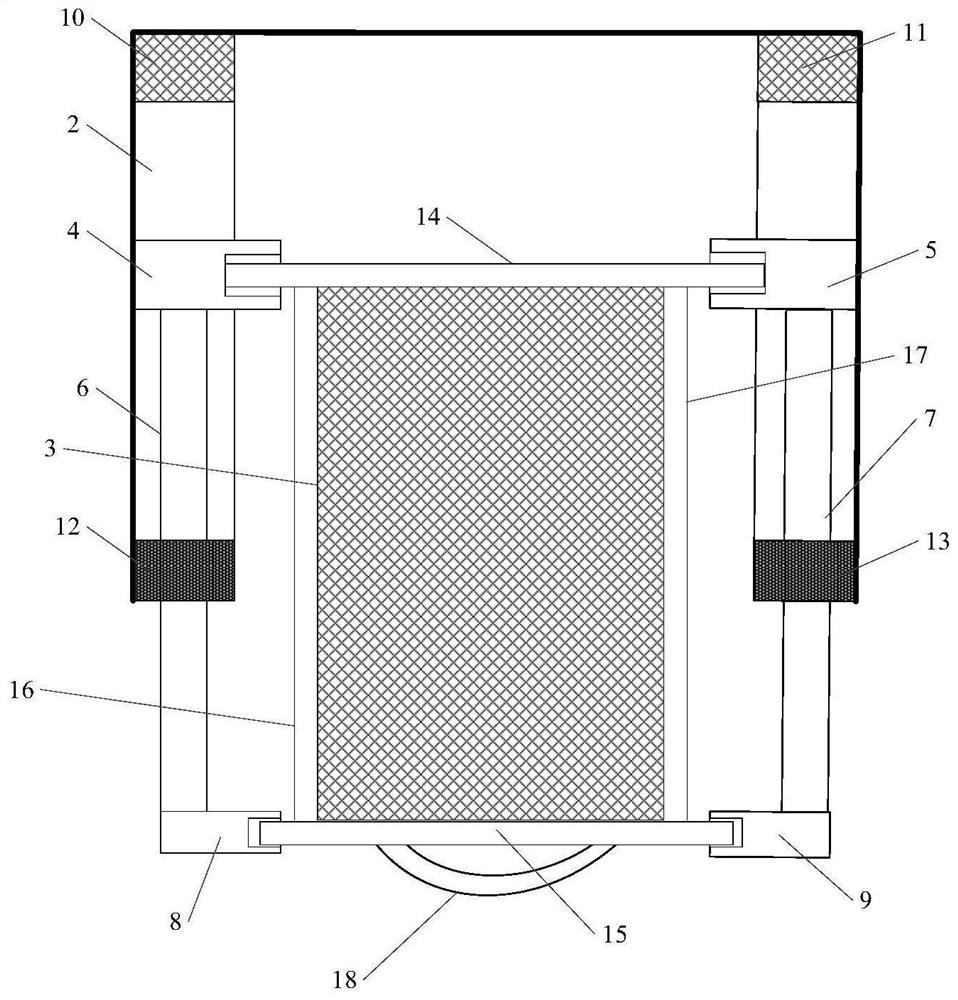

[0065] Please refer to Figure 3-Figure 4 , this embodiment provides a glass drying equipment for touch screen processing, the equipment includes a baking oven, the left and right inner walls of the oven are correspondingly provided with several pairs of chutes 2, and each pair of chutes corresponds to a glass drying oven. layer, the device also includes: several glass fixing structures, several first sliders 4, several second sliders 5, several first telescopic rods 6, several second telescopic rods 7, several first fixed blocks 8, several first telescopic rods Two fixed blocks 9, some first buffer blocks 10, some second buffer blocks 11, some first stop blocks 12 and some second stop blocks 13, each glass baking layer corresponds to a glass fixing structure, and the glass Fixed structures include:

[0066] The first fixed rod 14, the second fixed rod 15, the first fastening belt 16, the second fastening belt 17 and the handle 18; the first fixed rod and the second fixed rod...

Embodiment 2

[0074] Please refer to Figure 5-Figure 6 , on the basis of Embodiment 1, the device in Embodiment 2 also includes:

[0075] Stepping motor 25, stepping motor controller, several racks 20, several cross bars 21, some first driving rods 22 and some second driving rods 23;

[0076] Each glass baking layer corresponds to a rack, each rack corresponds to a cross bar, each cross bar corresponds to a first drive rod and a second drive rod, one end of the rack is fixedly connected to the middle of the corresponding cross bar, The two ends of the cross bar are respectively connected to one end of the corresponding first driving rod and one end of the second driving rod, and the other end of the first driving rod passes through the rear wall of the oven and the corresponding first buffer block in sequence and connects with the corresponding first driving rod. A slide block is fixedly connected, and the other end of the second driving rod passes through the rear wall of the oven and th...

Embodiment 3

[0079] Please refer to Figure 7 , on the basis of Embodiment 1, the device in Embodiment 3 also includes:

[0080] Glass unloading structure, the glass unloading structure includes a number of pulleys 26 evenly arranged horizontally, the horizontal centerlines of several pulleys coincide with the horizontal centerline of the glass conveyor belt 27, and the distance between the pulley closest to the glass conveyor belt and the glass conveyor belt The distance is less than one-fifth of the width of the glass, the distance between two adjacent pulleys is less than half of the width of the glass, and the gap between two adjacent pulleys corresponds to a glass fixing structure.

[0081] Wherein, the surface of the pulley is provided with a protective pad. The protective pad is a rubber pad or a sponge pad. The pulley is connected with the second rotating shaft, and the second rotating shaft can be installed and fixed through the bracket.

[0082] Please refer to Figure 15-Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com