Loading, unloading and transporting platform for loading and unloading of air-drop cargo platform

A technology of transportation platform and cargo platform, which is applied in the direction of equipment used for transportation, transportation and packaging, ground installations, etc., and can solve the problems of mismatching positions, inability to perform loading and unloading functions, lack of lateral limit and longitudinal guide devices, etc. It achieves the effect of light weight, meeting the requirements of road, rail and air transportation, and fast assembly and withdrawal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

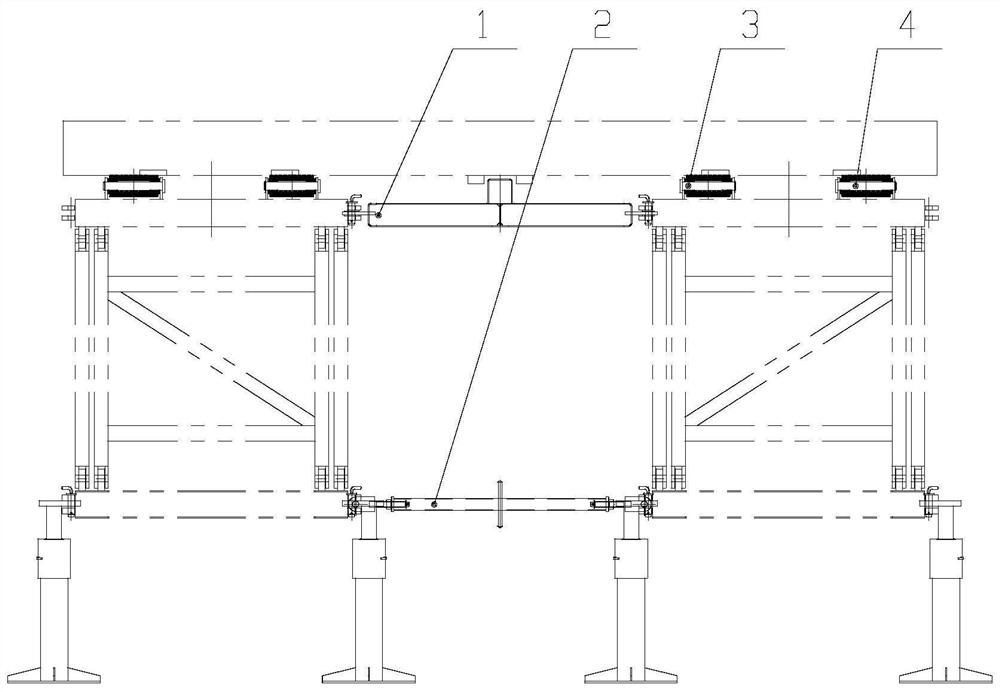

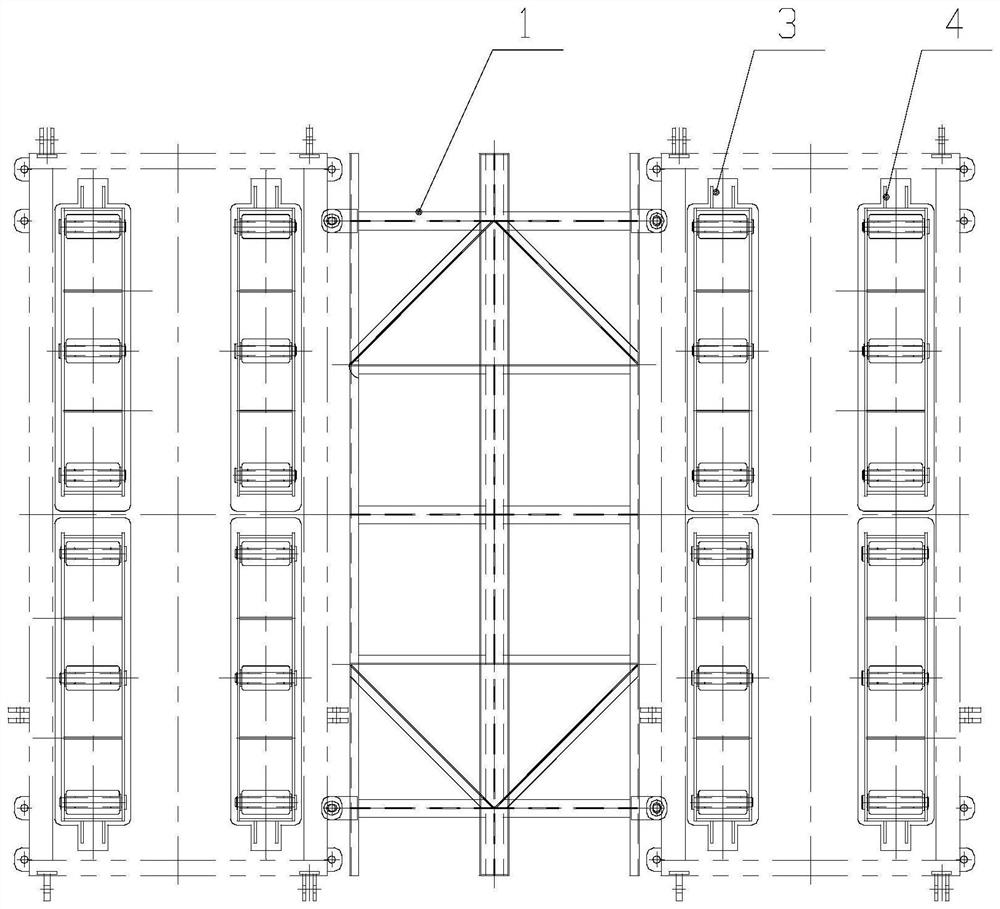

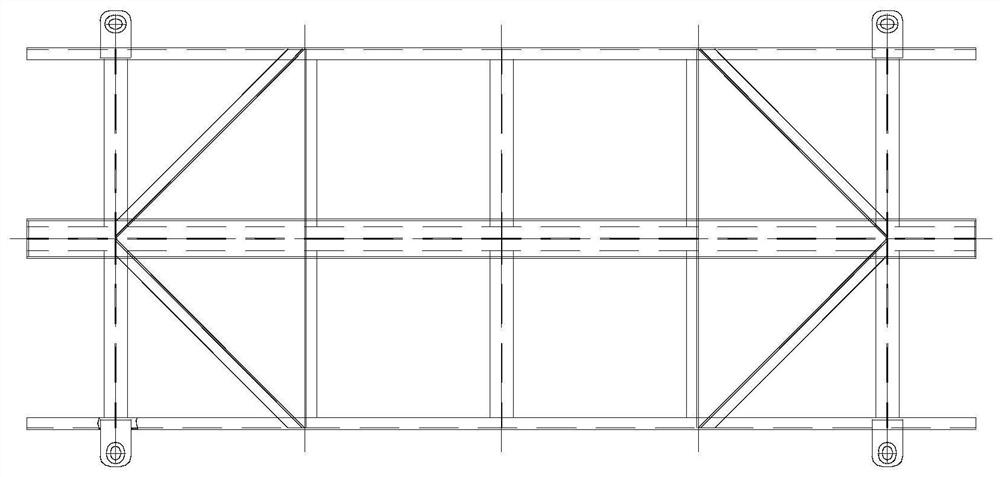

[0036] This embodiment provides a loading and unloading transport platform for loading and unloading of air-drop cargo platforms, see the attached Figure 1-2 , including: cargo platform limit frame 1, transverse connecting rod 2, first slide rail 3, second slide rail 4 and auxiliary cargo bridge 5;

[0037] See attached Figure 3-4 , the cargo platform spacer frame 1 is a planar frame structure composed of folded plates, the length direction of the planar frame structure is longitudinal, and the width direction is transverse; the planar frame structure is provided with a A symmetrical guide beam, which is also composed of flanged plates; four lug plates along the transverse direction are respectively processed on the four corners of the plane frame structure, and each lug plate is processed with a round hole; The flanged boards are long boards with a U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com