Synchronous calibration device and calibration method for trigger signal sending direction

A technology for sending direction and triggering signals, applied in measurement devices, electronic circuit testing, instruments, etc., can solve the problems of AC calibration board digital board difficulty and other problems, and achieve the effect of reducing the difficulty of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

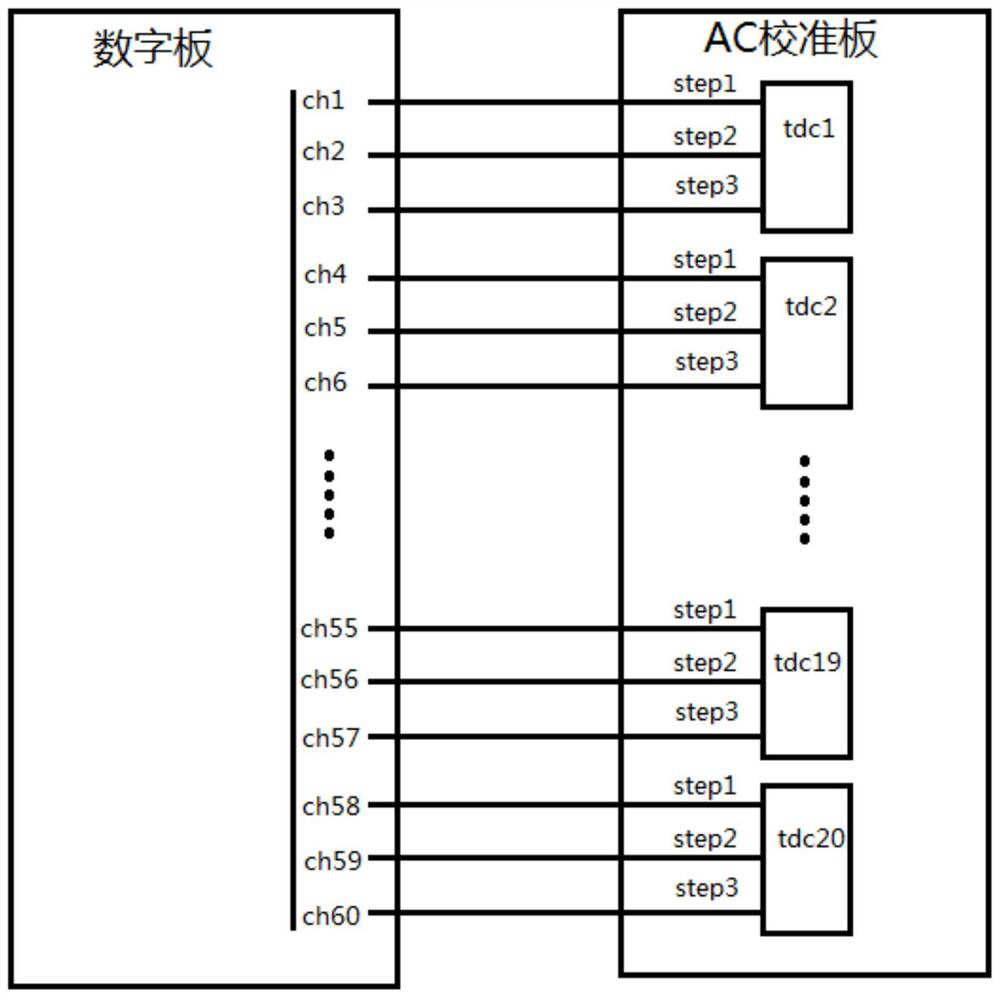

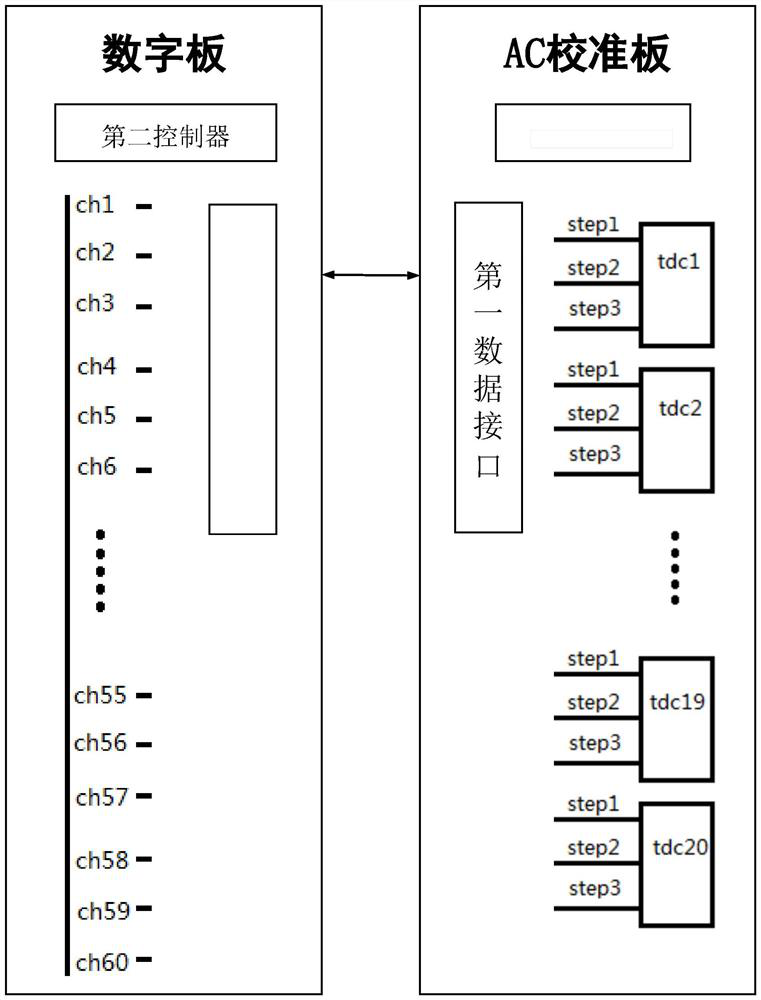

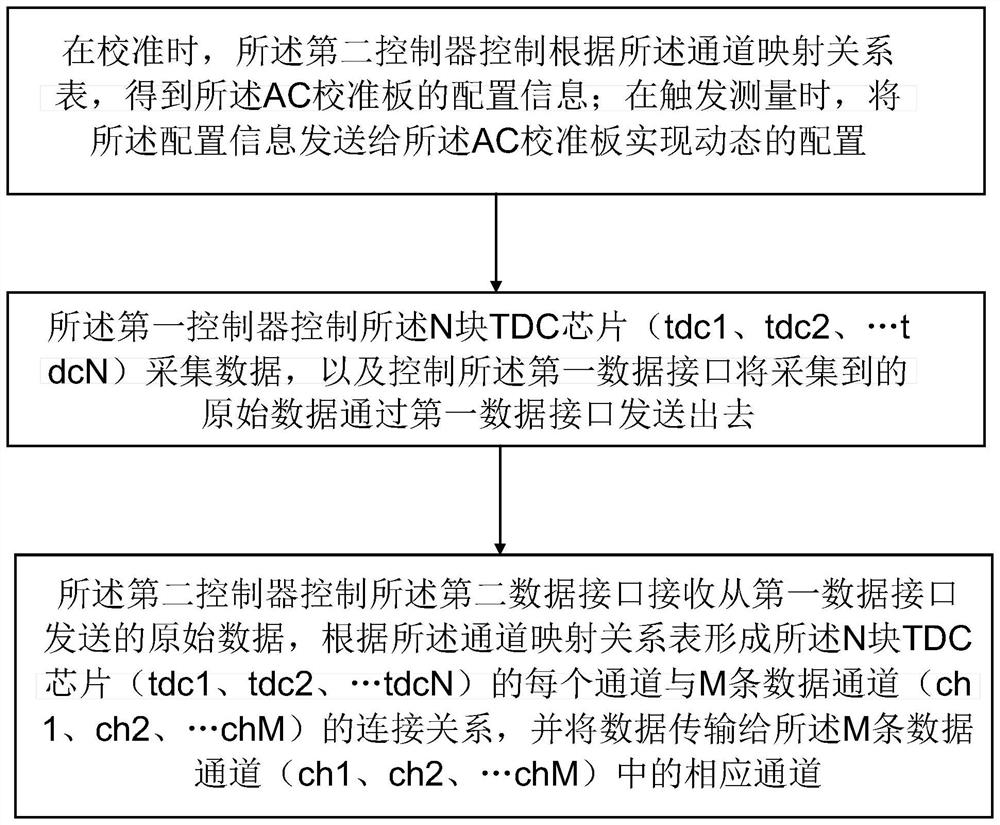

[0030] see figure 2 , figure 2 Shown is a schematic diagram of the connection relationship between each channel of the AC calibration board and the channel of the digital board in the embodiment of the present invention. Such as figure 2 As shown, the synchronous calibration device in the sending direction of the trigger signal includes a digital board module and an AC calibration board module; the AC calibration board includes 20 TDC chips (tdc1, tdc2, ... tdc20), and the digital board includes 60 data channels (ch1, ch2, ... ch60), the connection relationship between each channel of each TDC chip and the channel of the digital board is mainly shown as the mapping relationship between the above channels. Moreover, each TDC chip has three measurement channels (step1, step2 and step3), therefore, 20 TDC chips also have 60 channels.

[0031] In the embodiment of the present invention, the digital board saves the mapping relationship table of its own 60 data channels (ch1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com