Constant-pressure liquid automatic pouring machine

A filling machine and liquid technology, applied in liquid bottling, liquid filling, liquid treatment, etc., can solve problems such as liquid qualitative change, and achieve the effect of occlusal fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

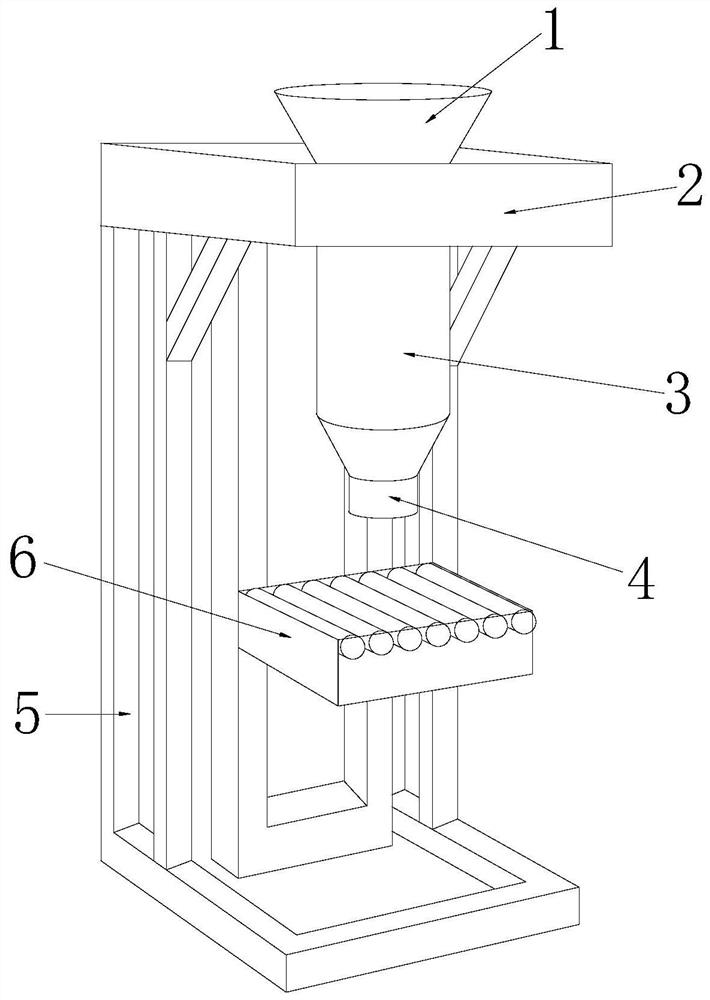

[0026] see Figure 1-Figure 6 , the present invention provides an automatic filling machine for normal-pressure liquids, the structure of which includes a hopper 1, an upper plate 2, a liquid storage chamber 3, an adapter 4, a fixing frame 5, and a workbench 6, and the hopper 1 is arranged on the upper layer On the top of the plate 2, the feeding bucket 1 communicates with the liquid storage cavity 3 through the upper plate 2, the liquid storage cavity 3 is installed in the south direction of the upper plate 2, the fixed frame 5 is mechanically welded with the workbench 6, and the fixed The frame 5 is fixedly connected with the upper plate 2, the workbench 6 is installed in the south direction of the connector 4, and the connector 4 communicates with the liquid storage chamber 3;

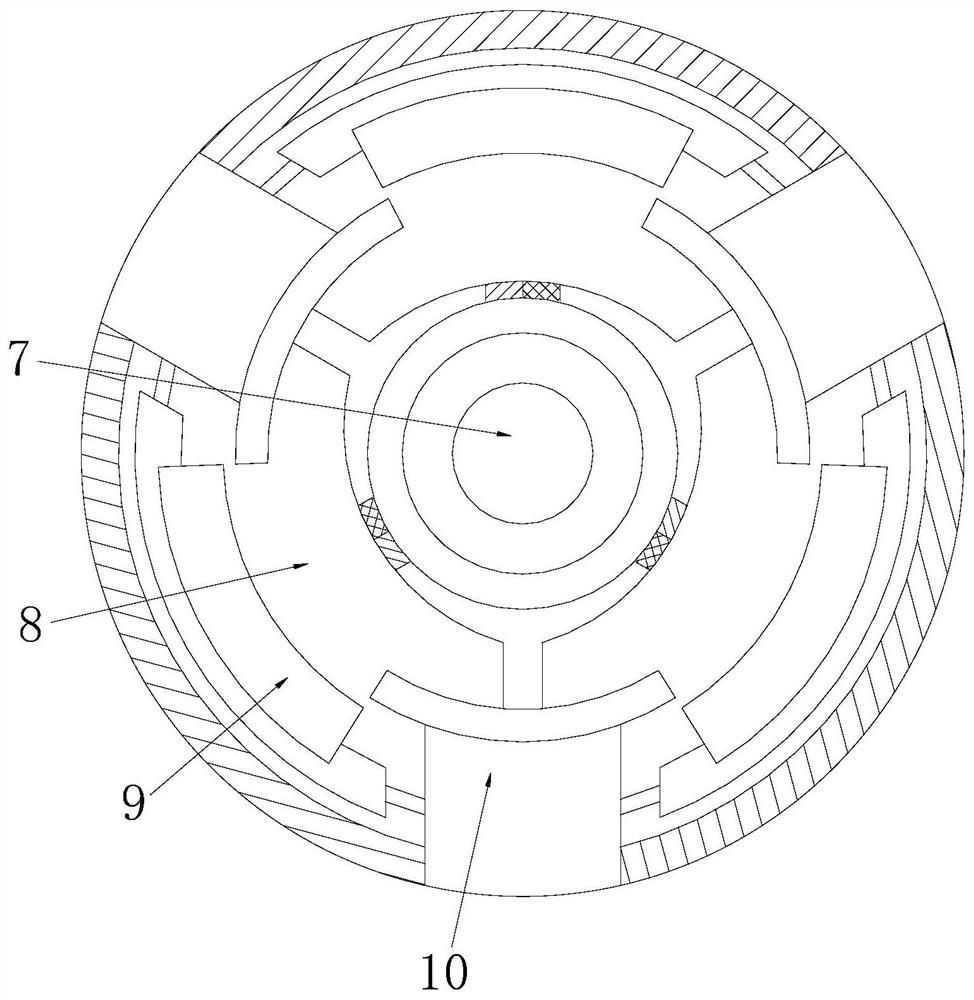

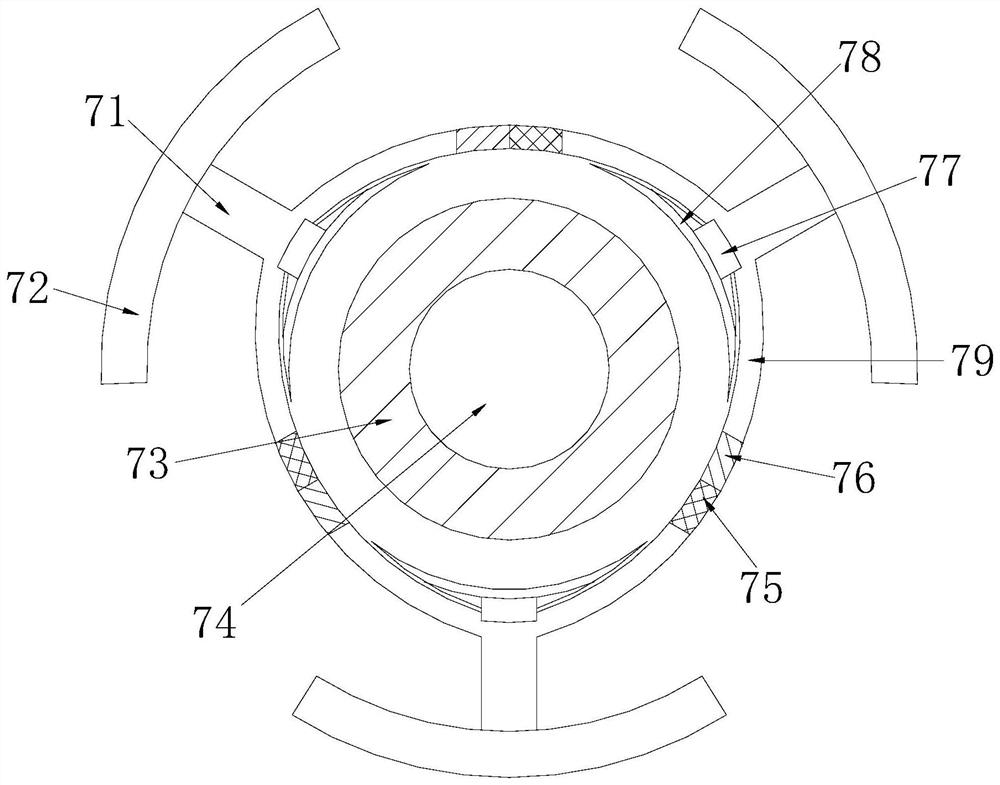

[0027] The adapter 4 is composed of a matching head 7, a fitting cavity 8, a connecting block 9, and a fixing block 10. block 10 , the connecting block 9 and the fixing block 10 are distributed alt...

Embodiment 2

[0037] see Figure 1-Figure 3 , the present invention provides an automatic filling machine for normal-pressure liquids, the structure of which includes a hopper 1, an upper plate 2, a liquid storage chamber 3, an adapter 4, a fixing frame 5, and a workbench 6, and the hopper 1 is arranged on the upper layer On the top of the plate 2, the feeding bucket 1 communicates with the liquid storage cavity 3 through the upper plate 2, the liquid storage cavity 3 is installed in the south direction of the upper plate 2, the fixed frame 5 is mechanically welded with the workbench 6, and the fixed The frame 5 is fixedly connected with the upper plate 2, the workbench 6 is installed in the south direction of the adapter 4, and the adapter 4 communicates with the liquid storage chamber 3; the adapter 4 is composed of a matching head 7, a fitting chamber 8, The connecting block 9 and the fixing block 10 are formed, the matching head 7 is located in the center of the fitting cavity 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com