Optimal selection method for roof cutting pressure relief gob-side entry retaining ventilation mode

A technology of roof cutting, pressure relief and ventilation, which is applied in mine/tunnel ventilation, earthwork drilling, complex mathematical operations, etc. It can solve problems such as failure to completely seal goafs, achieve stable wind flow, strong disaster resistance, Technically Advanced Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

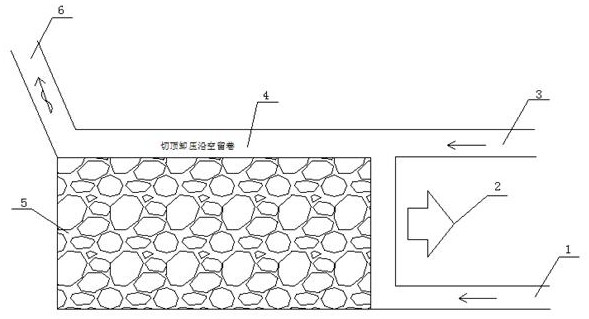

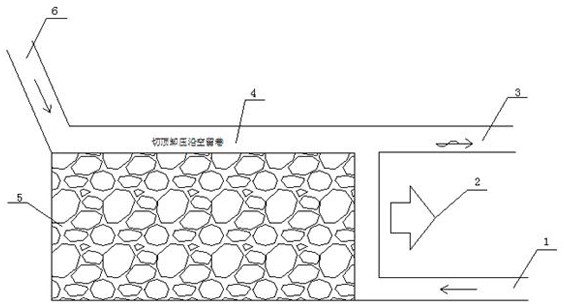

[0019] The present invention provides an optimal method for roof cutting, pressure relief and gob-side entry ventilation. Firstly, according to geological information parameters: coal seam thickness, coal seam dip angle α, coal seam direction, gas parameters, hydrological conditions and other parameters required during construction, a detailed ventilation implementation plan is formulated. Do a good job in the preparatory work before implementation, and consider dealing with cracks, faults, water and other risk factors.

[0020] A method for optimizing roof cutting and pressure relief along gob-side entry ventilation, comprising the following steps:

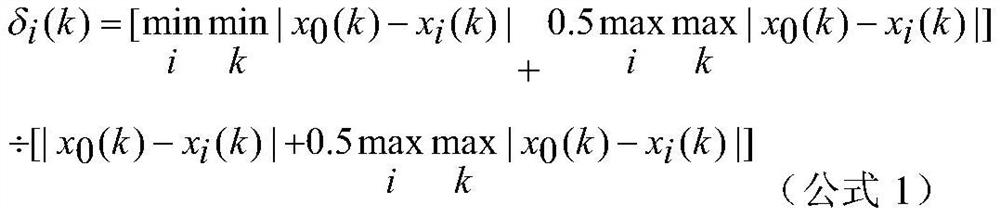

[0021] Step 1: Determine the comparison data column; determine the number n of ventilation schemes and the number m of influencing factors of the working face after roof cutting and pressure relief and gob-side entry retention; formulate based on the value of the i-th scheme at the K-th influencing factor compare data column {x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com