Modular design gearbox and gear realization method

A technology of modular design and implementation method, applied in the field of gearbox, can solve the problem that the gearbox cannot meet the requirements of forward 8 gears and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Exemplary embodiments of the present invention are described below in conjunction with the accompanying drawings, which include various details of the embodiments of the present invention to facilitate understanding, and they should be regarded as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted in the following description for clarity and conciseness.

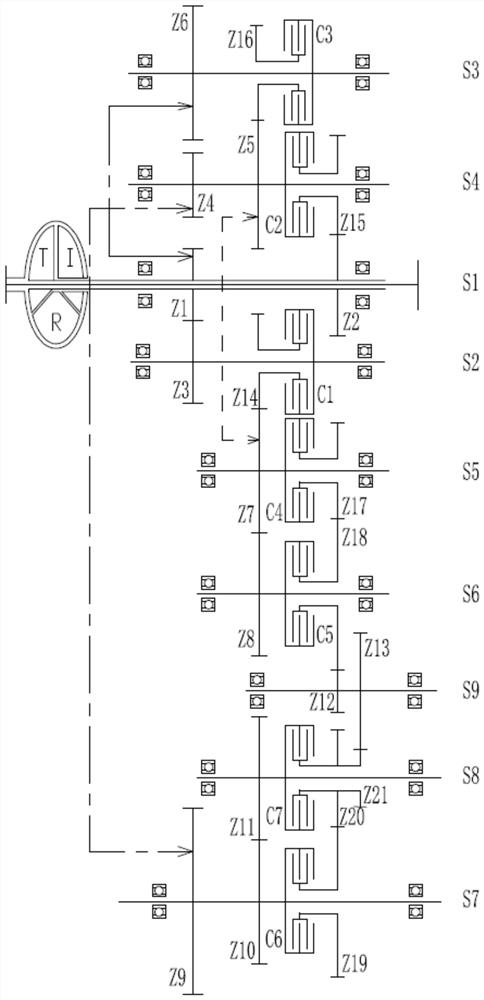

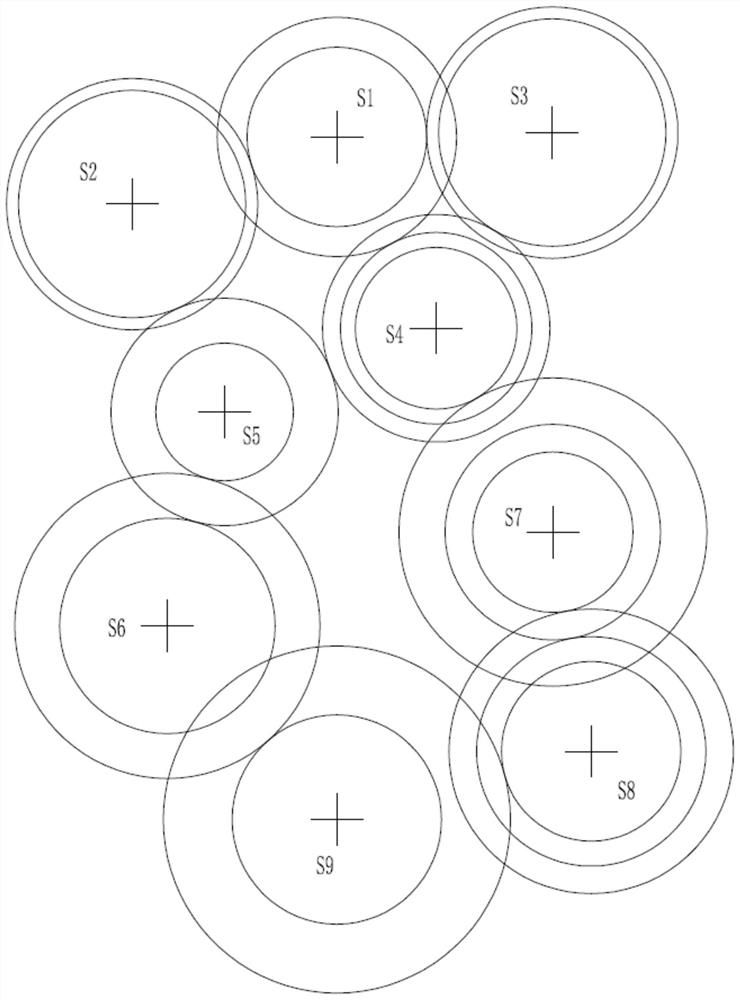

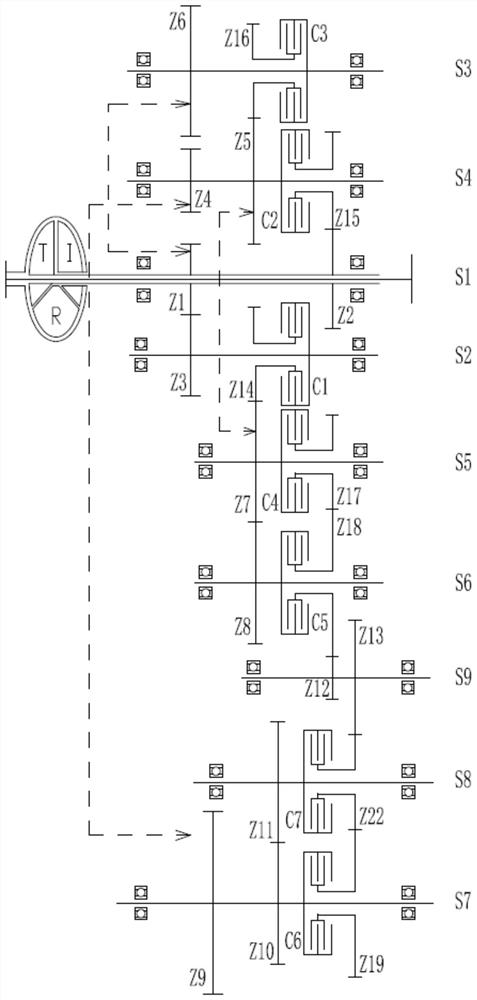

[0068] refer to figure 1 and figure 2 , the modular design gearbox of the present invention includes a box body and a drive shaft S1 arranged in the box body, intermediate shafts S2-S8 and an output shaft S9, wherein the drive shaft S1 is provided with a fixed gear Z1 and a fixed gear Z2; the middle The shaft S2 is provided with the fixed gear Z3 and the floating gear Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com