Linear control method for electric heater by DCS

A technology of electric heater and linear control, applied in electric controllers, controllers with specific characteristics, etc., can solve problems such as difficult to achieve expected control effect, large time lag of electric heaters, etc., to solve the problem of time lag , Reliable control and reliable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

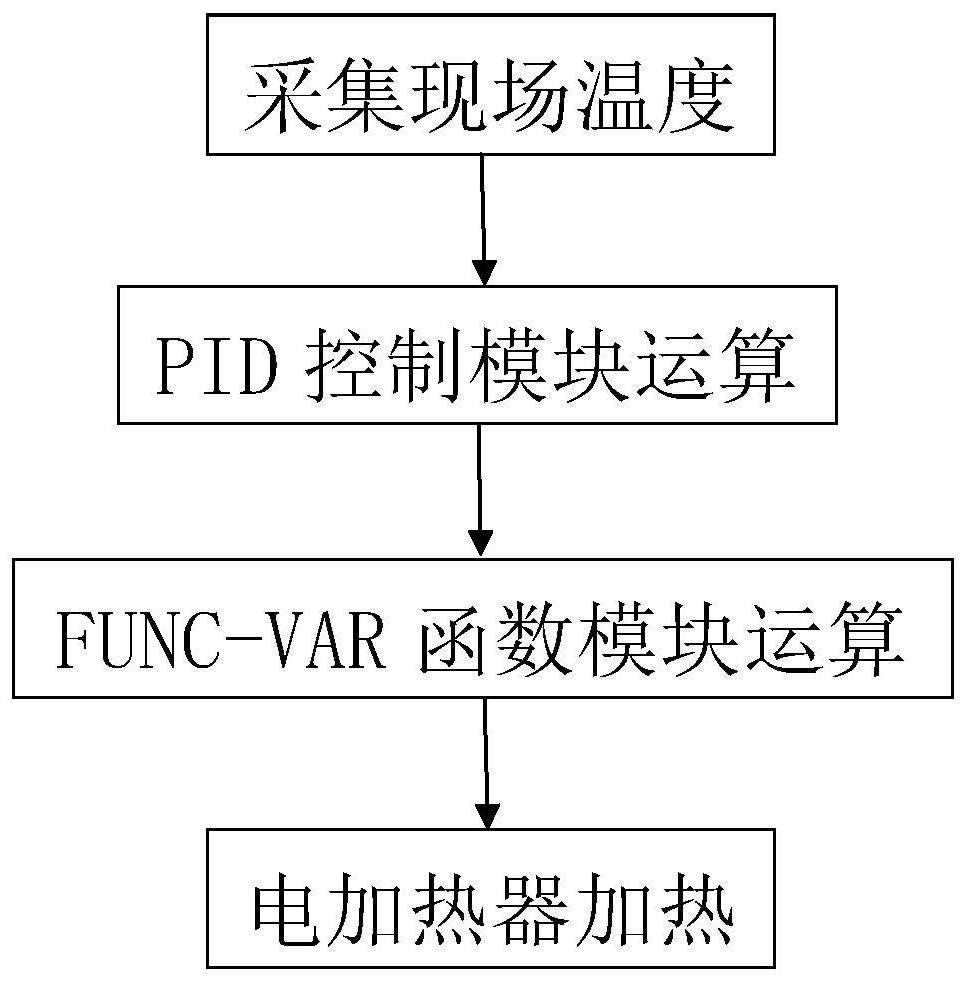

[0034] A DCS linear control method for electric heaters, such as figure 1 shown, including the following steps:

[0035] S1: The temperature sensor collects the temperature on site, and transmits the collected temperature information to the PID control module.

[0036] In this embodiment, the heating object of the electric heater is liquid. Liquids are mostly heated objects, and the models established by using liquids as objects are more universal.

[0037] S2: The PID control module outputs the manipulated variable MV after the PID control operation.

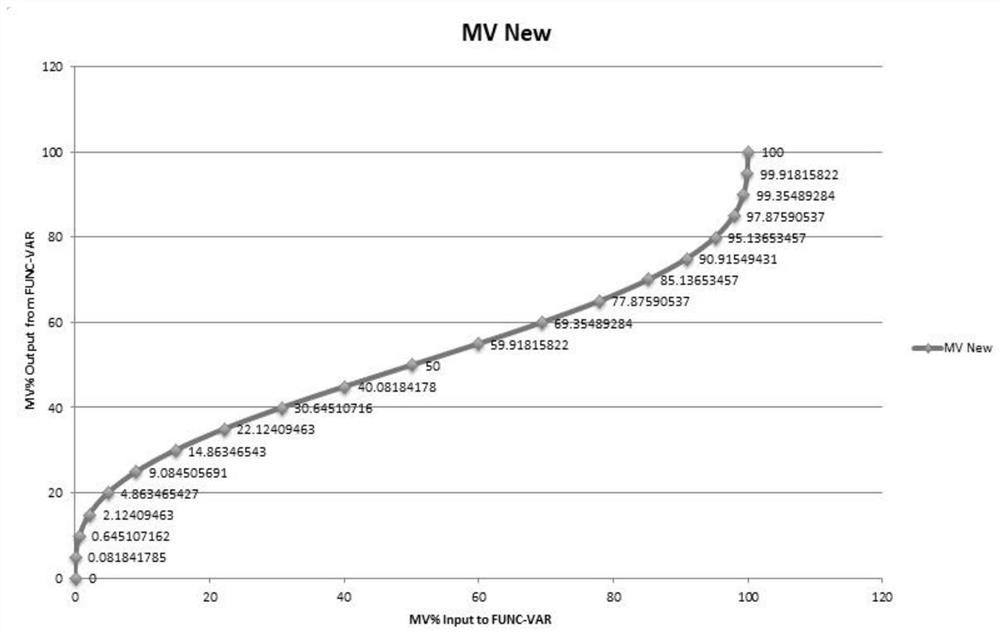

[0038] The manipulated variable MV is input to the FUNC-VAR function module as an input value, and the FUNC-VAR function module outputs a control quantity that is linear with the input after operation.

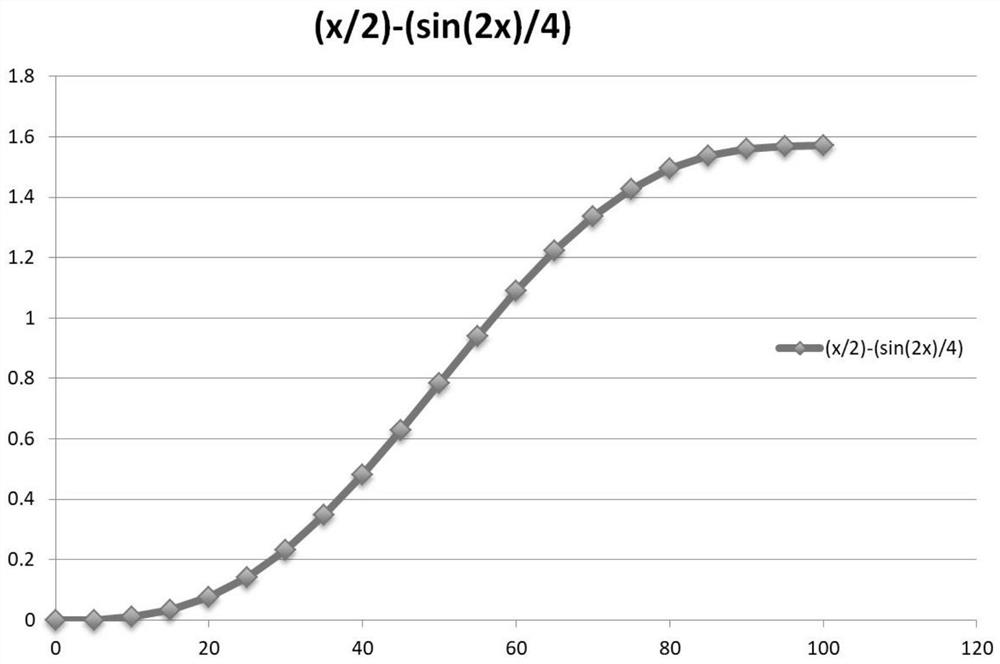

[0039] The operation function in the FUNC-VAR function module is a combination of at most seven segments of linear functions, and the linear function is f(x)=ax+b; wherein, a and b are constants.

[0040] The control funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com