A production interlock control method and system for an engine mixed-flow assembly line

A technology of interlock control and engine, applied in general control system, control/adjustment system, program control, etc., can solve the problems of limited effect, low efficiency, high error and omission rate, and achieve the prevention of missing writing, reducing assembly errors, and preventing errors and omissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

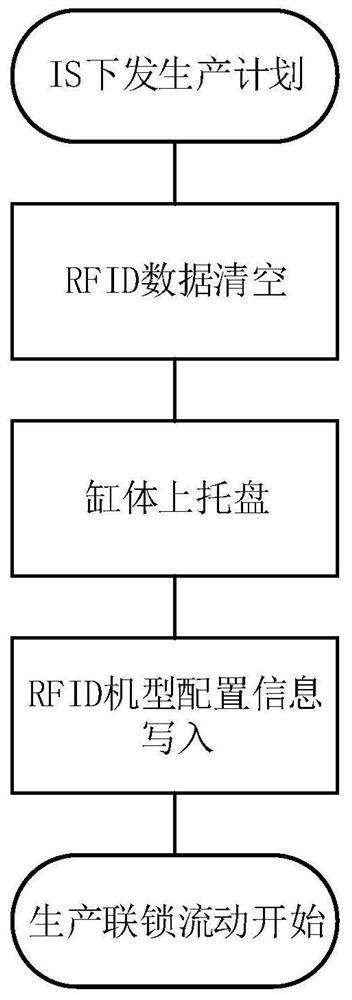

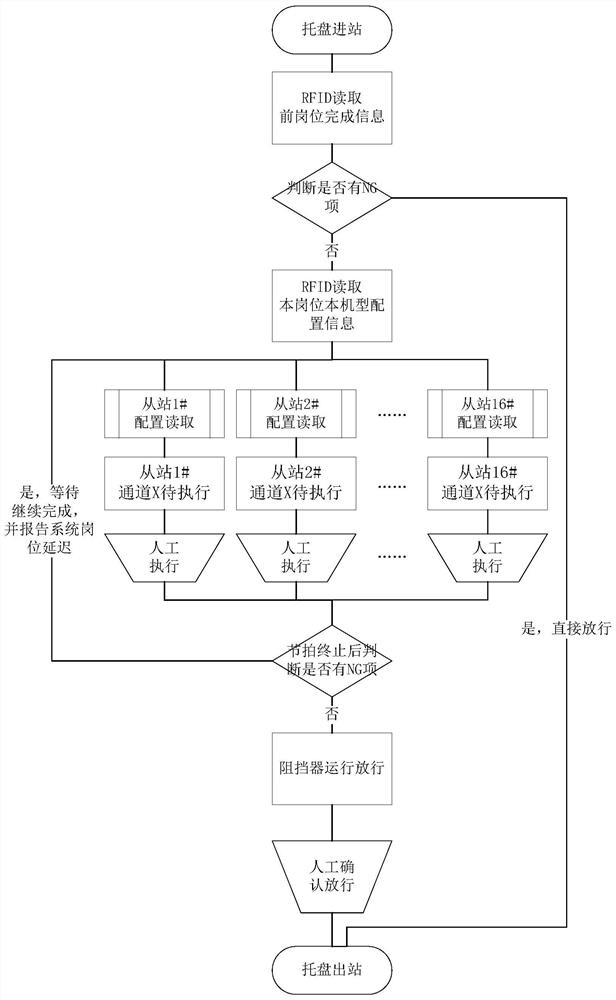

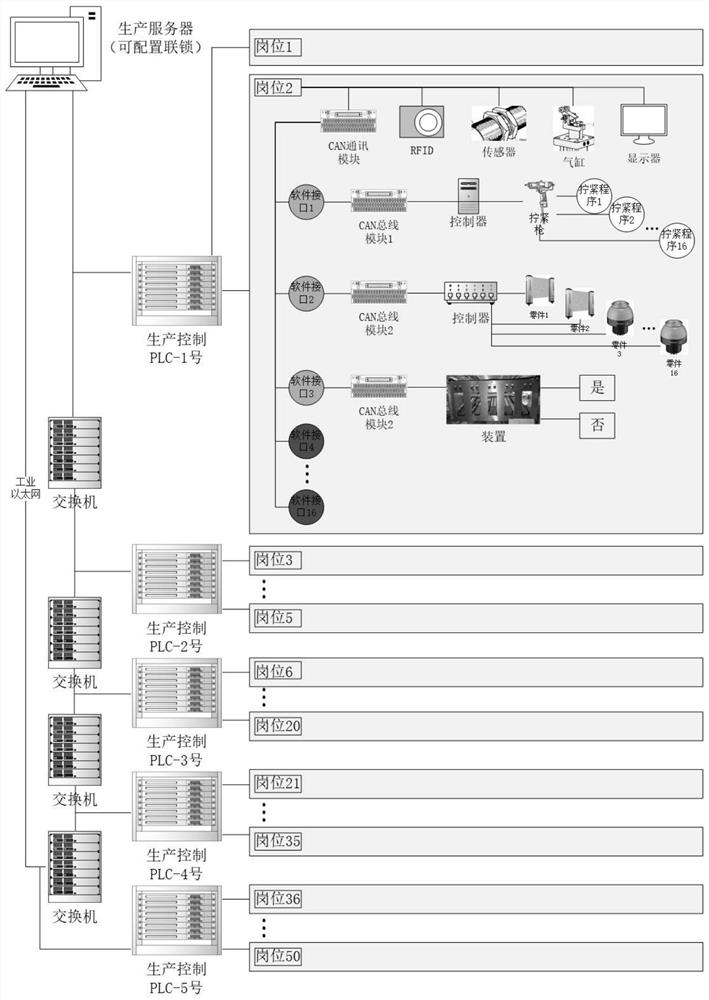

[0031] The present invention relates to a production interlocking control method of an engine mixed-flow assembly line, the control flow of which is as follows:

[0032] Install RFID cards on each pallet used to assemble the engine, and install a read-write head for reading and writing RFID card data at each engine assembly station;

[0033] Such as figure 1 As shown, when the production line starts, the interlocking control system server clears the data in the RFID card and sends the model interlocking configuration information to the RFID card. The model interlocking configuration information includes tool information and part information of the model to be assembled and action information;

[0034] The operator uses the read-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com