A Laser Shock Thin Plate Glue Rivet Composite Connection Method and Its Application

A technology of laser shock and composite connection, which is applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problems of aggregated flow of adhesive between boards, difficulty in riveting applications, and interlocking embedding volume, etc. problems, to achieve the effect of ensuring continuous and uniform distribution, small stress gradient, and easy riveting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0034] A thin-plate adhesive riveting compound connection method by laser shock, the laser beam adopts 700mJ YAG pulse laser, the pulse width is 8ns, the pulse frequency is 10Hz, and the laser beam diameter is 4mm.

[0035] The upper plate is a pure copper plate with a thickness of 0.03mm, and the lower plate is a pure aluminum plate with a thickness of 0.02mm.

[0036] The hole diameter of the holed mold used is 2.5mm.

[0037] The adhesive used was Henkel Teroson EP 5055.

[0038] Specific steps are as follows:

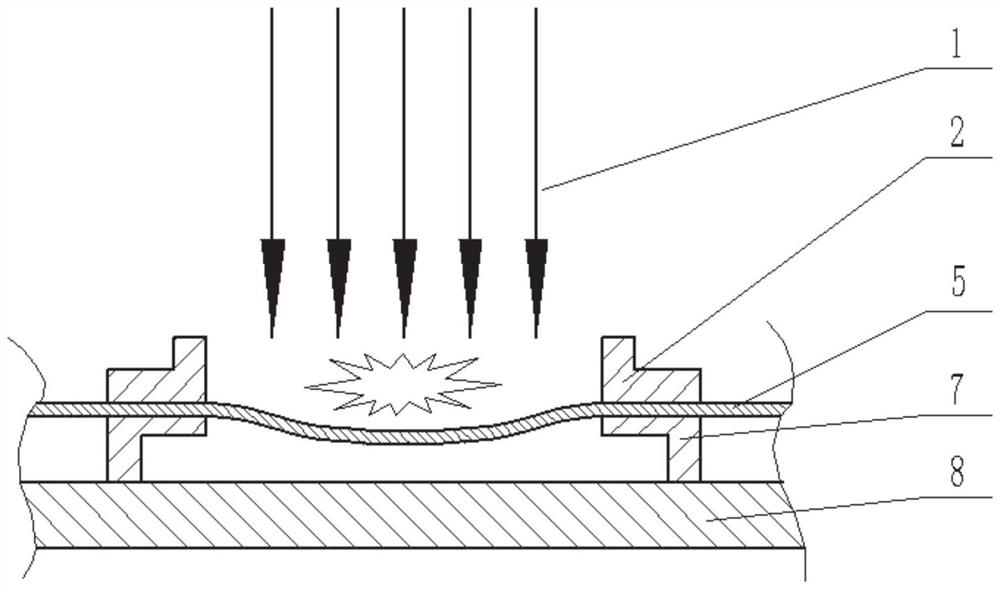

[0039] A. If figure 1 As shown, the lower plate 5 is placed on the mold 7 with a hole, and then clamped with the clamping device 2, and the pulsed laser beam 1 is used to impact the lower plate 5, so that the impact forming on the lower plate has a depth of 0.2mm. Then fill the pit with adhesive 6.

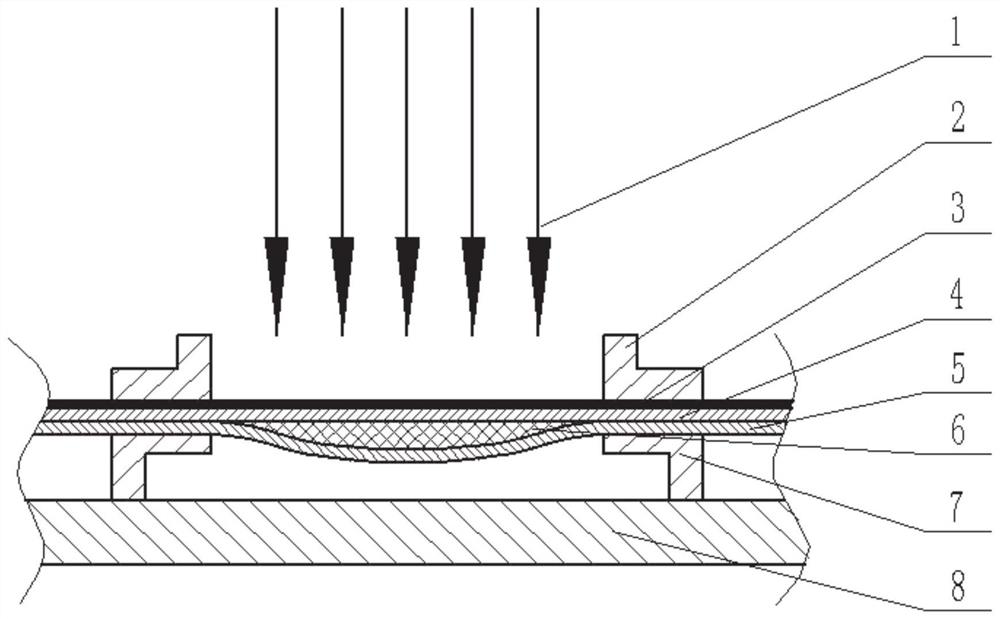

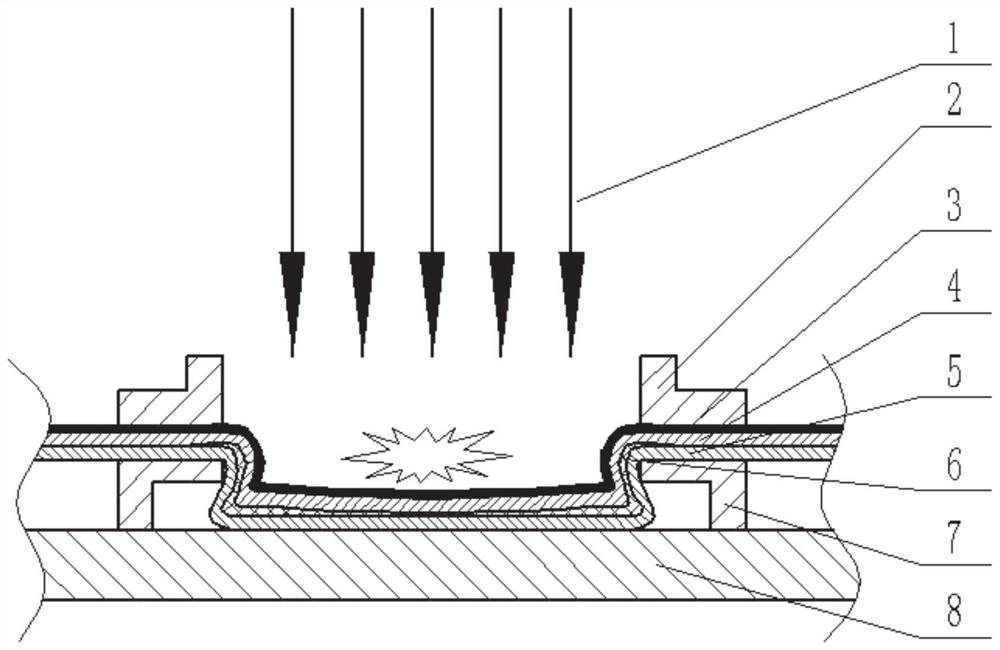

[0040] B. If figure 2 As shown, the upper surface of the upper plate 4 is coated with paraffin wax as the energy absorbing layer 3, and the upper plate 4 and the lo...

no. 2 example

[0044] A thin-plate adhesive riveting compound connection method by laser shock, the laser beam adopts 1000mJ YAG pulse laser, the pulse width is 8ns, the pulse frequency is 10Hz, and the laser beam diameter is 6mm.

[0045] The upper plate is a pure copper plate with a thickness of 0.03mm, and the lower plate is a pure copper plate with a thickness of 0.03mm.

[0046] The hole diameter of the holed mold used is 4mm.

[0047] Adhesive adopts HUITIAN 6011 one-component heat curing epoxy adhesive for structural bonding.

[0048] Specific steps are as follows:

[0049] A. If figure 1 As shown, the lower plate 5 is placed on the mold 7 with a hole, and then clamped with the clamping device 2, and the pulsed laser beam 1 is used to impact the bulging of the lower plate 5, so that the impact forming on the lower plate has a depth of 0.3mm. Then fill the pit with adhesive 6.

[0050] B. If figure 2 As shown, the upper surface of the upper plate 4 is coated with black paint as t...

no. 3 example

[0054] A laser-shock thin-plate adhesive riveting compound connection method, the laser beam adopts 1200mJ YAG pulse laser, the pulse width is 8ns, the pulse frequency is 10Hz, and the laser beam diameter is 6mm.

[0055] The upper plate is a pure copper plate with a thickness of 0.05mm, and the lower plate is a pure aluminum plate with a thickness of 0.05mm.

[0056] The hole diameter of the holed mold used is 4 mm.

[0057] The adhesive used was Henkel Teroson EP 5055.

[0058] Specific steps are as follows:

[0059] A. If figure 1 As shown, the lower plate 5 is placed on the mold 7 with holes, and then clamped with the clamping device 2, and the pulsed laser beam 1 is used to impact the lower plate 5, so that the impact forming on the lower plate has a depth of 0.6mm. Then fill the pit with adhesive 6.

[0060] B. If figure 2 As shown, the upper surface of the upper plate 4 is coated with paraffin wax as the energy absorbing layer 3, and the upper plate 4 and the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com