Portable high-speed thermal printer

A technology of thermal printers and printers, applied in printing devices, printing, etc., can solve the problems of poor dust-proof effect, dust impurities entering, affecting the overall use, etc., to ensure printing performance, ensure sealing and dust-proof effects, and be easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

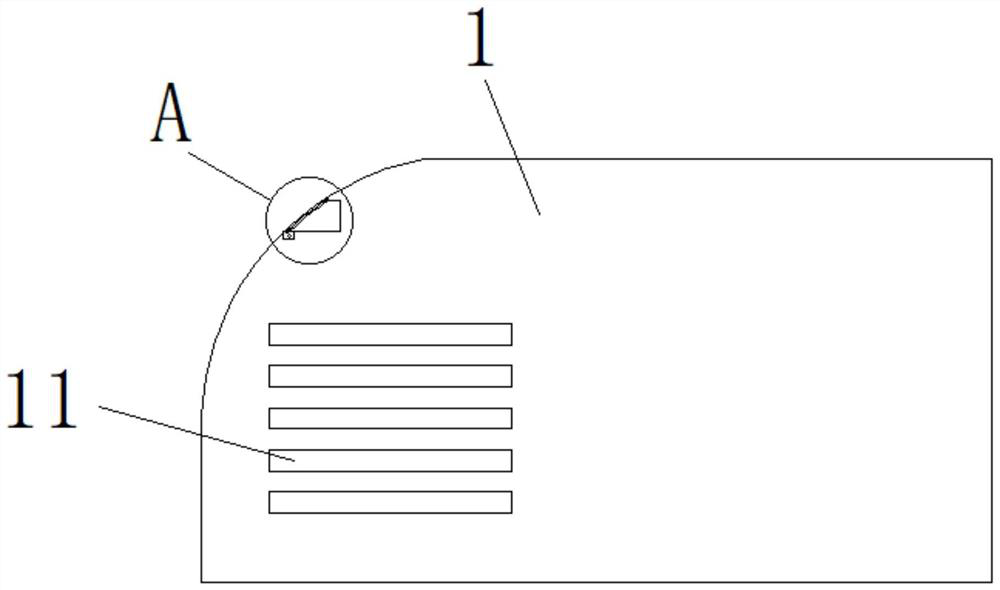

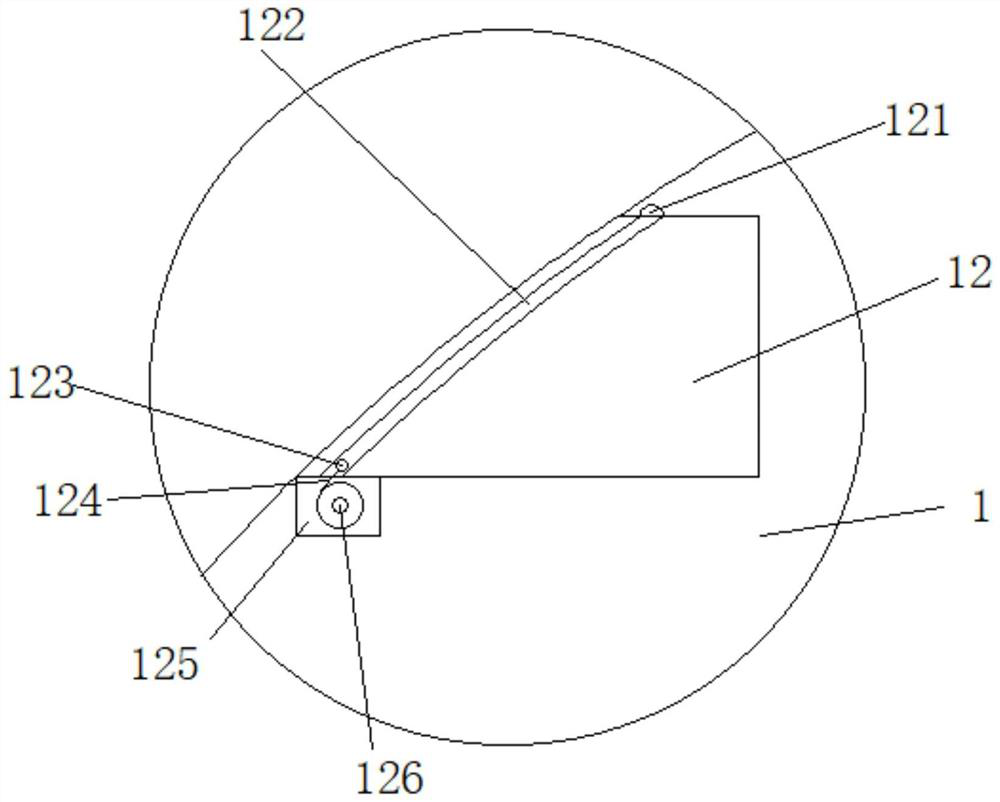

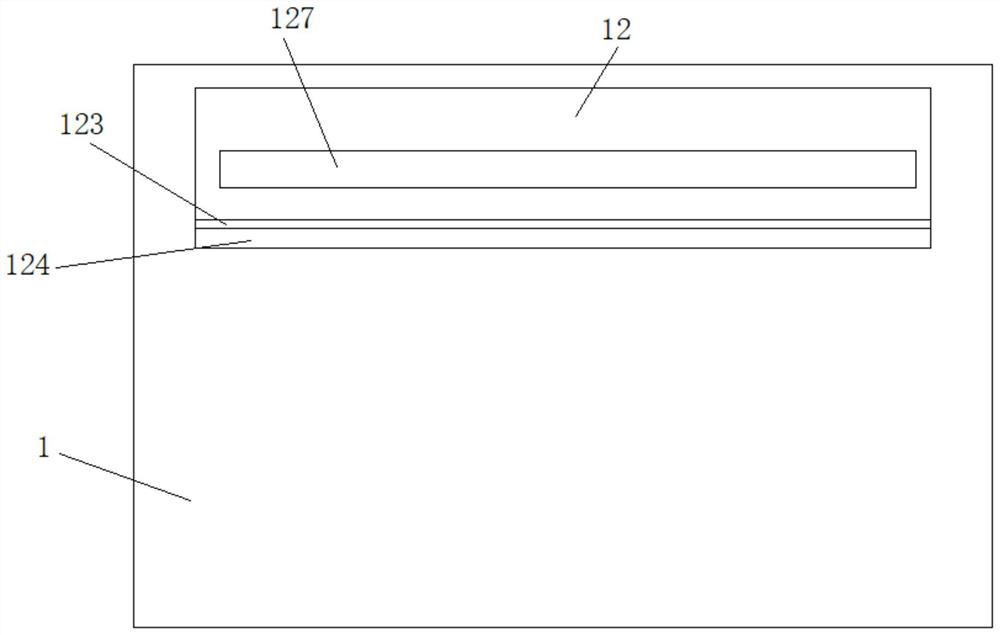

[0024] see Figure 1-4 , a portable high-speed thermal printer, comprising a printer main body 1, a print outlet 127 arranged on the printer main body 1, an outlet slot 12 is arranged on the printer main body 1 at the print outlet 127, and all print outlets outside the print outlet 127 The two side walls of the outlet groove 12 are provided with symmetrically distributed chute 122, and a sealing rod 123 for sliding connection is arranged between the chute 122. The printer main body 1 at the bottom of the outlet groove 12 is provided with an outlet groove 12 is connected with the adjustment groove 125, the adjustment groove 125 is provided with a rotatably connected adjustment roller 126, and the adjustment roller 126 is provided with a sealing tape 124 that is evenly wound and used for sealing the outlet groove 12, and the sealing tape The extended end of 124 is connected and fixed with the sealing rod 123. There are a plurality of symmetrically distributed heat dissipation ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com