A fluid-solid coupling four-stage collision energy absorbing device

A collision energy absorption, fluid-structure coupling technology, applied in transportation and packaging, bumpers, vehicle parts, etc., can solve the problems of low energy absorption rate, unstable deformation mode, weak anti-defect ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

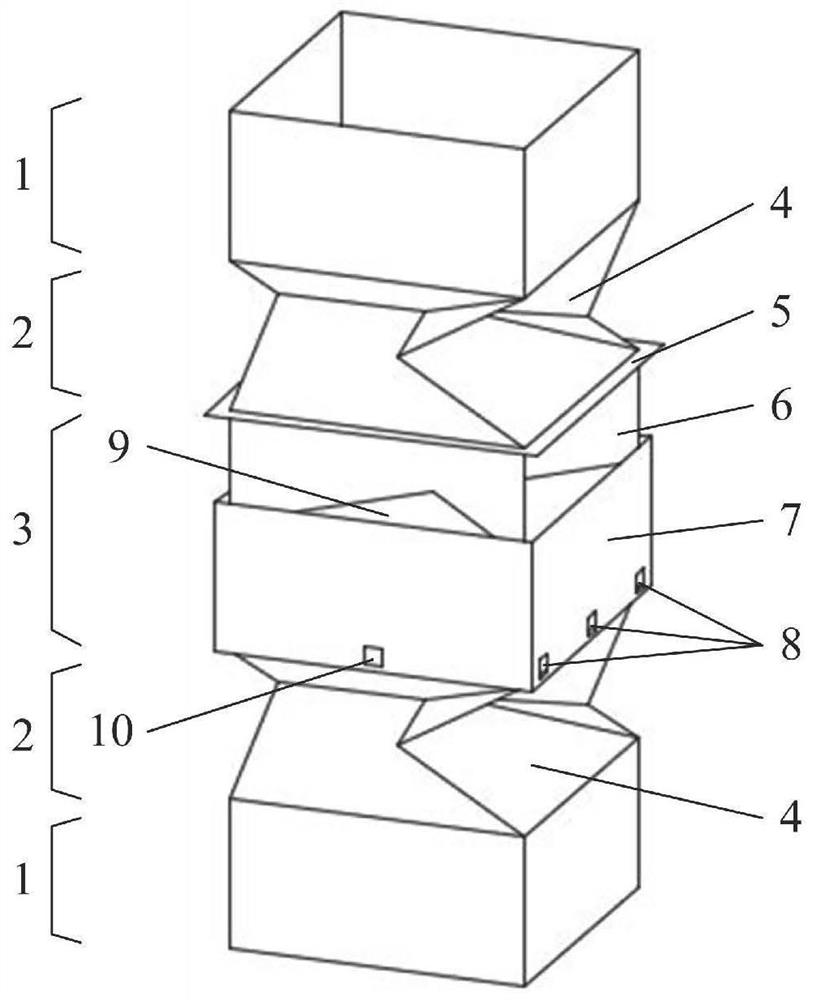

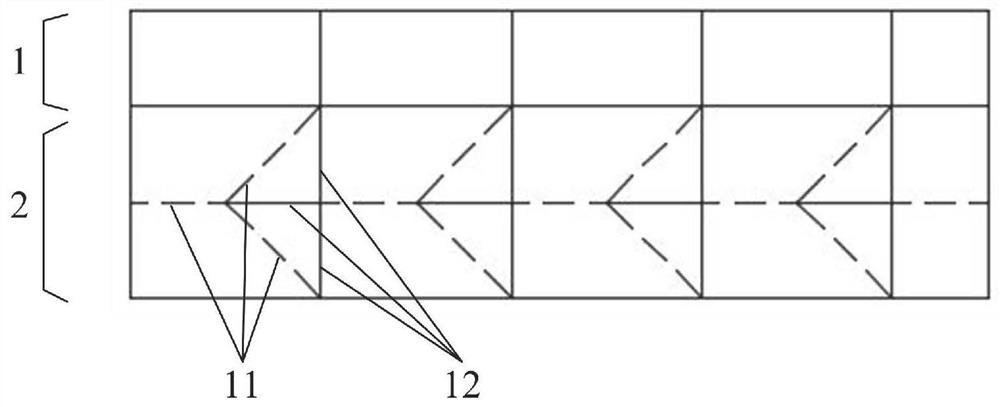

[0034] The present invention is a fluid-solid coupling four-stage collision energy-absorbing device, the structure of which is as follows figure 1 As shown, the collision energy-absorbing device is composed of a three-dimensional energy-absorbing area 1 , a folding energy-absorbing area 2 and a fluid energy-absorbing area 3 . The three-dimensional energy-absorbing area 1, the folded energy-absorbing area 2 and the fluid energy-absorbing area 3 are arranged in a cross arrangement from top to bottom. Collision energy-absorbing devices of different heights can be obtained by superimposing several three-dimensional energy-absorbing areas 1 , folded energy-absorbing areas 2 and fluid energy-absorbing areas 3 in the axial direction. In this embodiment, the three-dimensional energy-absorbing area 1 is a thin-walled pipe with a quadrilateral cross section. The folded energy-absorbing area 2 forms circularly arranged rotary folded concave corners 4 through the crease pattern and combi...

Embodiment 2

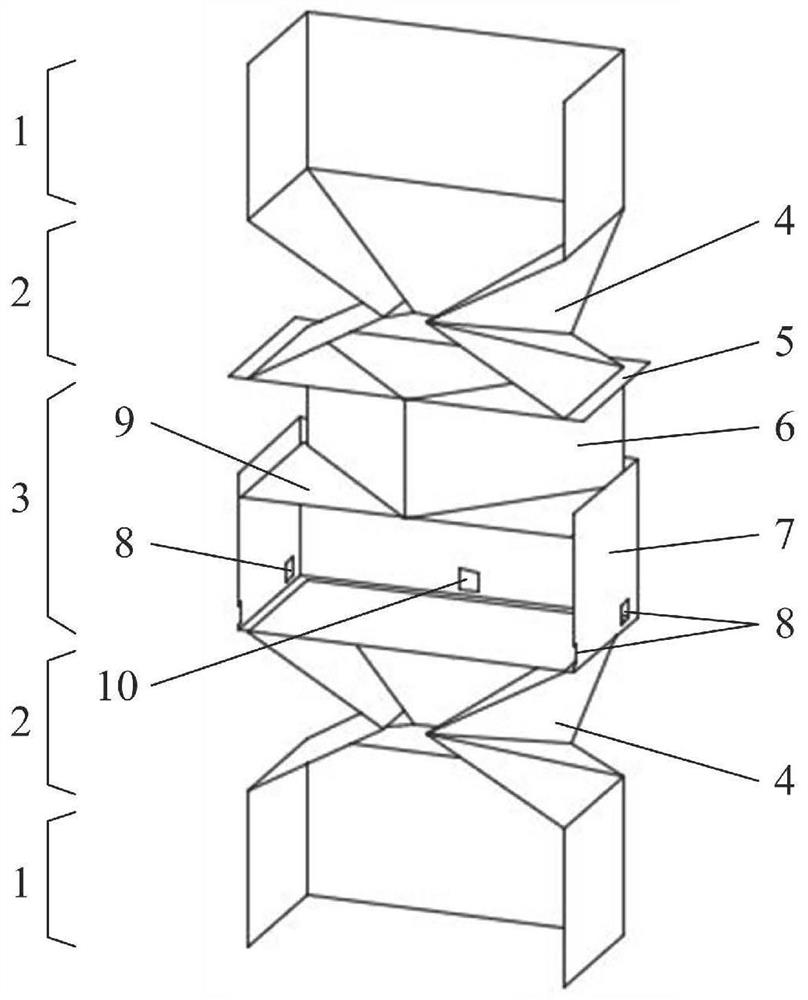

[0038]The present invention is a fluid-solid coupling four-stage collision energy-absorbing device, the structure of which is as follows Figure 4 As shown, the collision energy-absorbing device is composed of a three-dimensional energy-absorbing area 1 , a folding energy-absorbing area 2 and a fluid energy-absorbing area 3 . The three-dimensional energy-absorbing area 1, the folded energy-absorbing area 2 and the fluid energy-absorbing area 3 are arranged in a cross arrangement from top to bottom. In this embodiment, the three-dimensional energy-absorbing area 1 is a thin-walled pipe with a quadrilateral cross section. The folded energy-absorbing area 2 forms circularly arranged rotary folded concave corners 4 through the crease pattern and combined with the rotating folding method. In this embodiment, the collision energy-absorbing device is arranged with two folded energy-absorbing regions 2 , and the rotation directions of the folded concave corners 4 of the two folded en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com