Multi-wavelength laser processing light path system of melting additive manufacturing equipment

An optical path system and laser processing technology, applied in the field of metal additive manufacturing, can solve the problems of reducing speed, reducing the service life of the optical path system, reducing the effective utilization rate of energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

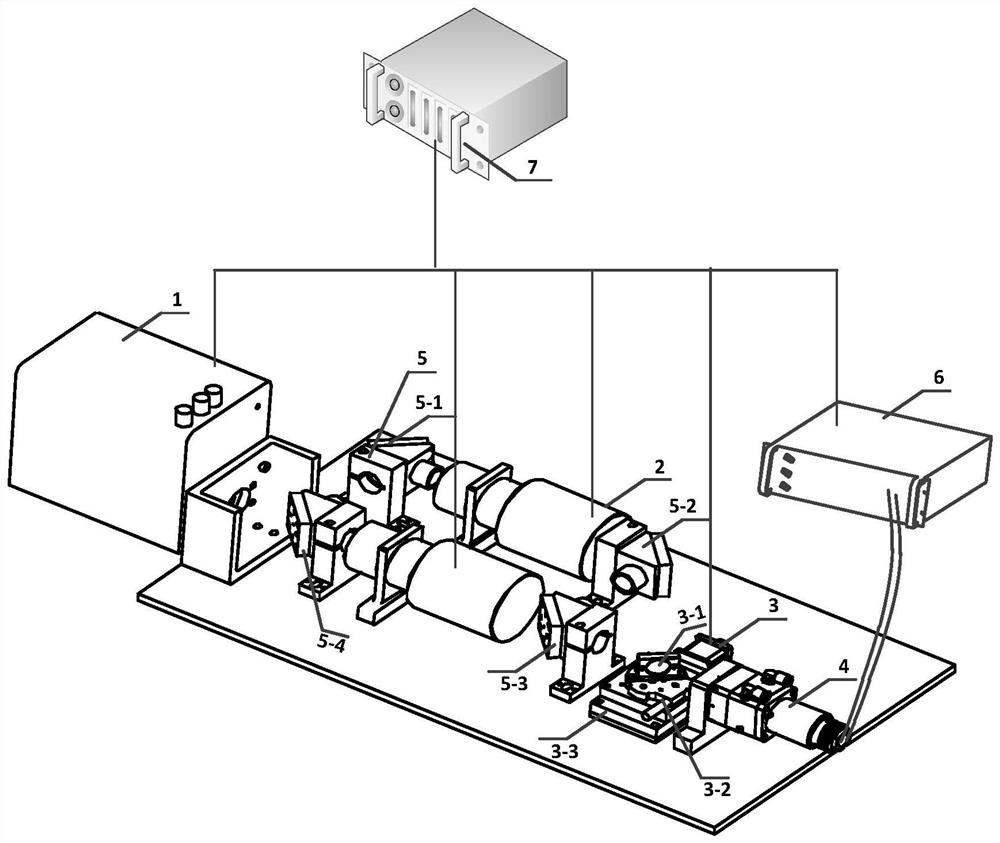

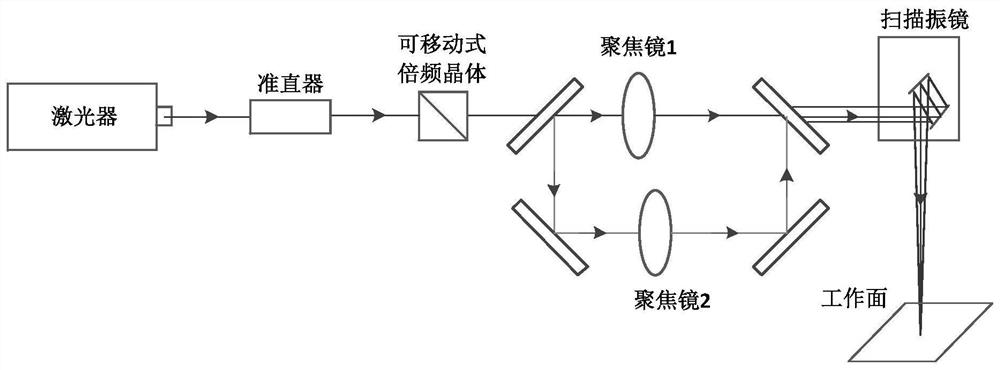

[0016] Such as figure 1 As shown, it is the multi-wavelength laser processing optical path system and device for selective melting additive manufacturing equipment according to the embodiment of the present invention. The device includes a scanning galvanometer 1, a dynamic focusing mirror 2, a movable frequency conversion device 3, a collimator 4, optical lens 5, laser 6, control system 7.

[0017] In the embodiment of the present invention, the scanning vibrating mirror 1 can meet the frequency bands before and after frequency conversion at the same time, ensuring that energy can reach the forming area during the metal sintering forming process. The laser 6 is usually a fiber laser in additive manufacturing equipment with a center wavelength of 1064nm, which is used to provide energy for metal powder melting.

[0018] In the embodiment of the present invention, there are two dynamic focusing mirrors 2, which are respectively used for focusing the beams before and after freq...

Embodiment approach 2

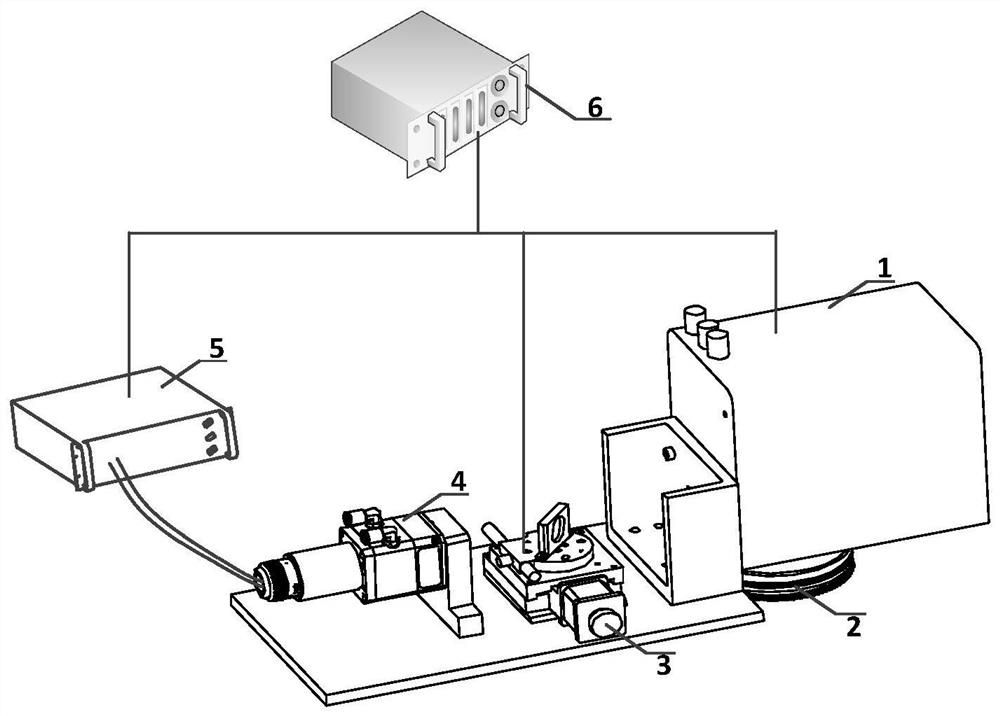

[0025] Such as figure 2 As shown, it is the multi-wavelength laser processing optical path system and device for selective melting additive manufacturing equipment according to the embodiment of the present invention. The device includes scanning galvanometer 1, achromatic focusing mirror 2, movable frequency conversion device 3, quasi- Straightener 4, laser 5, control system 6.

[0026] In the embodiment of the present invention, the achromatic focusing lens 2 also needs to meet the requirements of focusing the wavelength bands before and after frequency conversion on the same working plane at the same time, so that the beams of the two wavelength bands at different positions in the shaping area are uniform.

[0027] In the embodiment of the present invention, the control system 6 is used to control the normal operation of the scanning vibrating mirror 1 and the laser 5; at the same time, the control system 6 also controls the movable frequency conversion device 3, when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com