Cargo compartment floor lower energy absorption structural unit for improving crashworthiness of aircrafts

An energy-absorbing structure and cargo hold technology, applied in aircraft floors, aircraft parts, aircraft accessories, etc., can solve the problems of low energy loss rate and large weight cost of metal energy-absorbing structures, achieve low weight cost and improve resistance to lateral deformation. ability, improve the effect of energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The energy-absorbing structural unit under the cargo compartment floor for improving the crashworthiness of an aircraft provided by the present invention will be further described below with reference to the drawings and specific embodiments.

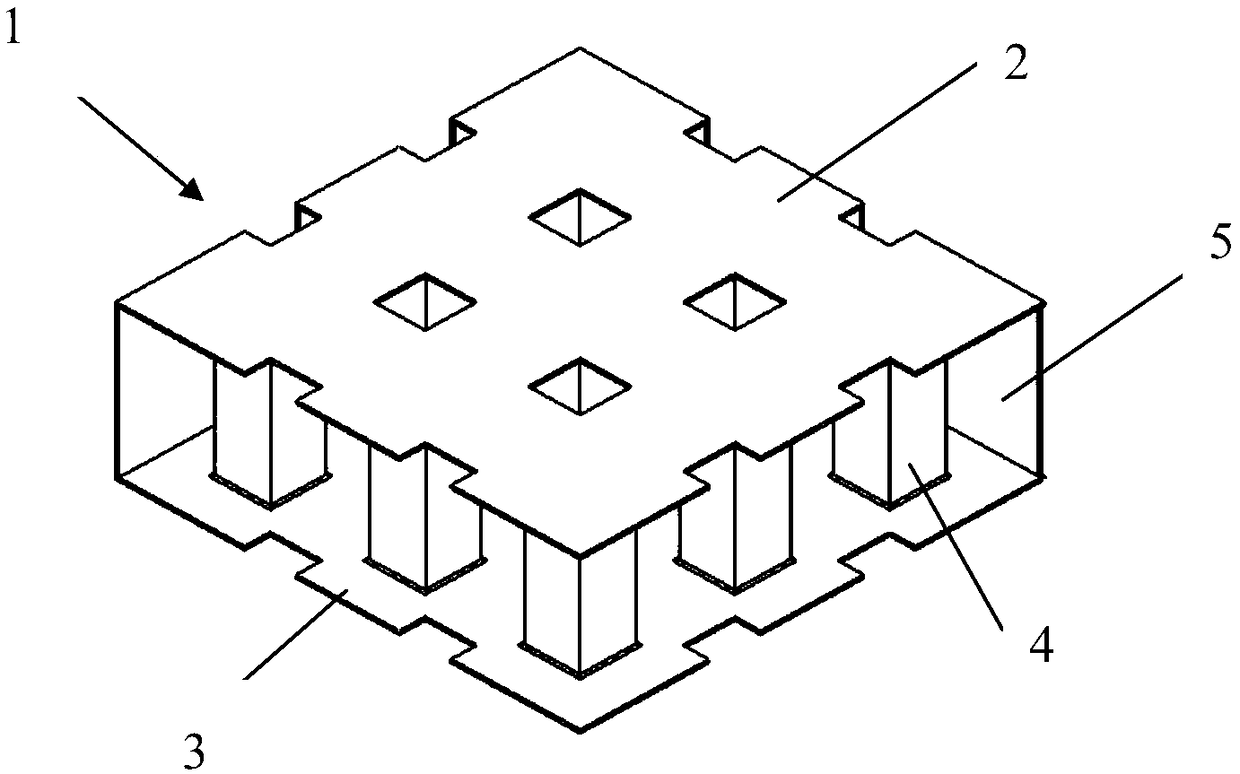

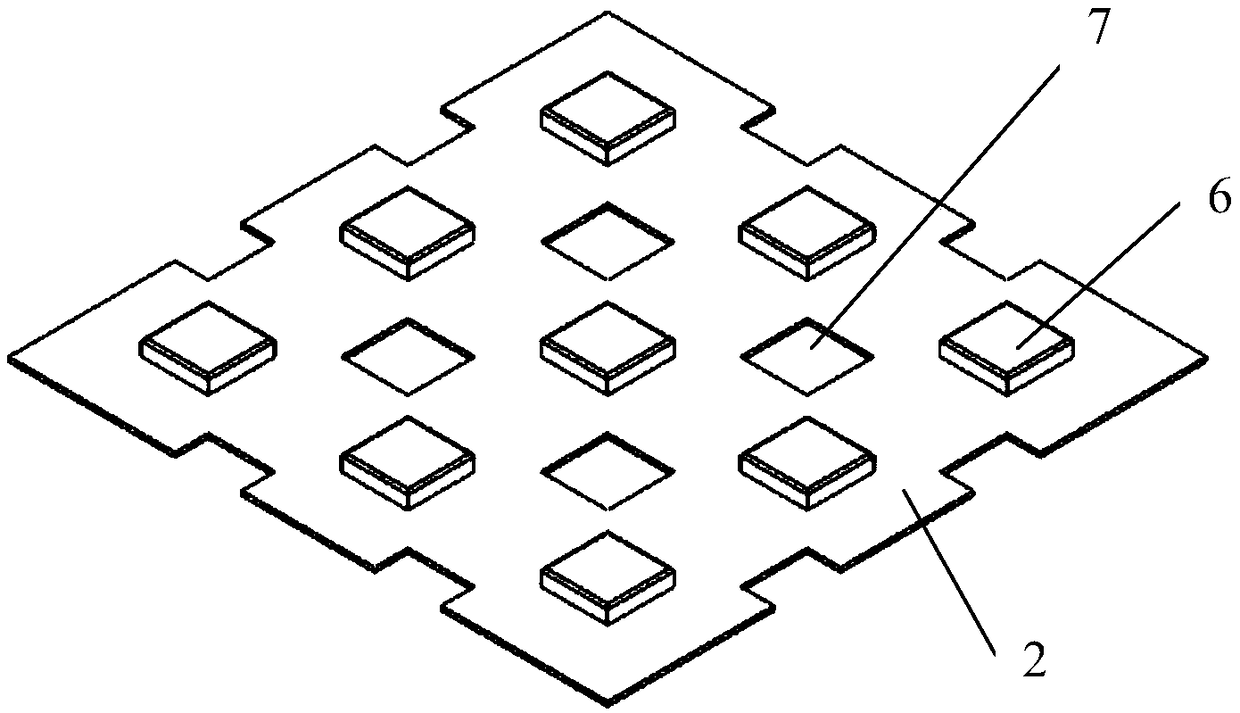

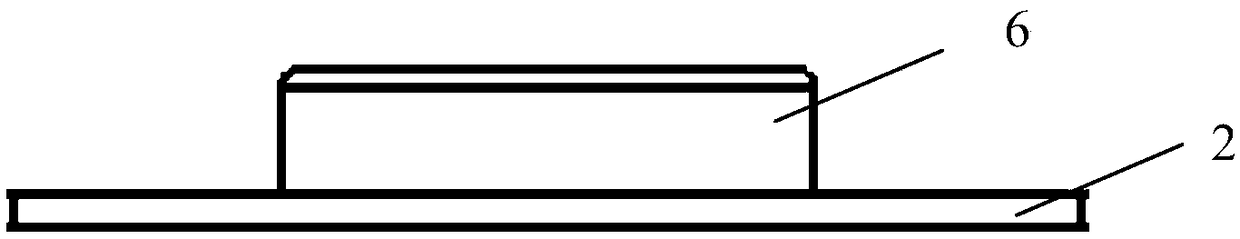

[0027] like figure 1 — Image 6 As shown, the energy-absorbing structural unit 1 of the lower part of the cargo floor for improving the crashworthiness of the aircraft provided by the present invention includes an upper panel 2, a lower panel 3, a plurality of composite material thin-walled square tubes 4 and a foam material layer 5; the upper panel 2 and the lower panel 3 are located on the upper and lower sides, wherein the bottom surface of the upper panel 2 is equidistantly provided with a plurality of upper bosses 6; the surface of the lower panel 3 is equidistantly provided with a plurality of lower bosses 8, and a plurality of upper bosses 6 The positions correspond to the positions of a plurality of lower bosses 8 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com