Foamed aluminum ribbed sandwich panel

A foamed aluminum, sandwich panel technology, applied in the direction of layered products, chemical instruments and methods, metal layered products, etc., can solve the problems of increased energy absorption and low energy absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

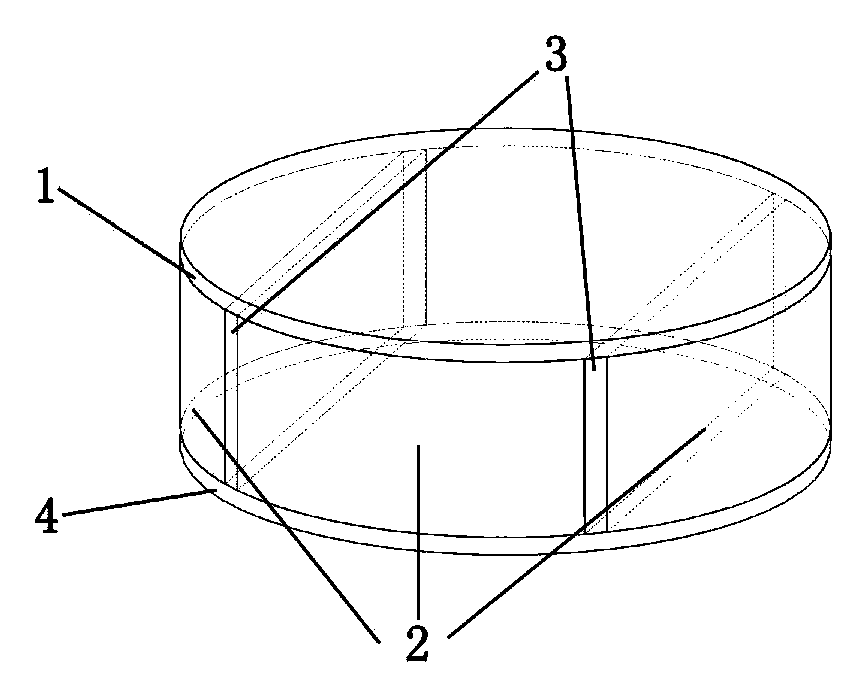

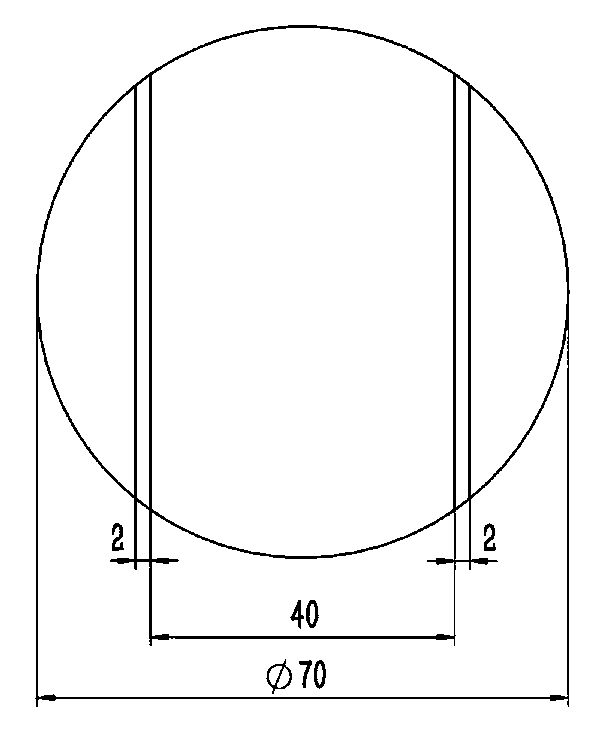

[0018] like figure 1 As shown, a foamed aluminum ribbed sandwich panel includes two aluminum panels, namely upper and lower aluminum panels 1 and 4, the two aluminum panels are identical, three pieces of foamed aluminum 2, two ribs 3, The ribs are made of aluminum material, and the specific shape is not limited. Two ribs are pasted parallel and symmetrically on the foamed aluminum, and then the two ribs and three pieces of foamed aluminum are formed with a high-strength metal adhesive to form a cross-section of the aluminum panel. The aluminum foam sandwich layer with the same shape and the same size, the cross-section of the aluminum panel in this embodiment is circular, so the aluminum foam sandwich layer is a round cake shape with a composite structure, and the two ribs are connected with the sandwich layer The top surface and the bottom surface are vertical, and then an aluminum panel is respectively bonded on the top surface and the bottom surface of the core layer with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com