Alignment device and method, film forming device and method, method for manufacturing electronic device, recording medium, and program

A technology of an alignment device and a film-forming device, which is applied in the manufacture of semiconductor/solid-state devices, electrical solid-state devices, electrical components, etc., can solve the problems of reduced precision, individual differences in masks, and offset of positional relationships, and achieves the goal of suppressing alignment The effect of reduced precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments and examples of the present invention will be described with reference to the drawings. However, the following embodiments and examples are merely illustrative of preferred structures of the present invention, and the scope of the present invention is not limited to these structures. In addition, in the following description, the hardware configuration and software configuration, processing flow, manufacturing conditions, dimensions, materials, shapes, etc. of the device are not intended to limit the scope of the present invention unless otherwise specified.

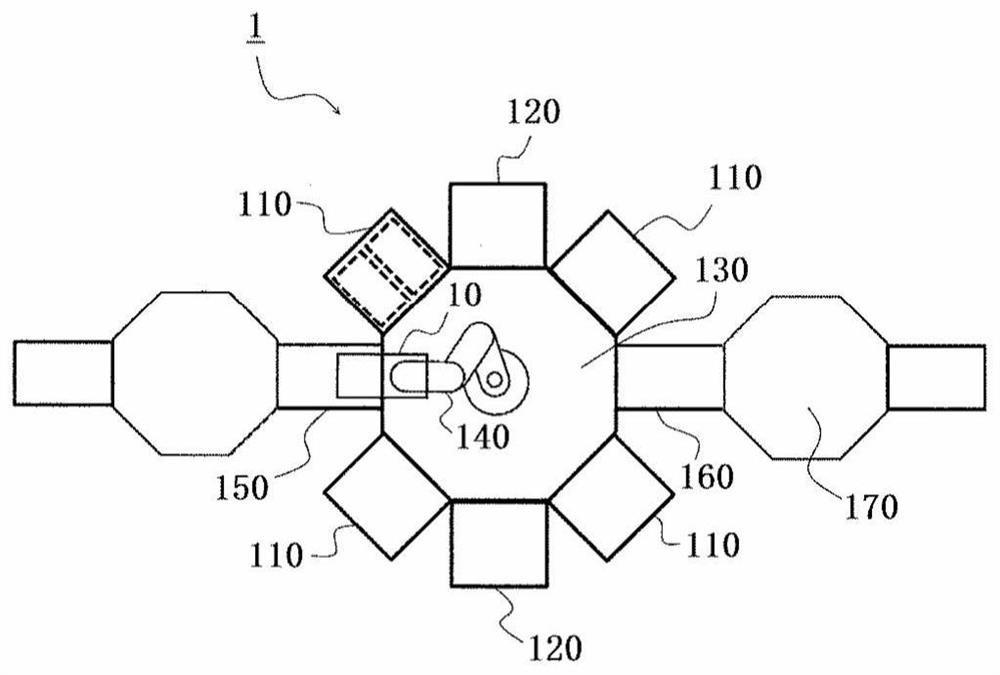

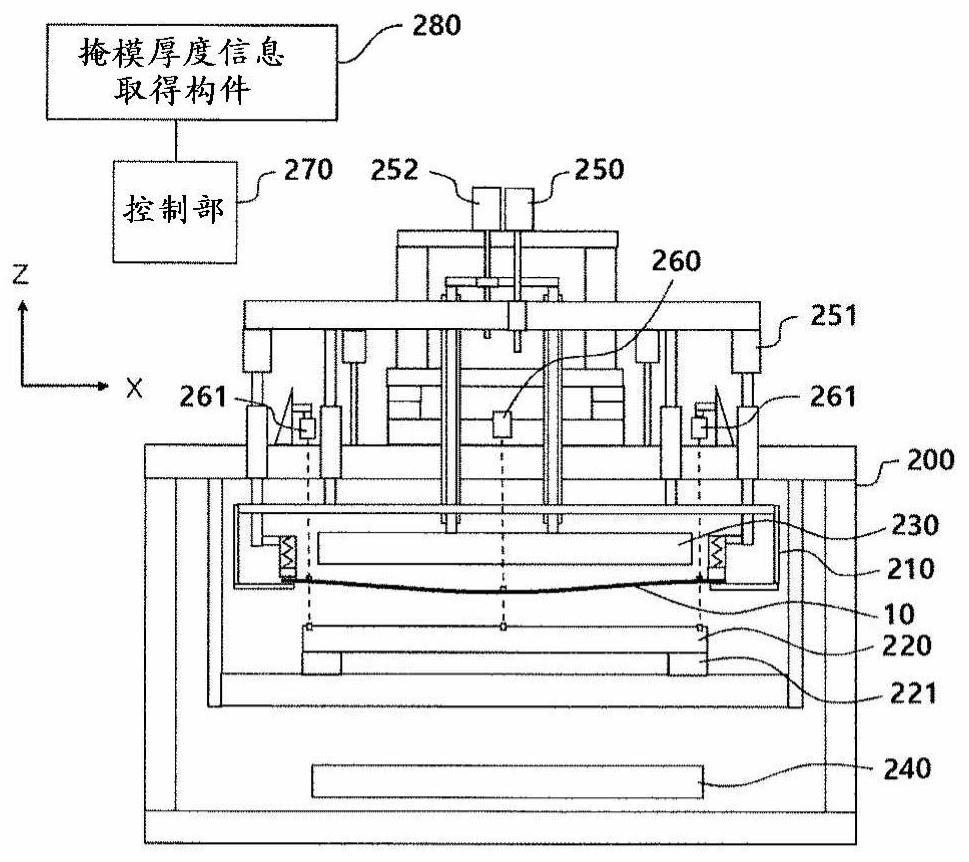

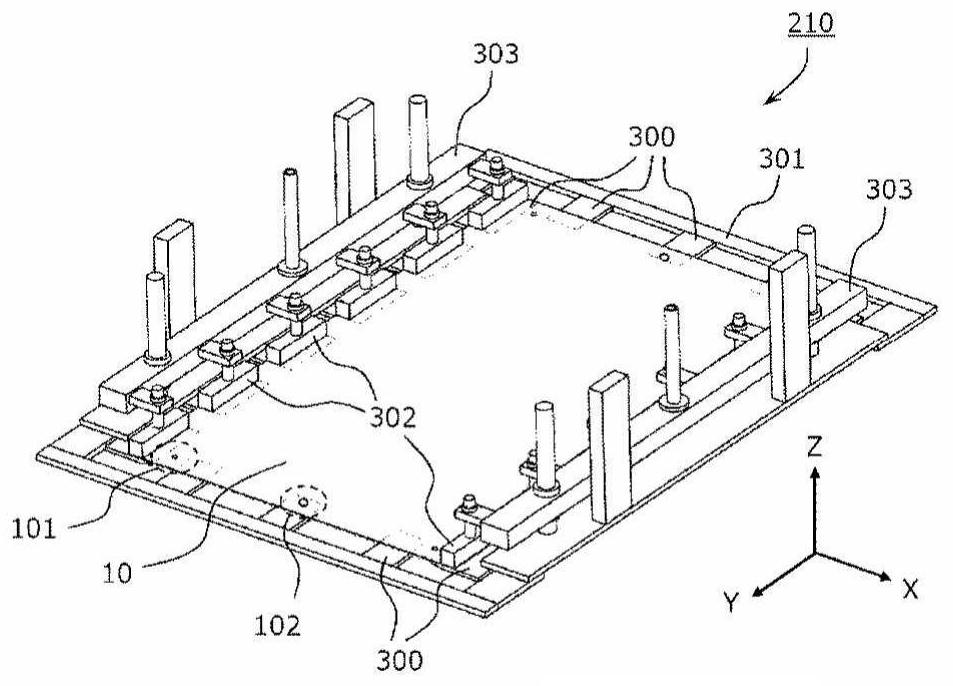

[0039] The present invention relates to a technique for high-precision position adjustment of a substrate. The present invention can be preferably applied to an apparatus for forming a thin film (material layer) of a desired pattern on the surface of a substrate by vacuum evaporation or sputtering. Any material such as glass, resin, or metal can be selected as the material of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com