Cable climbing robot

A robot and cable technology, applied in the field of cable detection equipment, can solve problems such as cable damage, low climbing speed, and affecting cable detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

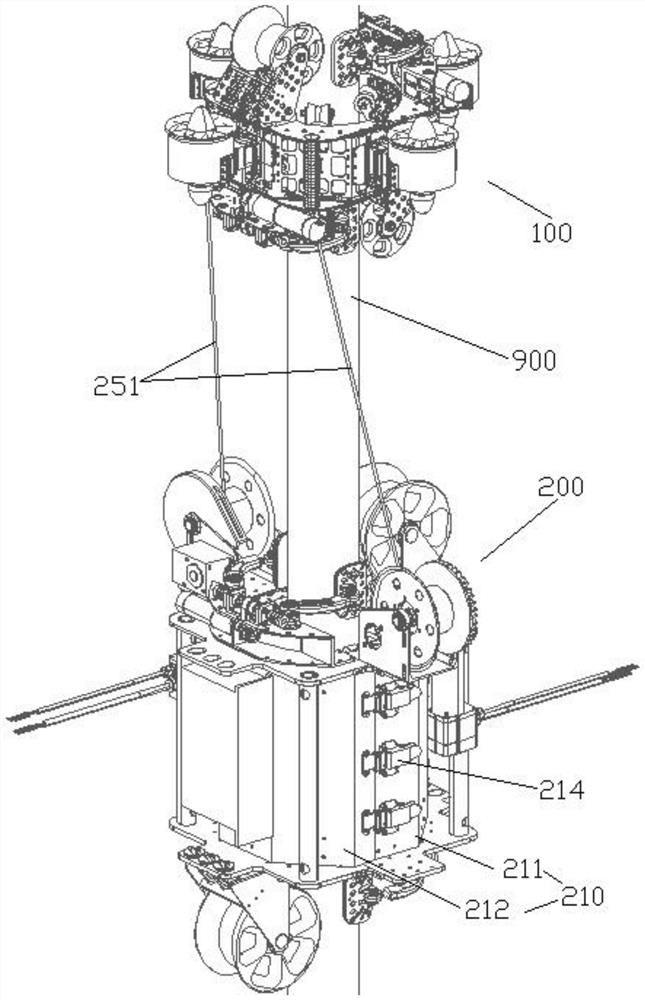

[0042] An embodiment of the present application provides a cable climbing robot, which is used to reduce the number of attachment times and the attachment pressure on the cable surface during the climbing process, thereby reducing the damage of the cable climbing robot to the cable surface.

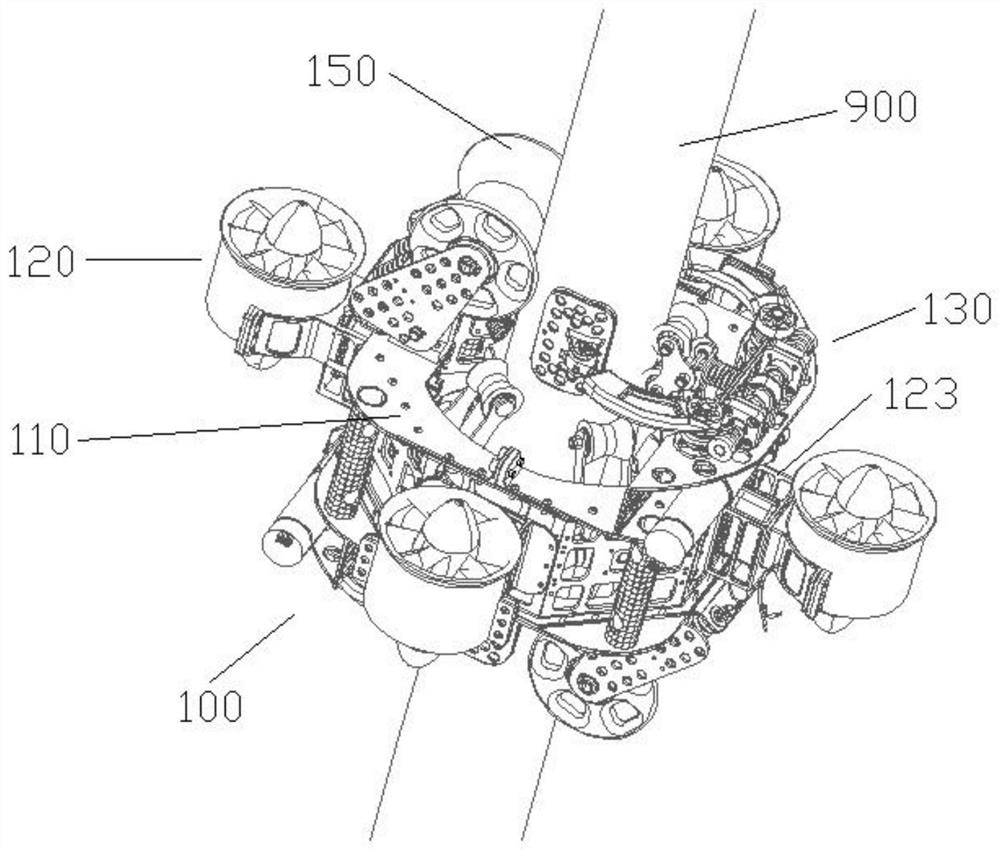

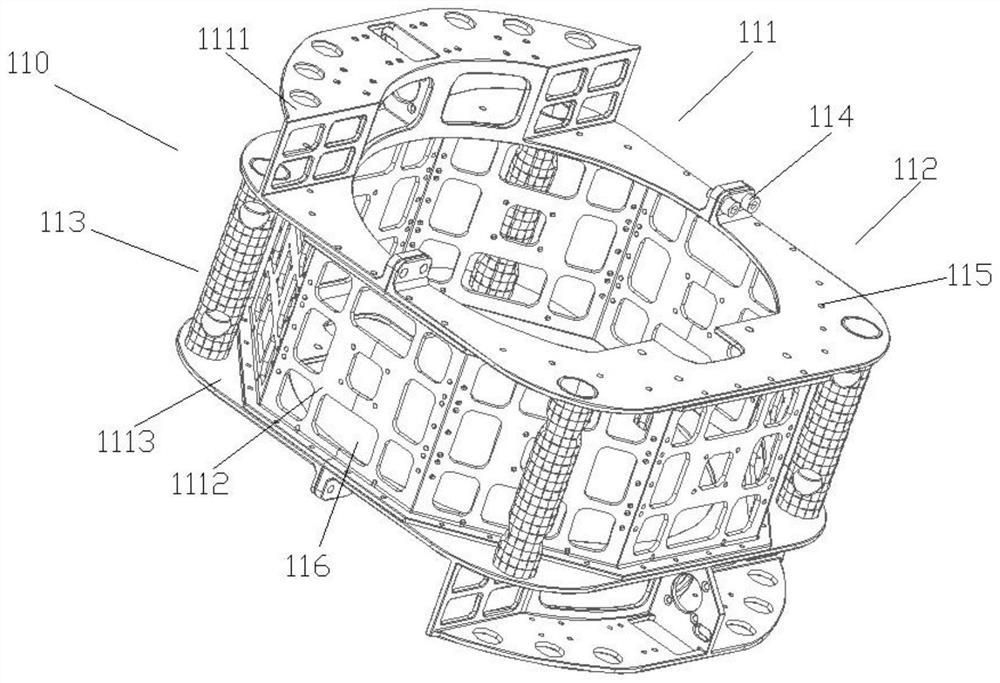

[0043] Please refer to the Figure 1 to Figure 9 , a cable climbing robot involved in the embodiment of the present application adopts a split structure, including a climbing precursor and a detection body, which are used to cooperate to realize advancing or retreating along the length direction of the cable 900 and to detect the cable 900 and maintenance. To be precise, the cable climbing robot of the present application is mainly used for climbing cables of cable-stayed bridges and suspension bridges. The cable climbing robot includes: a climbing precursor 100 and a detection body 200; wherein, the climbing precursor 100 includes: a precursor frame 110, a duct propeller 120, a precurso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com