Self-resetting shearing type lead damper and working method thereof

A working method and shear-type technology, applied in building types, building components, shock-proof, etc., can solve the problems of difficult replacement, limited energy consumption of shape memory alloy coils, and inability to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the method of the present invention is described in further detail. It should be noted that the protection scope of the present invention shall include but not be limited to the technical content disclosed in this embodiment.

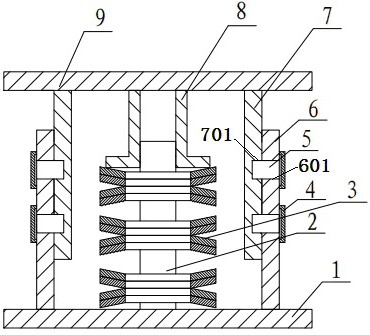

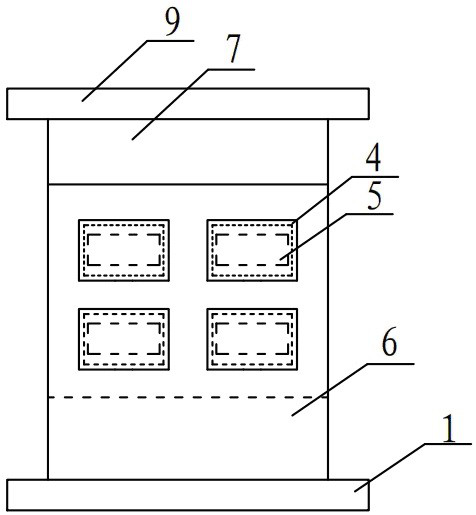

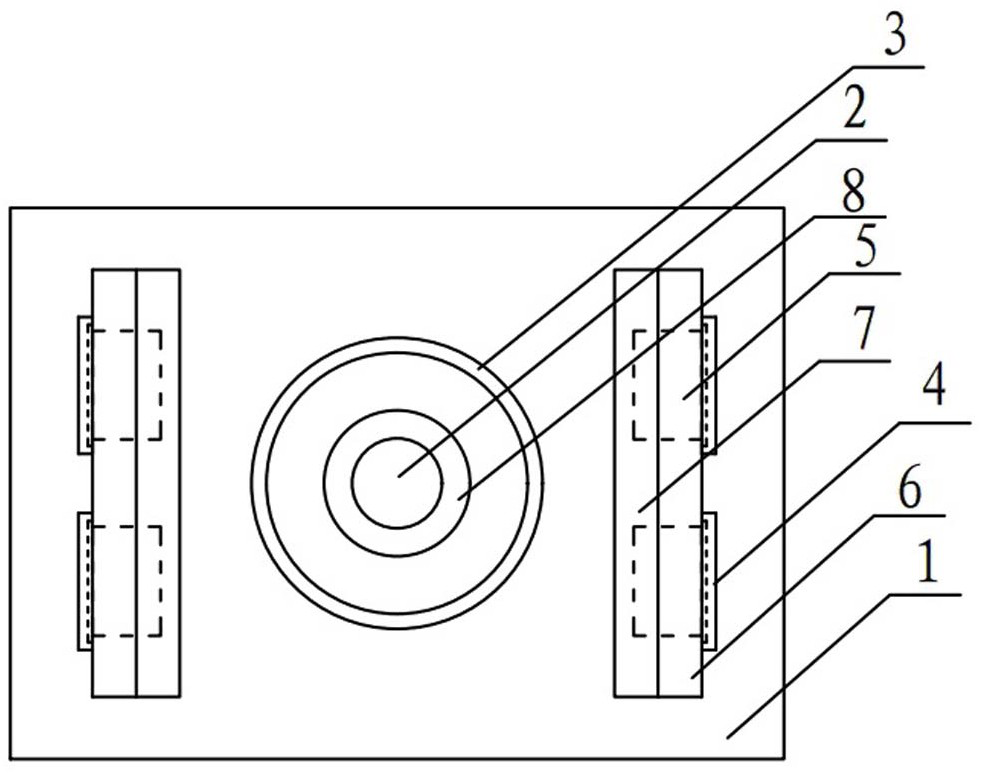

[0023] The self-resetting shear type lead damper of the present invention includes a bottom plate 1 and a top plate 9 which are arranged oppositely in the vertical direction. The lower surface of 9 is vertically provided with the second guide plate 7 that is close to the first guide plate, the first guide plate and the second guide plate are vertically staggered, and at least one guide plate is provided on the first guide plate 6. The first slot 601 is provided with a second slot 701 at a position corresponding to the first slot on the second guide plate 7, and a metal block 5 is embedded in the first slot and the second slot, and the bottom plate The upper surface of 1 is located between the two first guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com