Loading type waveguide optical modulator

A technology of modulator and waveguide light, which is applied in optics, instruments, optical components, etc., to achieve the effect of high modulation sensitivity and large modulation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

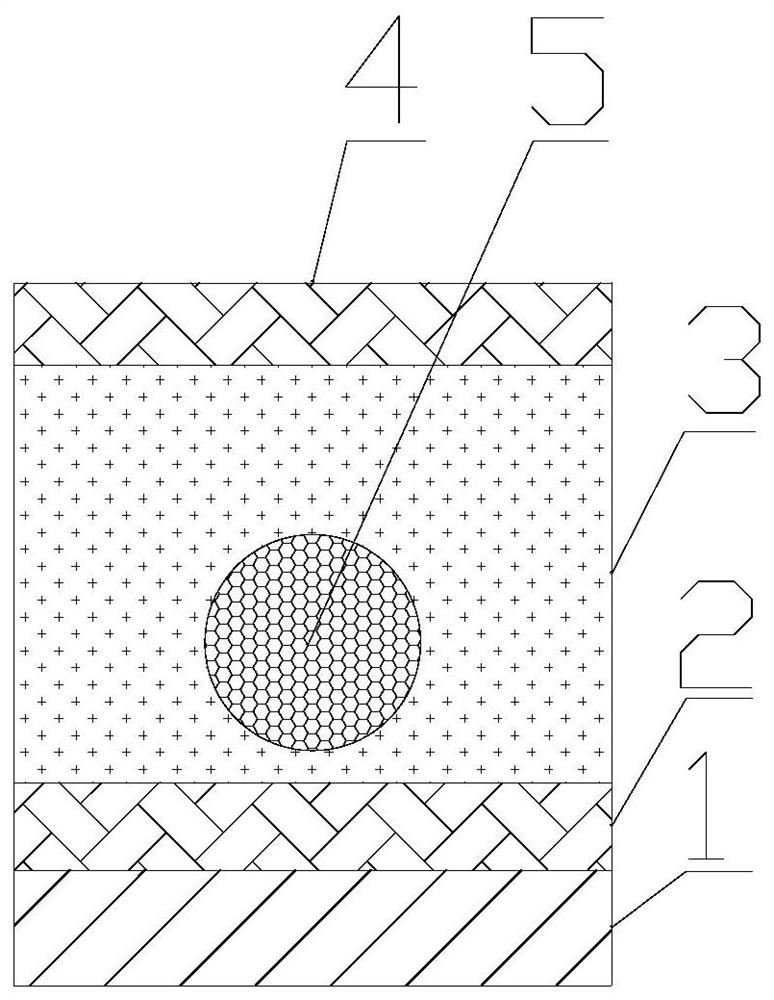

Embodiment 1

[0021] The invention provides a loaded waveguide light modulator. like figure 1 As shown, the optical modulator includes a substrate 1 , a first metal layer 2 , an electrostrictive material layer 3 , a second metal layer 4 , and a waveguide 5 . The material of the substrate 1 can be silicon or silicon dioxide. The material of the substrate 1 can also be other materials to facilitate the integration of the light modulator with other systems. The waveguide 5 is in the shape of a straight line, figure 1 The middle is the cross section of the waveguide 5 . The first metal layer 2 is placed on the substrate 1 . At the interface between the first metal layer 2 and the electrostrictive material layer 3, the first metal layer 2 is a plane. The material of the first metal layer 2 is gold. A layer 3 of electrostrictive material is placed on the first metal layer 2 . The electrostrictive material layer 3 can be any electrostrictive material, preferably, the material of the electro...

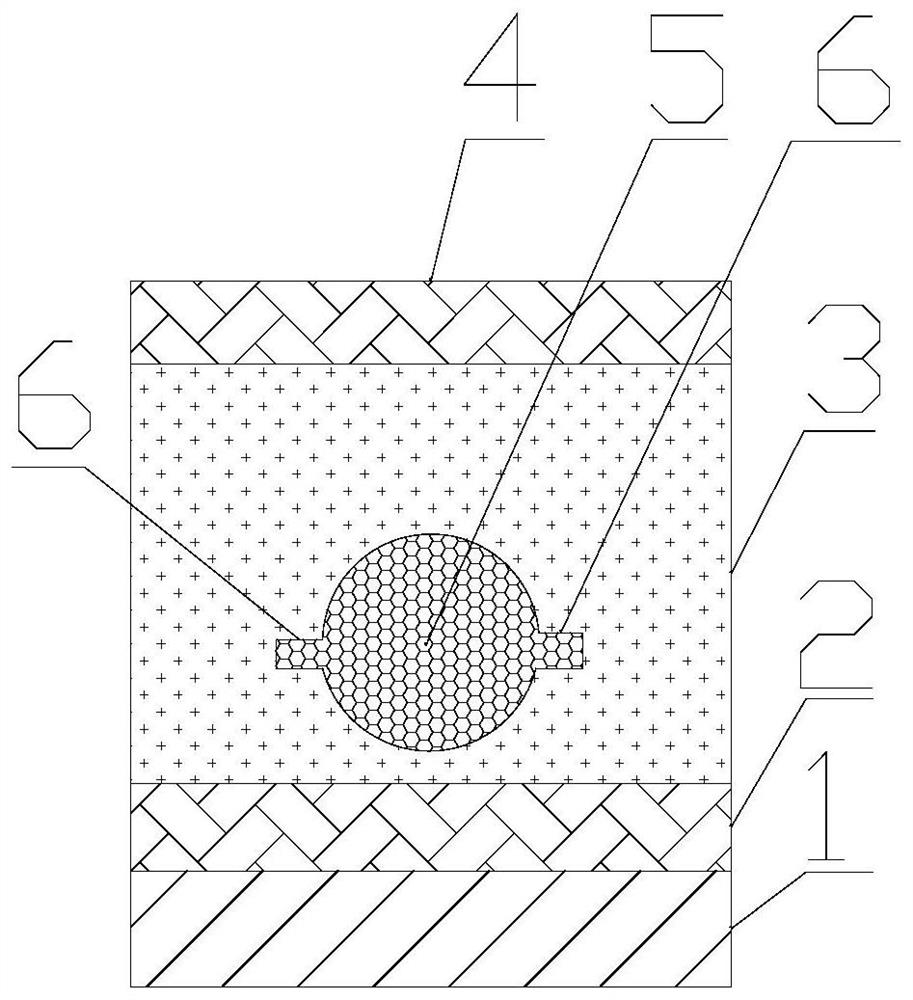

Embodiment 2

[0026] On the basis of Example 1, such as figure 2 As shown, a protruding portion 6 is also provided on the side of the waveguide portion 5 . The protruding part 6 is rectangular, and the long side of the rectangle is along the horizontal direction. The protruding part 6 makes the waveguide part 5 subjected to more effects of the electrostrictive material layer 3 to generate more deformation and change the propagation characteristics of the loaded waveguide more. For example, when the electrostrictive material layer 3 stretches, figure 2 The electrostrictive material under the middle protrusion will act on the protrusion 6, so that the waveguide receives more upward force, thereby generating more upward displacement.

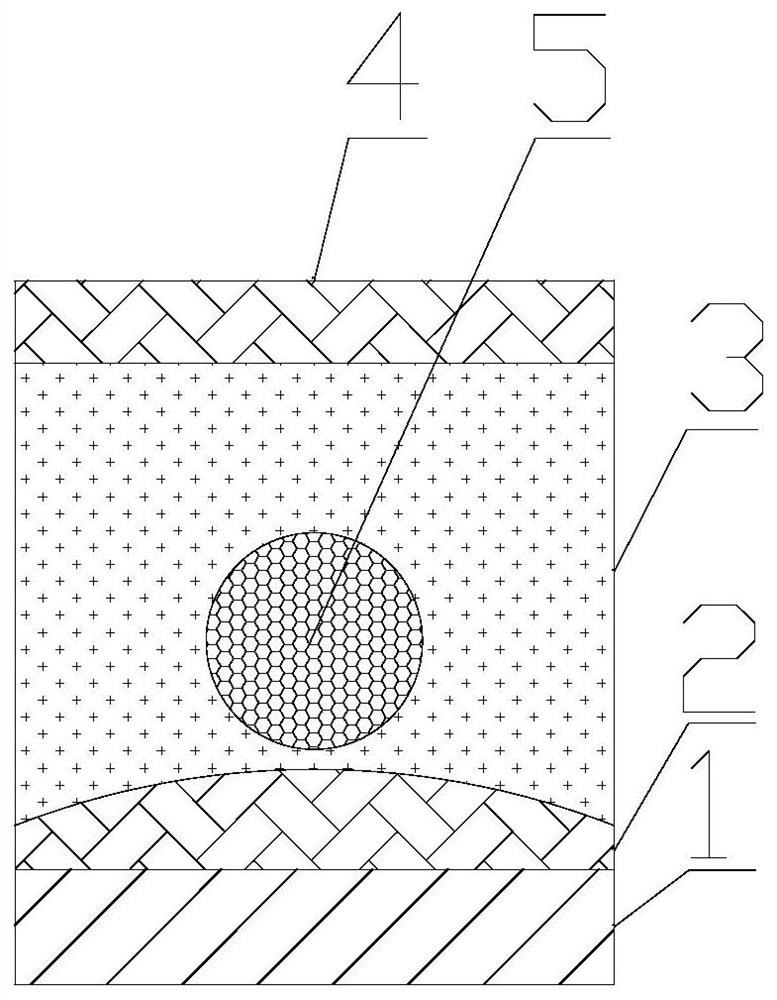

Embodiment 3

[0028] On the basis of Example 2, such as image 3 As shown, the interface between the first metal layer 2 and the electrostrictive material layer 3 has a convex arc surface, and the top of the arc surface is located directly below the waveguide part 5 . In this way, when a voltage is applied between the first metal layer 2 and the second metal layer 4, for the first metal layer 2, the charge is more concentrated on the top of the arc surface, and the top of the arc surface is in contact with the guided wave. The distance between the parts 5 is smaller, so that more charges of opposite sign are induced on the waveguide part 5 . Under the combined action of the charges on the arc surface of the first metal layer 2 and the charges of opposite sign on the waveguide 5, a stronger electric field is formed between the arc surface of the first metal layer 2 and the waveguide 5, and these electric fields make The electrostrictive material in between produces more deformation, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com