Ultra-sensitive strong laser power detection structure

A technology of strong laser and high power, which is applied in the field of detection structure of ultra-sensitive strong laser power, can solve the problems of inability to realize ultra-sensitive detection of strong laser and cannot directly apply strong laser, etc., and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

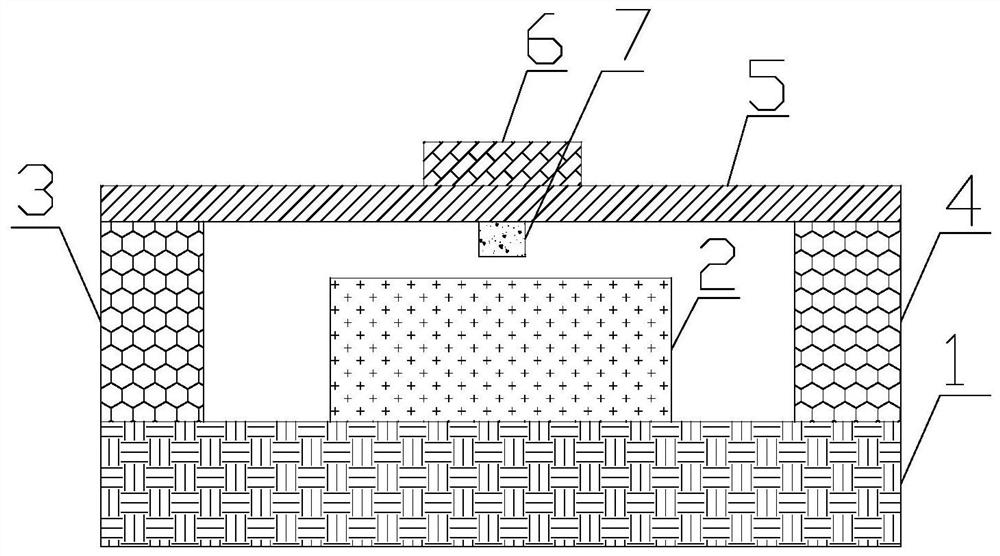

[0021] The invention provides an ultra-sensitive strong laser power detection structure. like figure 1 As shown, the ultra-sensitive strong laser power detection structure includes: a substrate 1 , a waveguide 2 , a first support portion 3 , a second support portion 4 , an elastic deformation layer 5 , a reflective layer 6 , and a sensing portion 7 . The waveguide 2 is placed on the substrate 1, and the material of the waveguide 2 is silicon dioxide. The material of the substrate 1 is magnesium fluoride. The first supporting part 3 and the second supporting part 4 are respectively placed on two sides of the section of the waveguide 2 . The first support part 3 and the second support part 4 are made of non-elastic material, and the materials of the first support part 3 and the second support part 4 are not limited here. The height of the first support part 3 and the second support part 4 is greater than that of the waveguide 2 , and the elastic deformation layer 5 is fixed o...

Embodiment 2

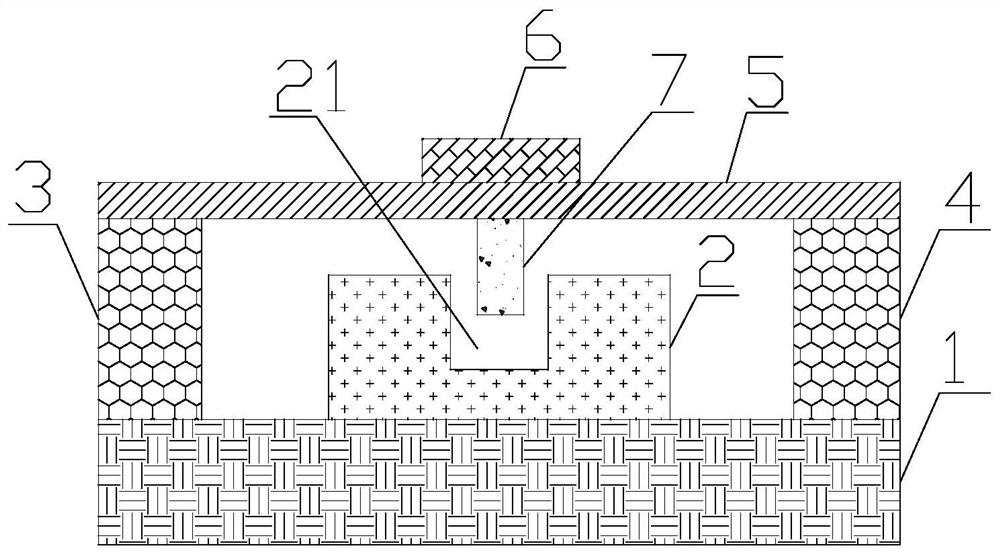

[0024] On the basis of Example 1, such as figure 2 As shown, the waveguide 2 is provided with a groove 21 , the sensing part 7 is placed above the groove 21 , and the width of the sensing part 7 is smaller than the width of the groove 21 . The material of the waveguide 2 is silicon dioxide. The material of the sensing part 7 is noble metal. When the elastic deformation layer 5 is deformed, the sensing part 7 can extend into the groove 21 . In this way, the sensing part 7 can change the propagation characteristics of the waveguide 2 more, thereby improving the sensitivity of detecting strong laser power. In this embodiment, the material of the waveguide 2 is silica, which is the same as the core material of an ordinary optical fiber, which is beneficial to reduce costs.

Embodiment 3

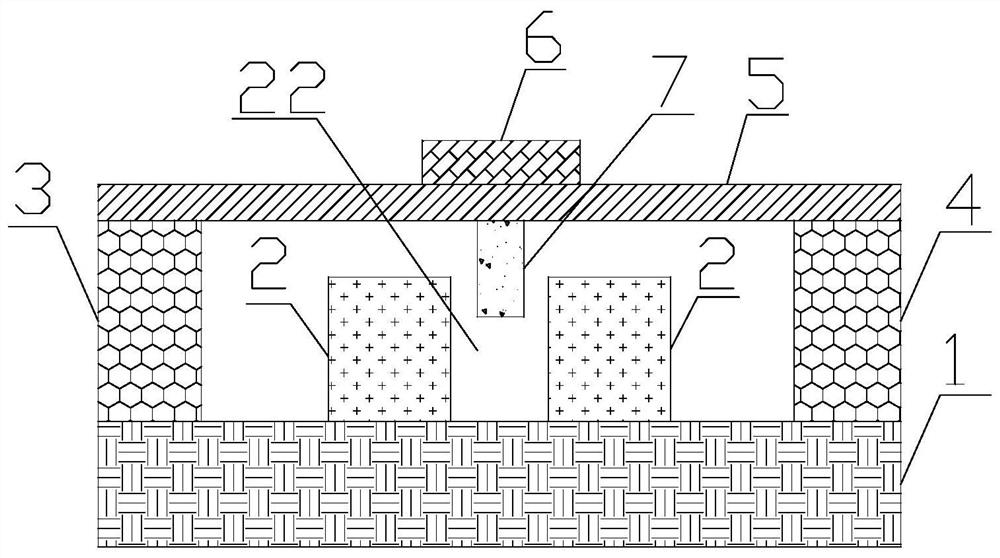

[0026] On the basis of Example 1, such as image 3 As shown, there is a slot 22 inside the waveguide 2 , the sensing part 7 is placed above the slot 22 , and the width of the sensing part 7 is smaller than the width of the slot 22 . The material of the waveguide 2 is silicon dioxide. The material of the sensing part 7 is noble metal. In this way, the sensing part 7 can penetrate more deeply into the waveguide 2, thereby changing the propagation characteristics of the waveguide 2 more, thereby improving the sensitivity of detecting strong laser power.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com