Electric control tunable porous terahertz band gap optical fiber

An optical fiber and electronic control technology, applied in the direction of cladding optical fiber, light guide, optics, etc., can solve the application limitations of optoelectronic technology and microwave technology, etc., and achieve the effect of low transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

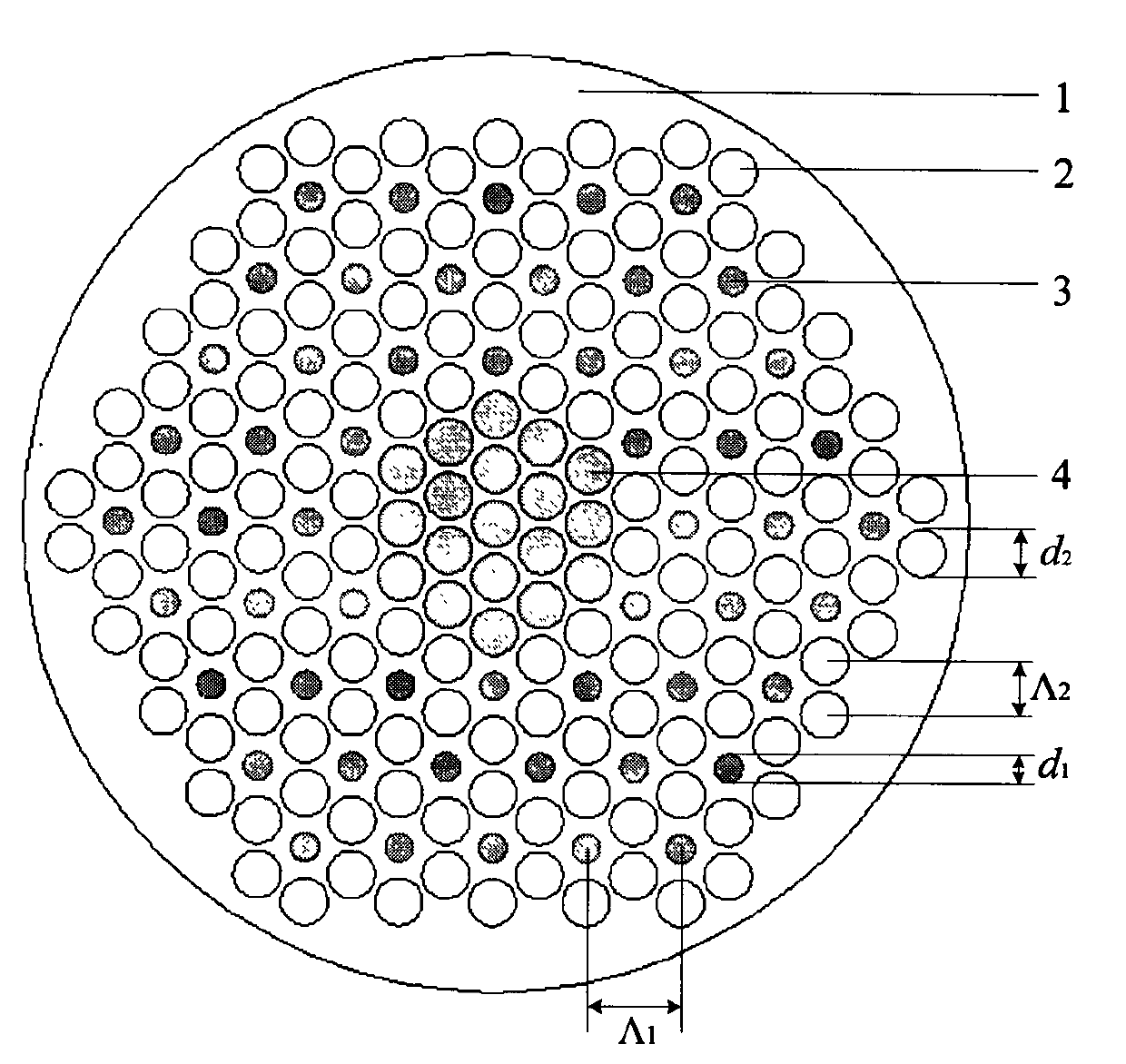

[0016] Such as figure 1 As shown, the optical fiber is composed of a cladding composed of a base material 1 and composite air holes 2 and 3, and a porous core 4, which is composed of a porous structure formed by 19 air holes. Spacing Λ of air holes arranged in a triangular lattice in the cladding 1 =295μm, air hole diameter d 1 =0.33Λ 1 , the spacing of the air holes arranged in a honeycomb lattice Air hole diameter d 2 =0.55Λ 1 . The spacing and diameter of the air holes in the fiber core are consistent with those of the air holes 2 . The air hole 3 is filled with nematic liquid crystal 5CB. When filling the liquid crystal, the surface of the air hole is pre-treated, and some active reagents are injected to anchor the direction of the liquid crystal molecules to be parallel to the optical axis of the fiber.

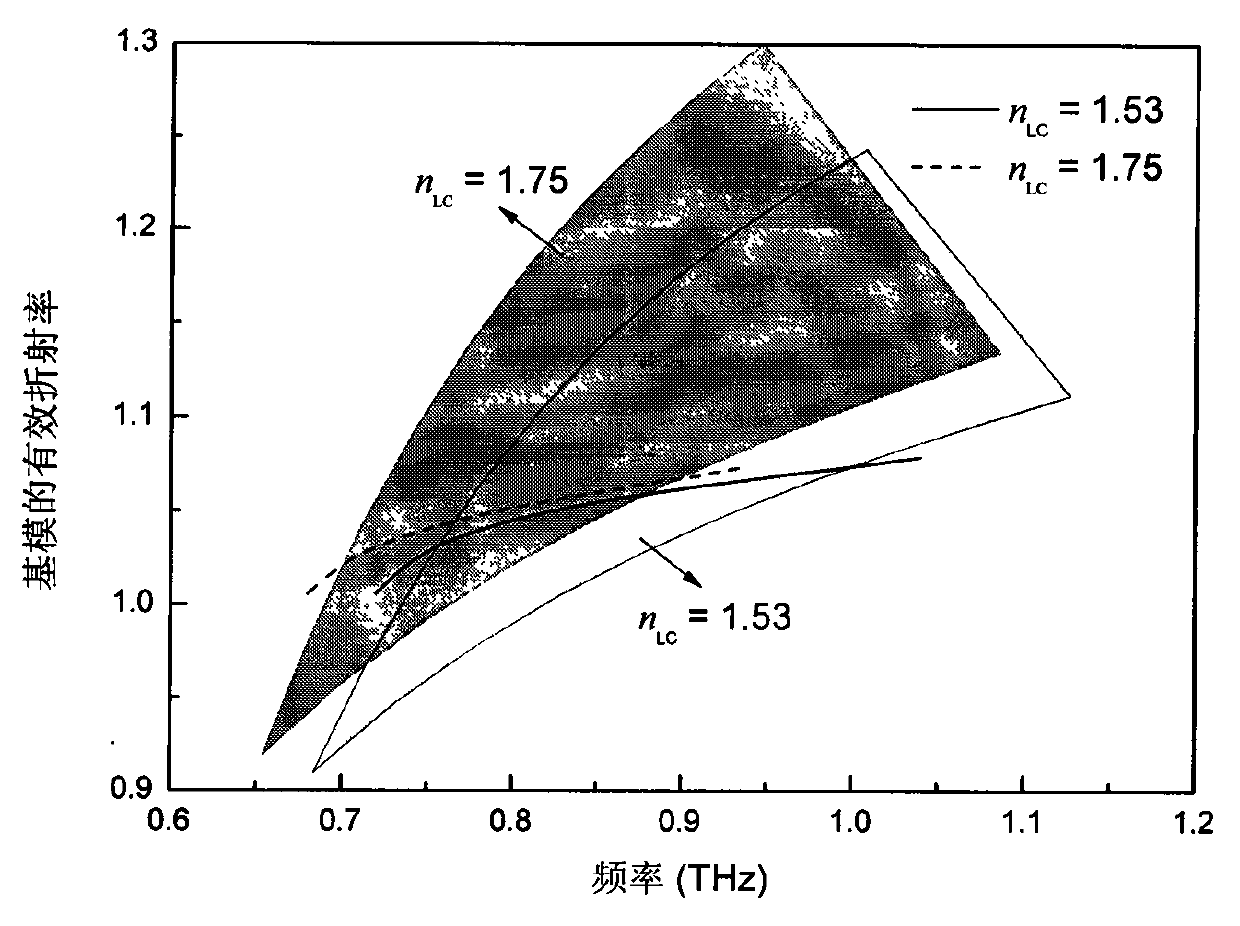

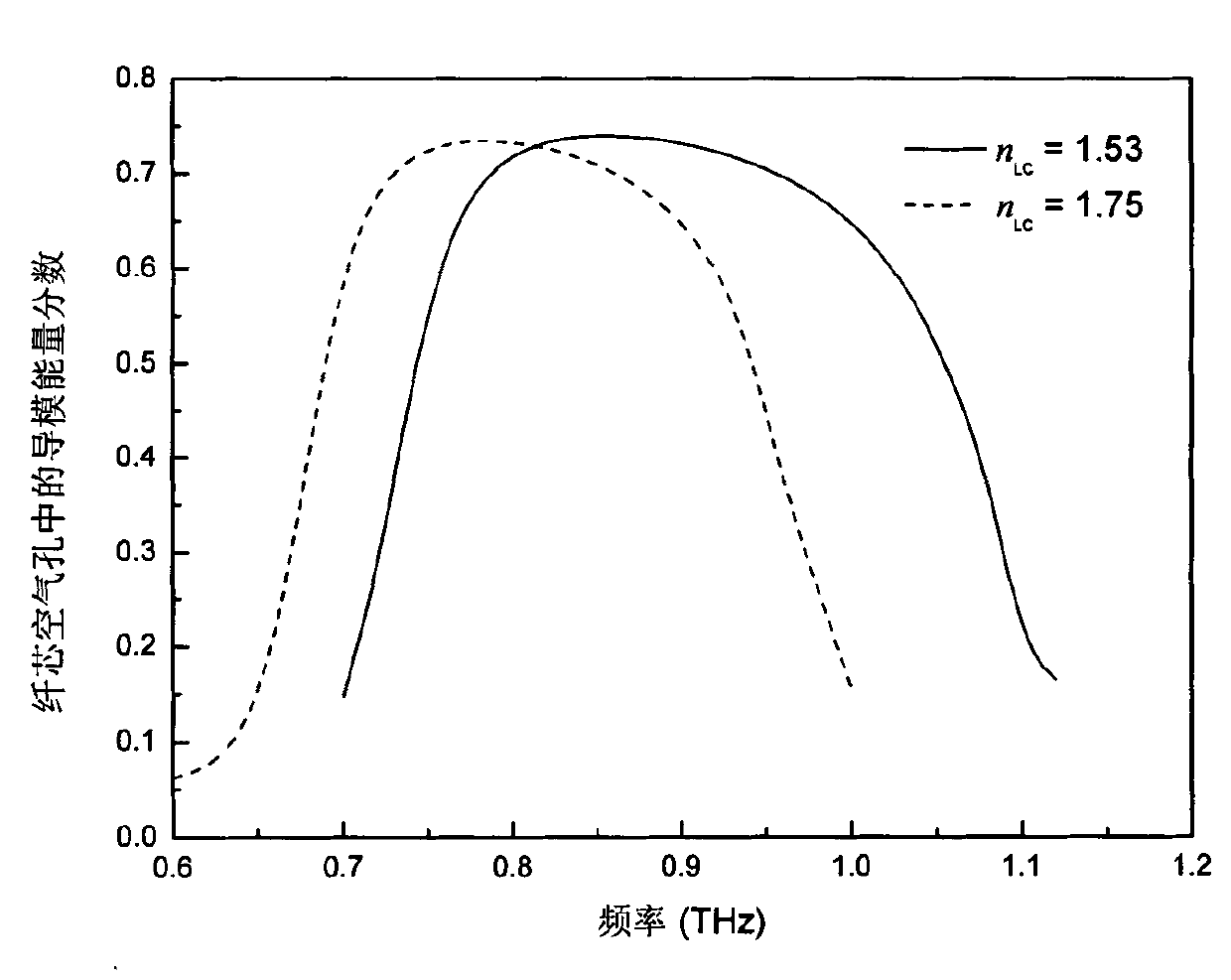

[0017] The base material of the optical fiber is high-density polyethylene with a refractive index of 1.534. Air has a refractive index of 1. The liquid crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com