Optical fiber liquid viscosity coefficient measuring device

A technology of viscosity coefficient and measuring device, which is applied in the direction of measuring device, indirect flow characteristic measurement, flow characteristic, etc., can solve the problem of low accuracy, and achieve the effect of high measurement accuracy and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

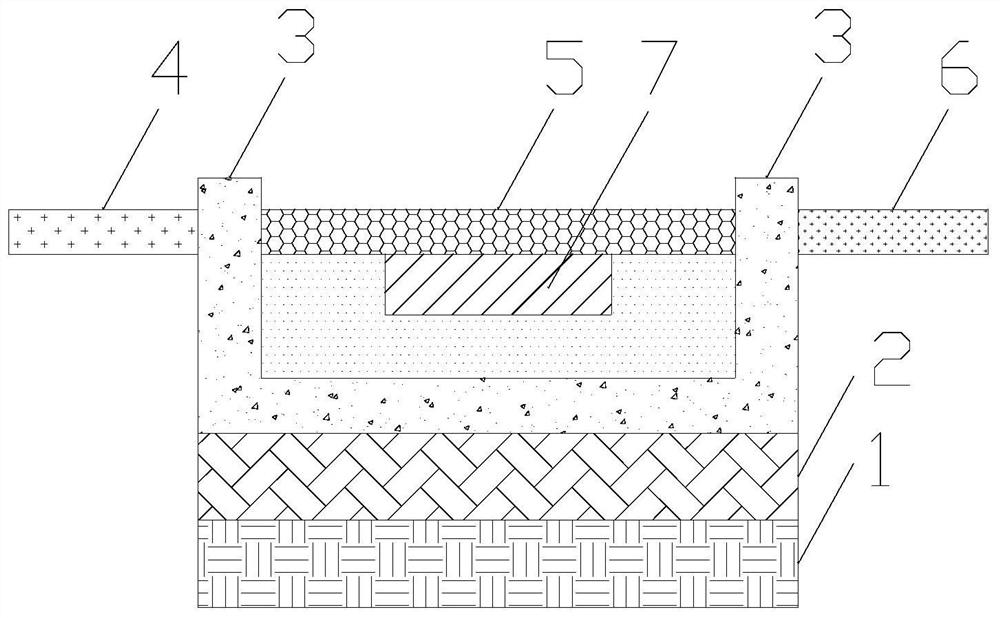

[0021] The invention provides an optical fiber liquid viscosity coefficient measuring device. Such as figure 1 As shown, the optical fiber liquid viscosity measurement device includes a base 1 , a vibration source 2 , a square groove 3 , an optical fiber, and a force plate 7 . The vibration source 2 is placed on the base 1, the base 1 is used to support the vibration source 2, and the vibration source 2 is used to generate vibration. The direction of vibration can be horizontal or vertical. In order to improve the accuracy of the measurement, the change of the optical fiber propagation coefficient is measured in different vibration directions, and the viscosity coefficient of the liquid is deduced in each case, and then the average value is taken. The square tank 3 is placed on the vibration source 2, and under the action of the vibration source 2, the liquid in the square tank 3 vibrates. The core idea of the invention can also be realized when the groove is of general s...

Embodiment 2

[0025] On the basis of Embodiment 1, the diameter of the sensitive part 5 is smaller than the diameters of the incident part 4 and the outgoing part 6 . In this embodiment, the sensitive part 5 is not a grating fiber. Specifically, the coating layer of the sensitive part 5 is thinner than that of the incident part 4 and the outgoing part 6 , so that the diameter of the sensitive part 5 is smaller than the diameters of the incident part 4 and the outgoing part 6 . In this way, under the action of the force plate 7, the sensitive part 5 is more likely to be bent, thereby changing the transmission characteristics of the optical fiber more, thereby realizing a higher accuracy measurement of the viscosity coefficient of the liquid.

[0026] Furthermore, the core diameter of the sensitive part 5 is also smaller than the core diameters of the incident part 4 and the outgoing part 6 . In this way, when the sensitive part 5 bends, the propagation characteristics of the sensitive part ...

Embodiment 3

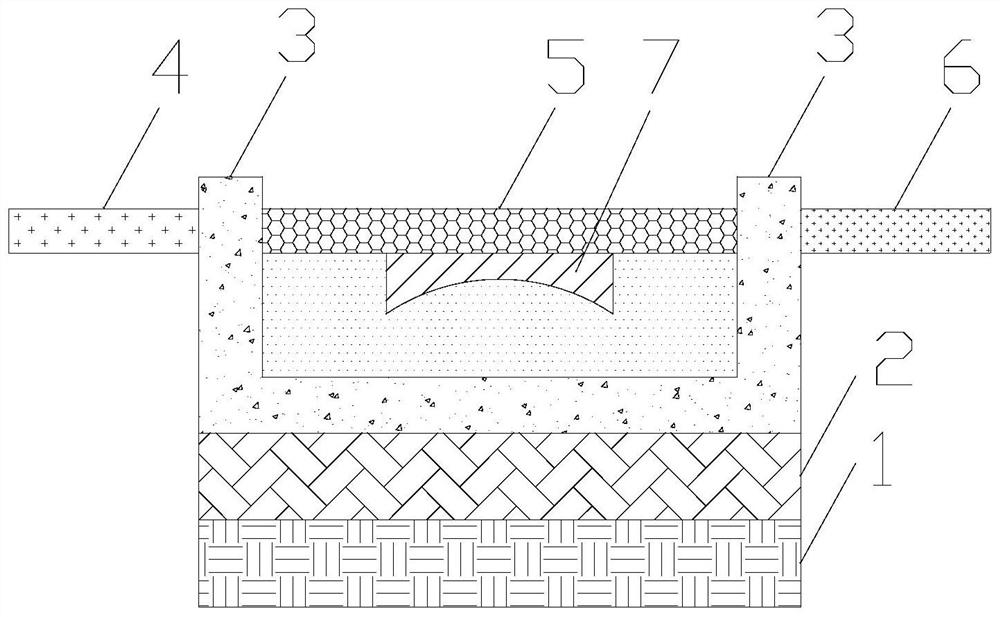

[0028] On the basis of Embodiment 1 or 2, the bottom surface of the force plate 7 is concave. That is to say, the surface of the force receiving plate 7 in contact with the liquid surface is concave. In this way, on the one hand, when the vibration source 2 vibrates in the vertical direction, the concave shape is more consistent with the shape of the wave crest, so that the liquid can have more effects on the force plate 7, so that the force plate 7 is sensitive to changes On the other hand, when the vibration source generates vibration in the horizontal direction, the area of action between the concave shape and the liquid is larger, so that the force generated by the liquid on the force plate 7 is greater, thus changing more Propagation characteristics of the sensitive part 5. Therefore, this embodiment can realize higher accuracy measurement of liquid viscosity coefficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com