High-sensitivity rotating speed detection device

A speed detection and sensitive technology, applied in the mechanical field, can solve the problems of increasing the cost of the detection device, achieve the effects of small force, good application prospects, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

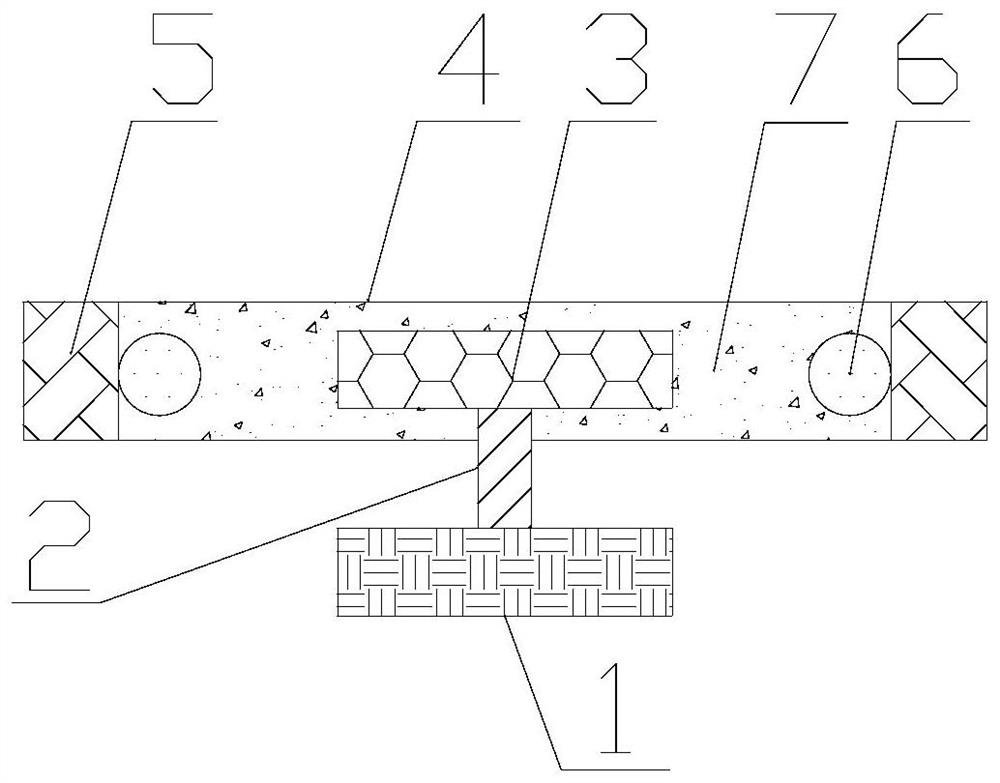

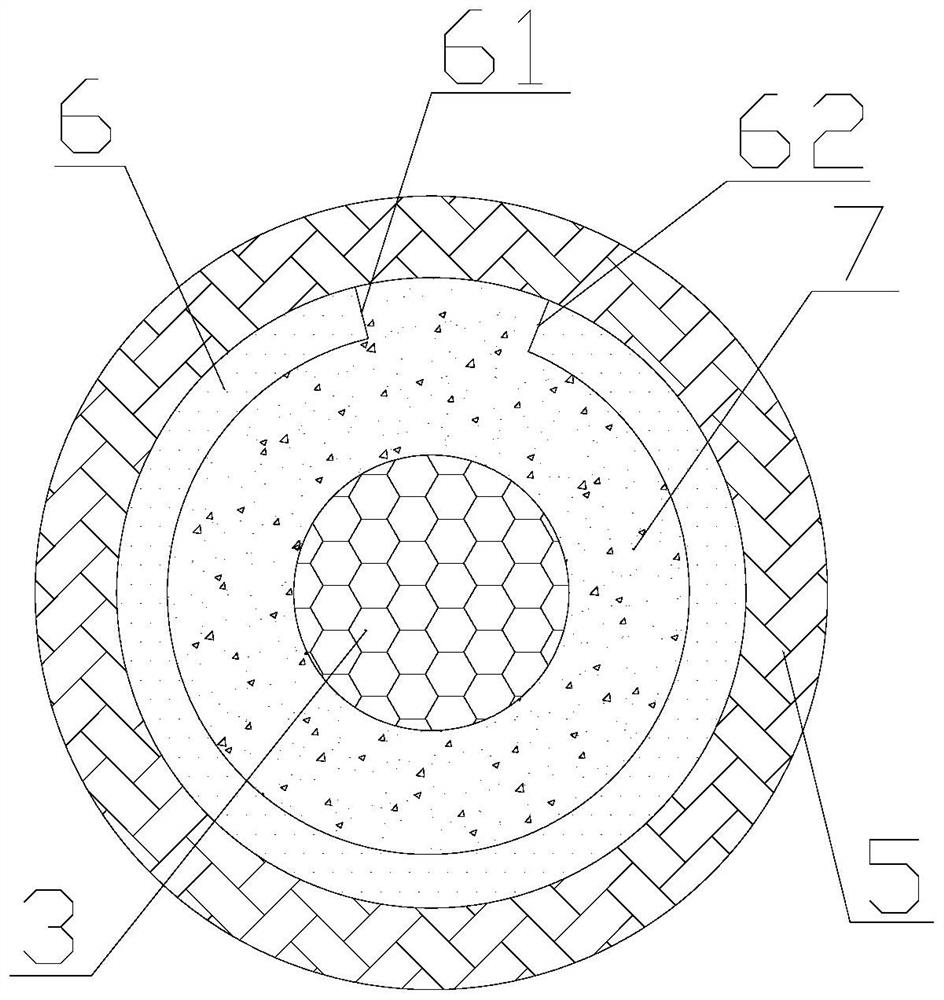

[0021] The invention provides a highly sensitive rotational speed detection device. Such as figure 1 and figure 2 As shown, the high-sensitivity speed detection device includes a fixed part 1 , a rotating shaft 2 , a rotating disk 3 , a sensor box 4 , an elastic layer 5 , an optical fiber 6 , and a fluid 7 . The material of the sensing box 4 is stainless steel. The material of the rotating shaft 2 is stainless steel or other solid materials, which is not specifically limited here. The rotating shaft 2 runs through the bottom surface of the sensing box 4 , one end of the rotating shaft 2 is fixedly connected to the fixed part 1 , and the other end of the rotating shaft 2 is fixedly connected to the rotating disk 3 in the sensing box 4 . The material of the rotating disk 3 is stainless steel. The cross section of the sensing box 4 is circular, and the cross section of the rotating disk 3 is circular. When rotating, the rotating disk 3 is not in contact with the sensor box ...

Embodiment 2

[0027] On the basis of Embodiment 1, the optical fiber 6 includes a grating optical fiber. That is to say, the optical fiber 6 contains at least one section of grating fiber. Under the action of the centrifugal force of the fluid 7, the grating fiber is elongated, so that the center wavelength of the grating fiber is red-shifted. The rotational speed is determined by measuring the movement of the center wavelength of the grating fiber. Furthermore, the optical fiber 6 includes two sections of grating optical fibers with different central wavelengths. In this way, when the optical fiber 6 is elongated by centrifugal force, the central wavelengths of the two sections of the grating optical fiber are moved. The rotational speed of the object to be measured can be obtained by the difference between the two center wavelengths, and the experimental data processing is simple.

Embodiment 3

[0029] On the basis of Embodiment 2, the edge of the rotating disk 3 is toothed, and the teeth are distributed around the rotating disk 3 . In this way, the interaction between the rotating disk 3 and the fluid 7 is enhanced, so that the fluid 7 rotates at a faster speed, generates greater centrifugal force, changes the optical fiber 6 to a greater extent, and improves the sensitivity of rotational speed detection. The rotating disk 3 does not have chirality, so that when the object to be measured rotates in the opposite direction, the present invention can also accurately measure the rotational speed. Furthermore, the length of the teeth is adjustable. When the object to be measured rotates fast, the teeth are short, and the force on the optical fiber 6 is small; when the object to be measured rotates slowly, the teeth are long, and the force on the optical fiber 6 is large. Therefore, the length of the tooth can be adjusted so that this embodiment has a wider measurement ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com