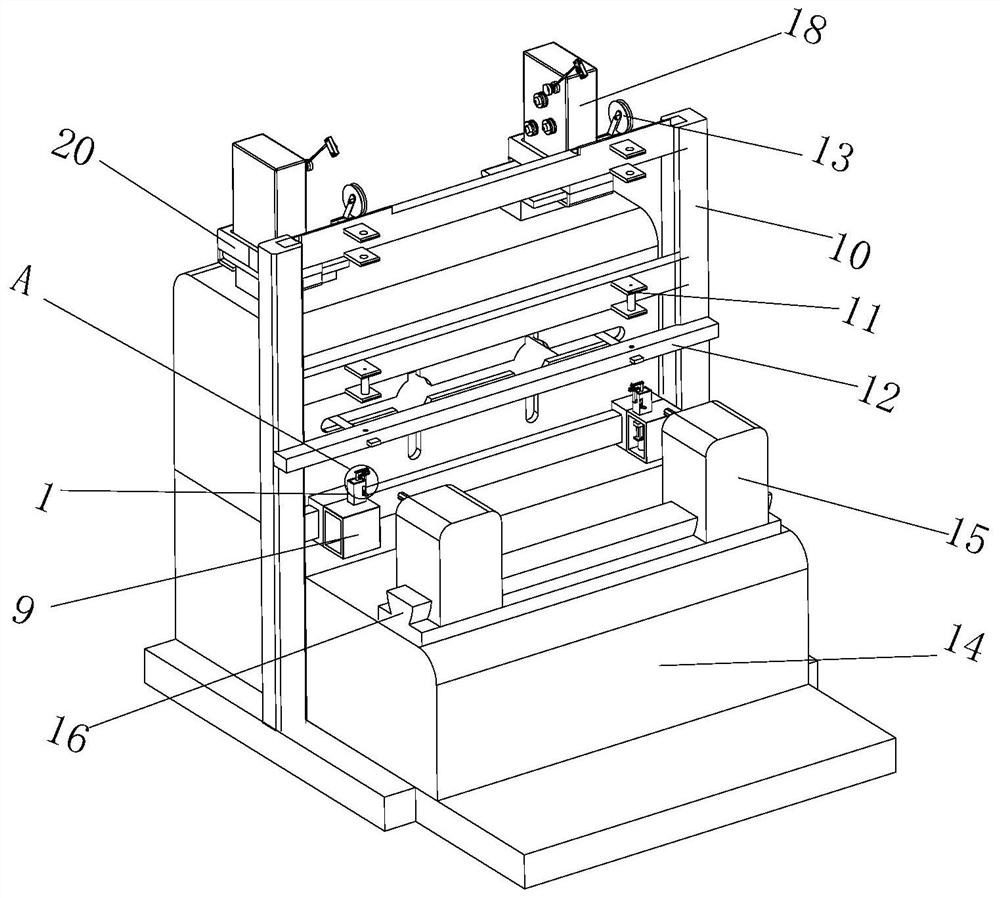

Enameled wire winding equipment for network transformer

A technology of network transformers and enameled wires, applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

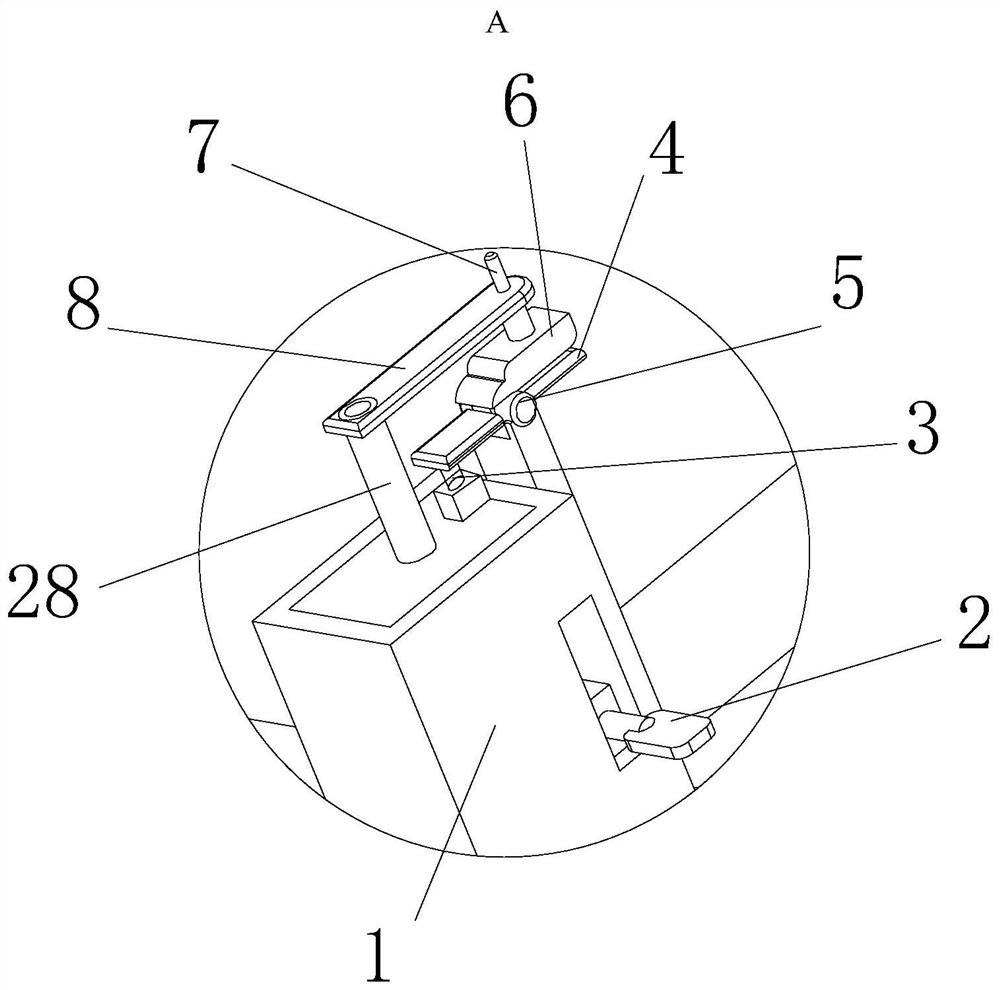

Examples

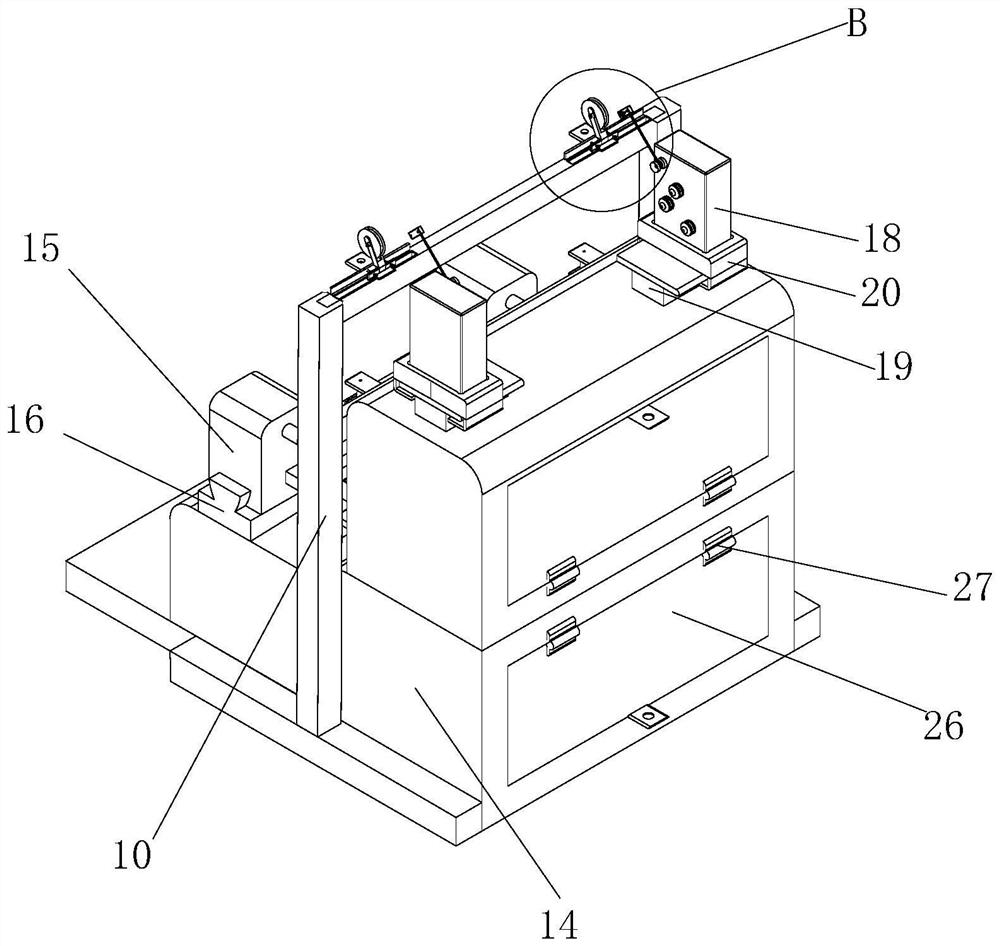

Embodiment approach

[0025] As an embodiment of the present invention, the wiring mechanism includes a second sliding guide rail 19, a sliding fixing frame 20, a groove 21, a fixing plate 22 and a pulley fixing frame 23; The outer side of the second sliding guide rail 19 is slidingly installed with a sliding fixing frame 20, and the inside of the sliding fixing frame 20 is provided with a connector 18, and the connector 18 and the sliding fixing frame 20 adopt clearance fit, and the connector 18 is positioned at the top of the second sliding guide rail 19 , and is in contact with the second sliding guide rail 19, the bottom end of the sliding fixing frame 20 is penetrated with a second fastening screw 29, and the sliding fixing frame 20 and the second fastening screw 29 are threadedly connected, and the top of the supporting frame 10 is The side is provided with groove 21 and fixed plate 22, and the top of groove 21 is equipped with pulley fixed frame 23, and pulley fixed frame 23 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com