Automatic turnover and combination device

A technology that automatically flips and rotates components. It is used in transportation and packaging, conveyor objects, electrical components, etc., and can solve problems such as affecting the quality of the welding process, low production efficiency, and difficulty in ensuring the accuracy, stability and consistency of lamination. , to achieve the effect of good operation timeliness, stable operation and good working environment adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

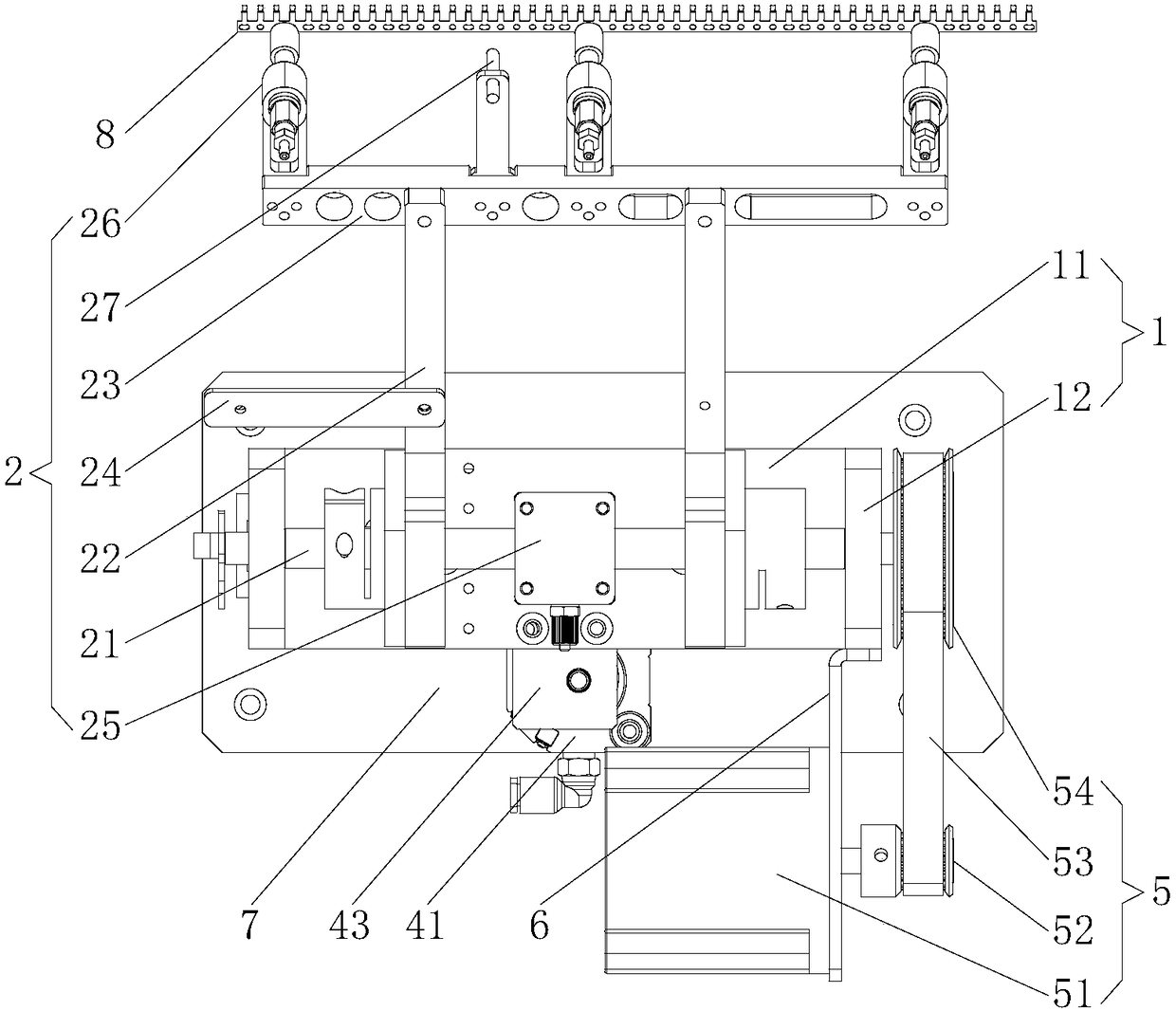

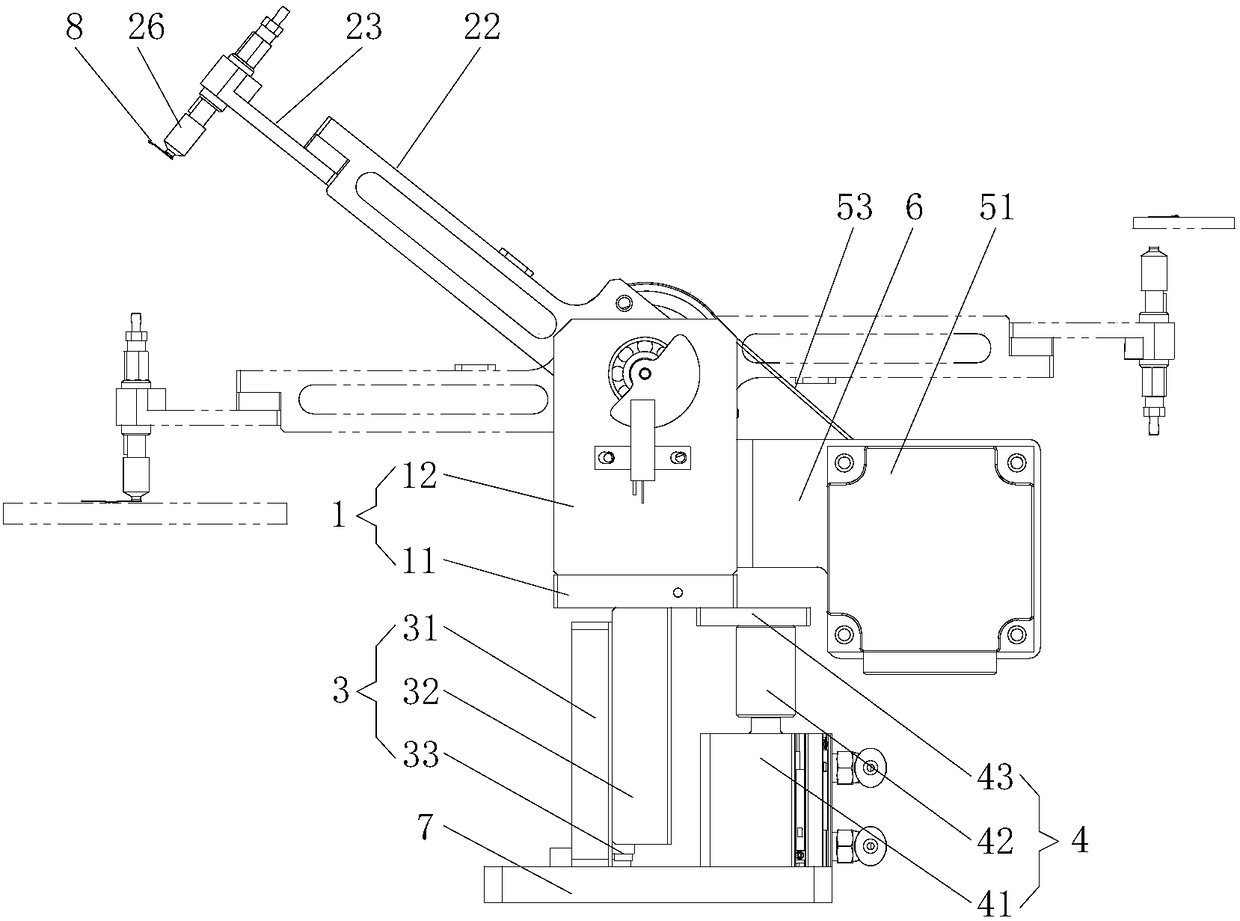

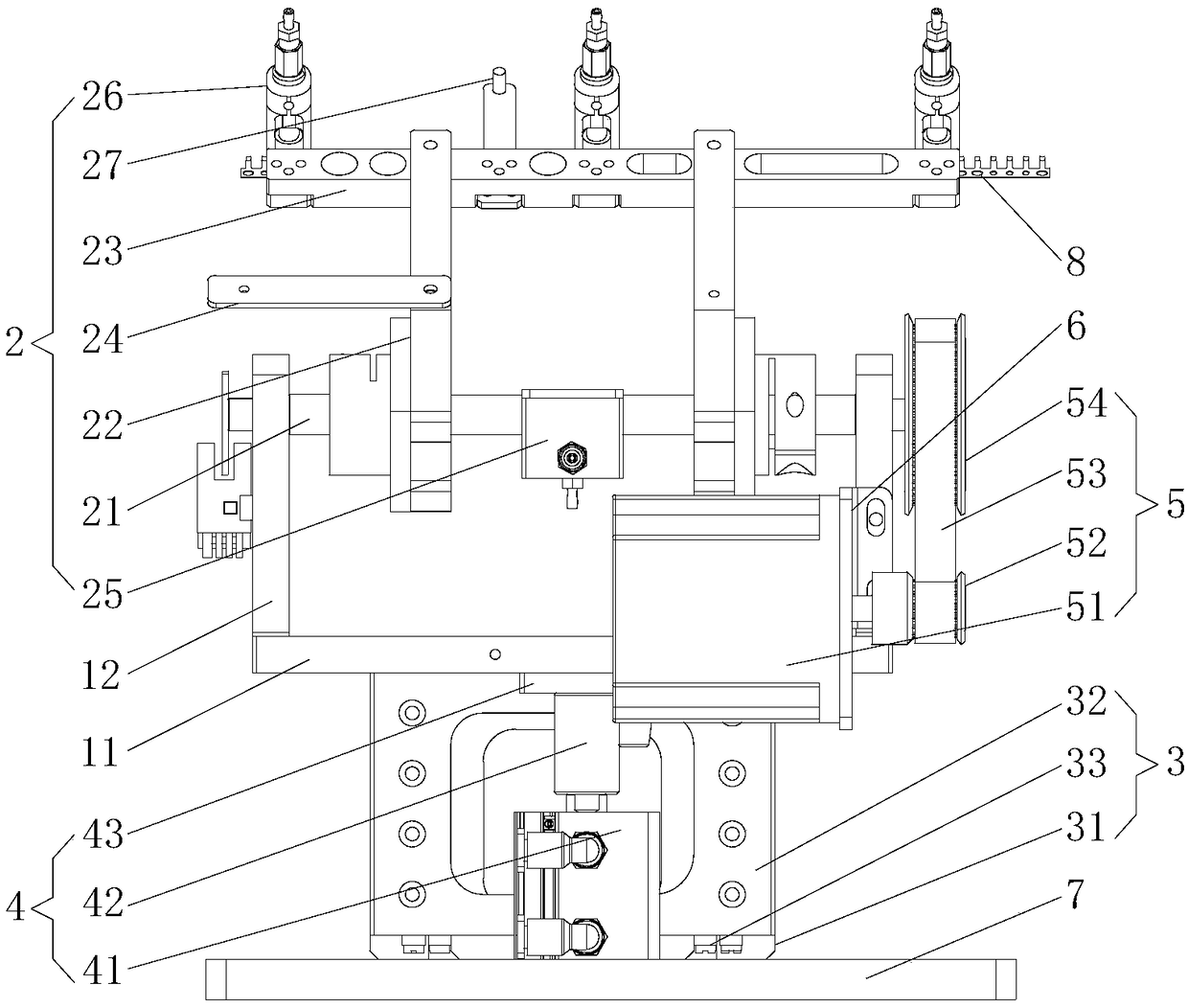

[0024] Such as Figure 1 to Figure 3 As shown, an automatic flipping device of this embodiment has a lifting bracket 1, a rotating member 2, a rotating member driving mechanism 5, a lifting bracket guiding mechanism 3, a lifting bracket height adjustment mechanism 4 and a base 7; the lifting bracket guiding mechanism 3 and the height adjustment mechanism 4 of the lifting bracket are all fixed on the base 7, and the lifting bracket 1 is arranged on the guiding mechanism 3 of the lifting bracket.

[0025] Such as figure 1 and image 3 As shown, the lifting support 1 includes a base plate 11 and a vertical plate 12, the vertical plates 12 are two pieces and are respectively located at the two ends of the base plate 11, and the two vertical plates 12 and the base plate 11 form a groove structure.

[0026] Such as Figure 1 to Figure 3 As shown, the rotating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com