An automatic production equipment for smart sockets

A technology of automatic production and intelligent socket, which is applied in the manufacture of contact parts, etc., can solve the problems of restricting production efficiency, inconvenient unloading and transfer of workpieces, etc., and achieve the effect of strong overall coordination, high work efficiency and improved transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

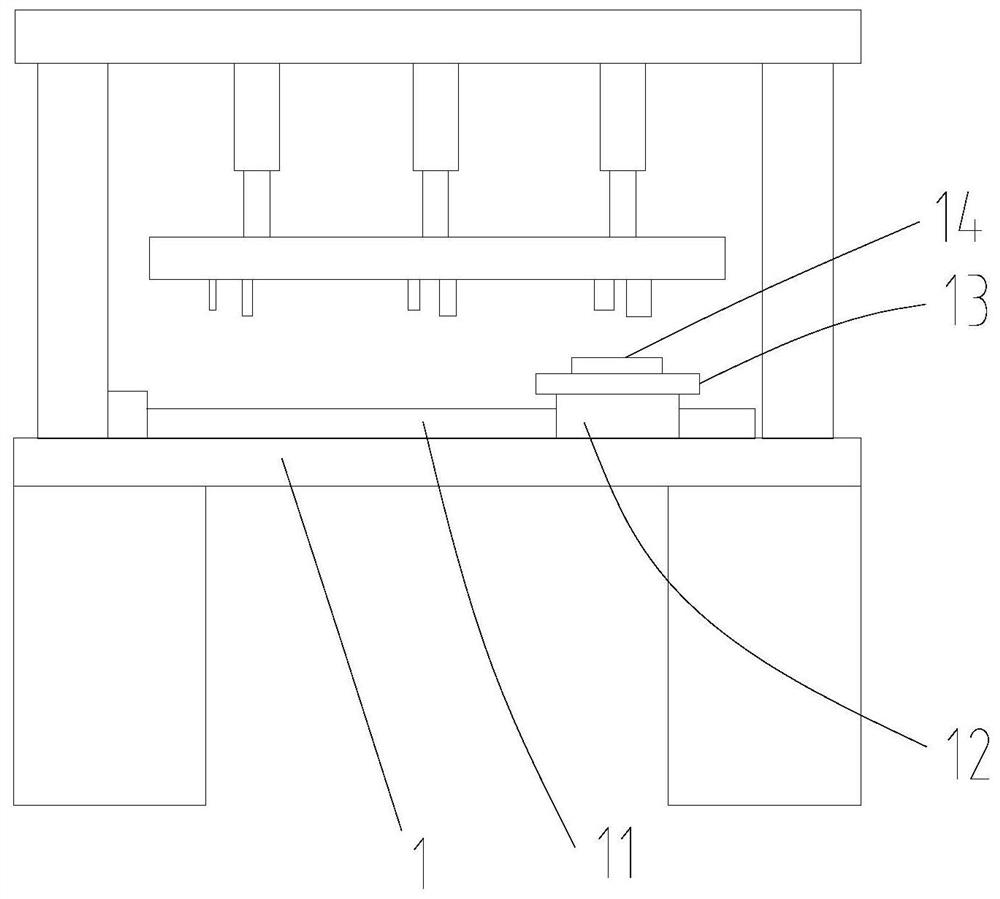

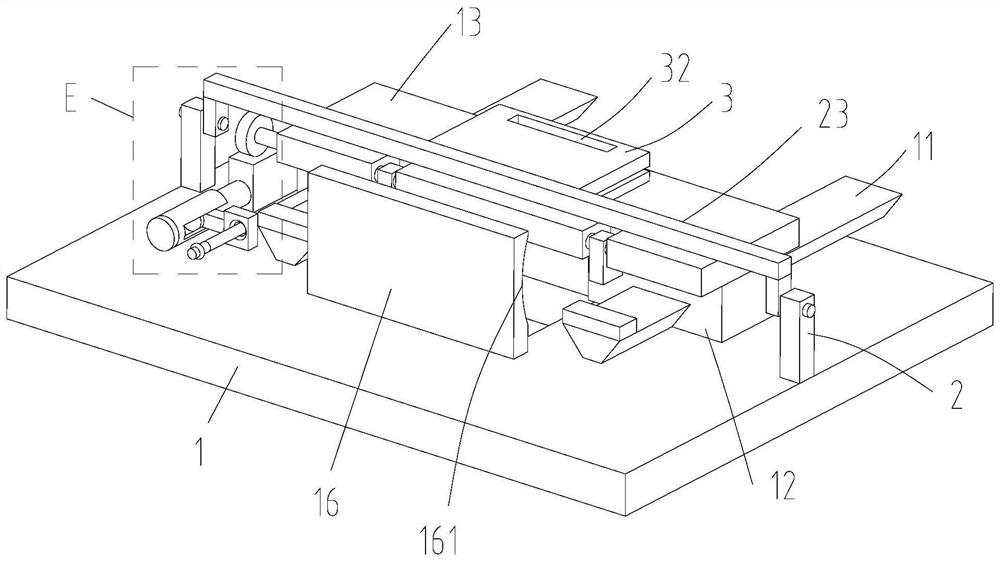

[0026] As an embodiment of the present invention, the side of the supporting plate 3 close to the lower module 14 is fixedly connected to the baffle plate 31, and the baffle plate 31 is set corresponding to one end of the lower module 14, so as to prevent the workpiece from being caught between the supporting plate 3 of the lower module 14 when turning over. drop.

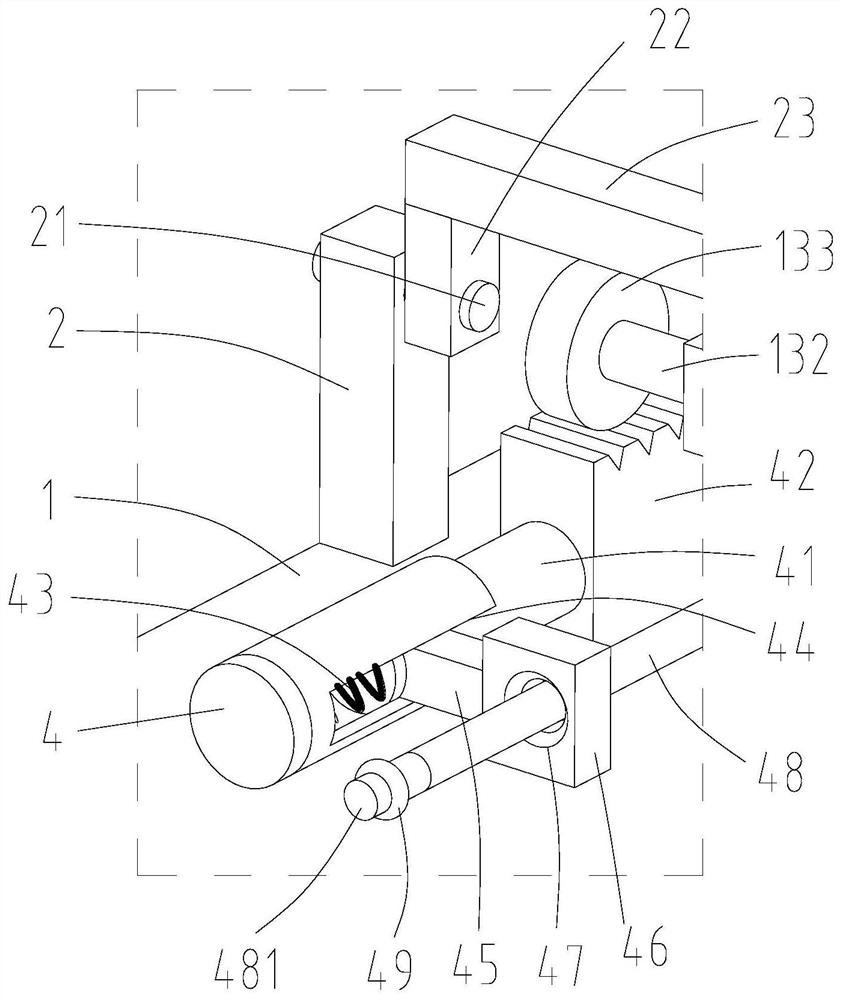

[0027] As an embodiment of the present invention, the end of the push rod 48 is coaxially fixedly connected to the cylinder 481 by bolts, the outer circle of the cylinder 481 is provided with an annular groove, and the rubber ring 49 is installed in the annular groove. The cylinder 481 can be replaced, and the rebound force that the support spring 43 can provide corresponds to the quality setting of the lower module 14 and the supporting plate 3, and the wear of the rubber ring 49 is also corresponding. The wear speed of the rubber ring 49 affects the operation of the device, and then needs It is convenient to repl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com