Heating film and preparation method thereof

A technology of heating film and fiber film, applied in the field of heating film and its preparation, can solve the problems of energy waste, uneven heat of electric heating tubes, etc., and achieve the effect of simple and reasonable structure design, good application prospect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

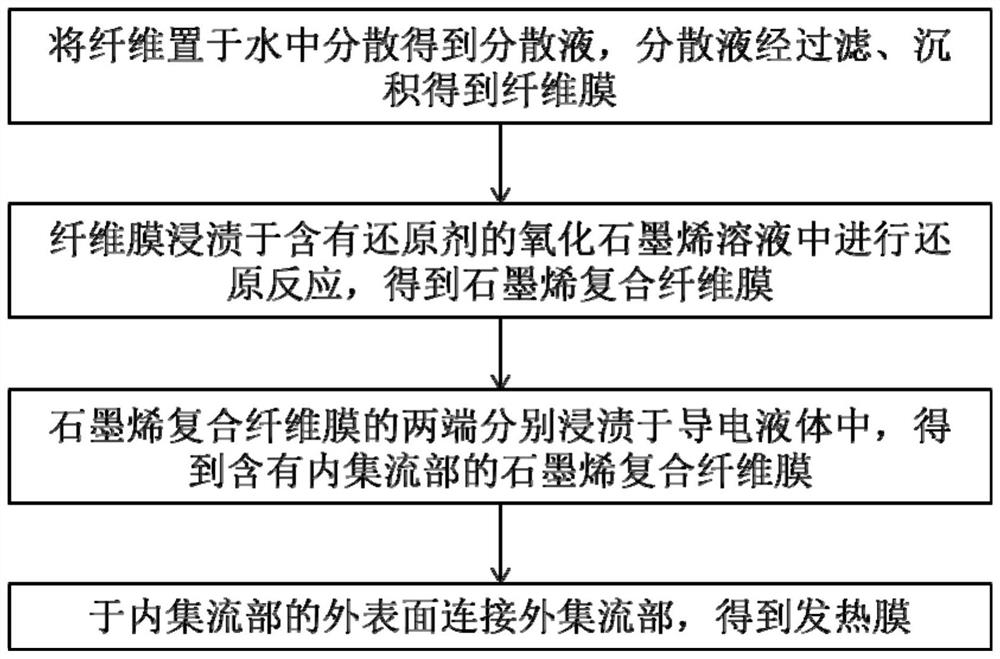

Method used

Image

Examples

Embodiment Construction

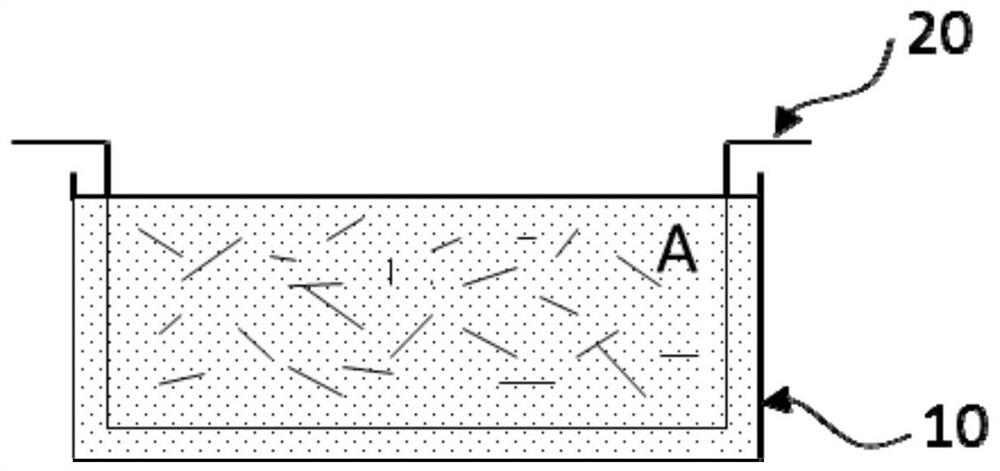

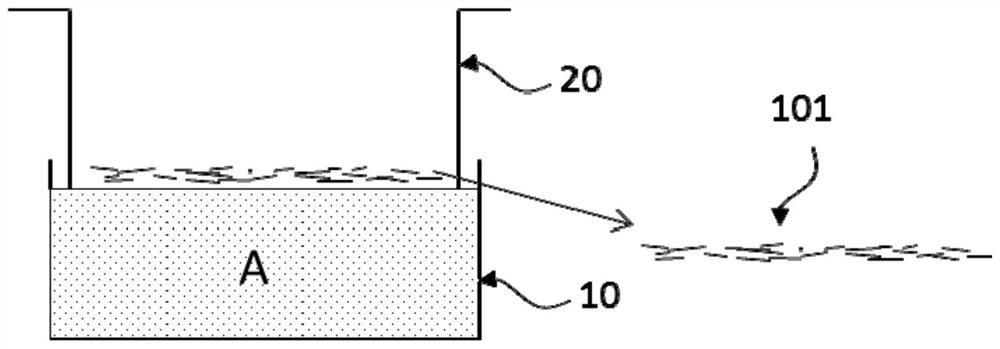

[0033] Typical embodiments that embody the features and advantages of the present disclosure will be described in detail in the following description. It should be understood that the present disclosure can have various changes in different embodiments without departing from the scope of the present disclosure, and that the description and drawings therein are illustrative in nature and not intended to limit the present disclosure. public.

[0034] In the following description of various exemplary embodiments of the present disclosure, reference is made to the accompanying drawings, which form a part hereof, and in which are shown, by way of example, various exemplary structures, systems, which may implement aspects of the present disclosure and steps. It is to be understood that other specific arrangements of components, structures, exemplary devices, systems and steps may be utilized and structural and functional modifications may be made without departing from the scope of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature tolerance | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com