A milling device for fine processing of Trichosanthes

A technology for grinding powder and melon, which is applied in the field of grinding devices for finishing melon, can solve the problems of manpower consumption and low efficiency, and achieve the effects of improving production efficiency, convenient conversion and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

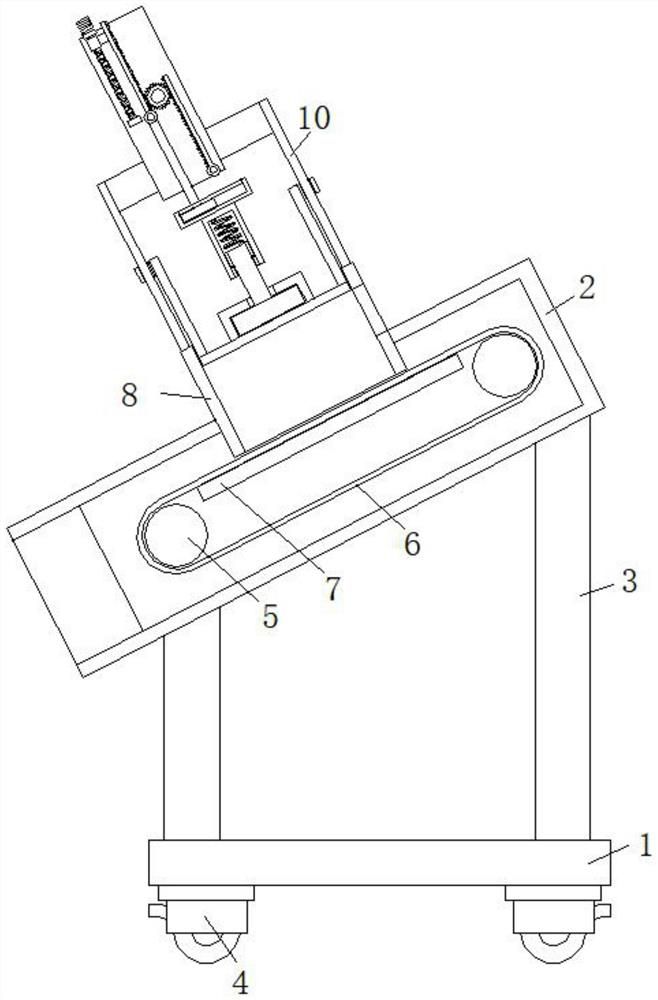

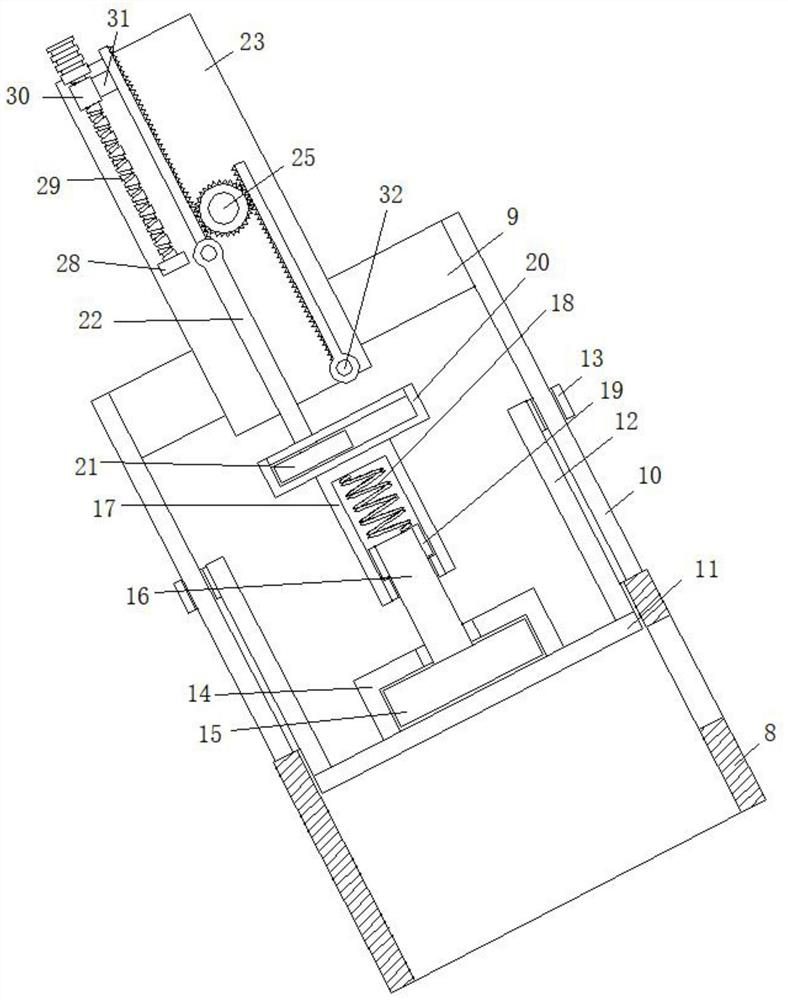

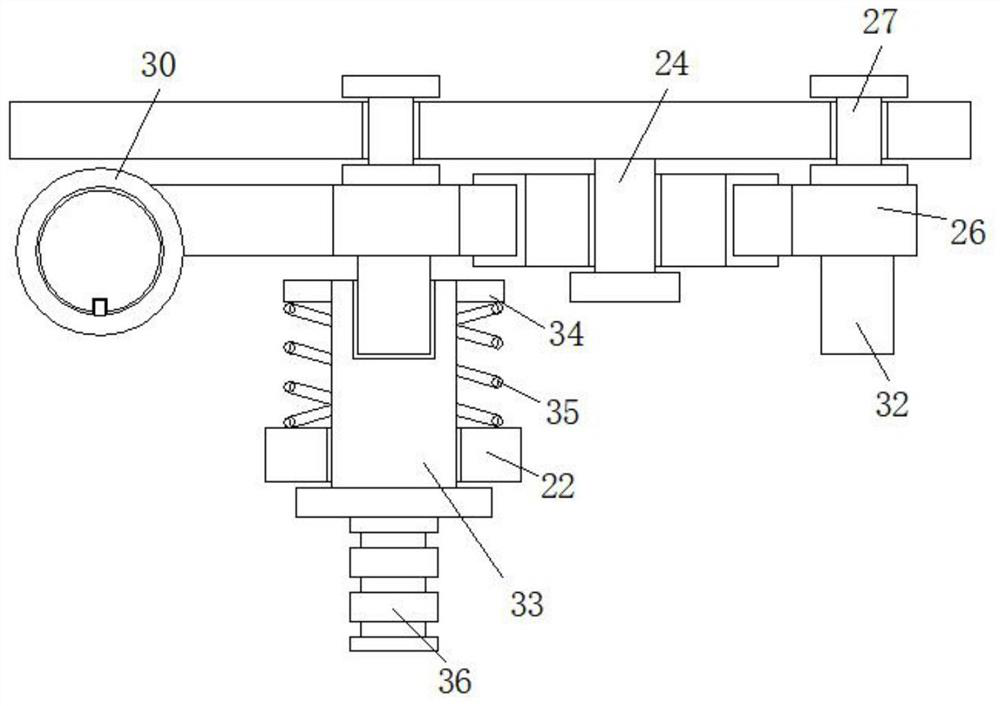

[0024] refer to Figure 1-4 , a kind of milling device for Trichosanthes finishing processing, comprises base plate 1, and the vertical upper part of base plate 1 is provided with milling box 2, and milling box 2 is arranged obliquely, and the bottom end of milling box 2 is an open structure, milling Between the bottom side of the box 2 and the bottom plate 1, a foot 3 is arranged, and a transmission roller 5 is installed to rotate between the inner walls of the grinding box 2. There is also a bottom support plate 7 fixedly connected between the inner walls of the powder box 2, the top side of the bottom support plate 7 is in contact with the top inner side of the grinding belt 6, and the top side of the powder box 2 is provided with a through hole and is fixedly connected with a feeding cylinder 8. The feeding cylinder 8 is arranged perpendicular to the milling box 2, and a mounting plate 9 is arranged obliquely above the feeding cylinder 8, and a support column 10 is fixedly...

Embodiment 2

[0027] like Figure 1-4As shown, this embodiment is basically the same as Embodiment 1. Preferably, a motor 37 is installed on one side of the milling box 2 and the installation vertical plate 23 respectively by bolts, and the output shaft of the motor 37 is respectively connected to the drive roller 5 and the reciprocating Leading screw 29 transmissions are connected.

[0028] In this embodiment, the drive roller 5 and the reciprocating lead screw 29 are driven by the motor 37 .

Embodiment 3

[0030] like Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the two sliding holes respectively have two I-shaped sliding blocks 27 , and the two I-shaped sliding blocks 27 are fixedly connected to both ends of the tooth plate 26 respectively.

[0031] In this embodiment, the arrangement of two I-shaped sliding blocks 27 makes the movement of the tooth plate 26 more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com