Processing technology for improving grinding flour yield of flour

A technology of processing technology and flour yield, applied in the field of wheat processing, can solve the problems of low flour yield in the flour grinding process, and achieve the effects of high scraping efficiency, good quality and improved flour yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

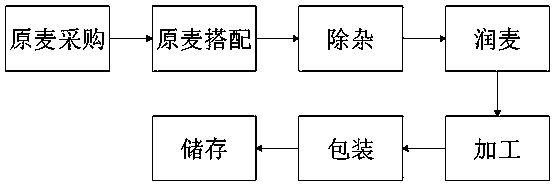

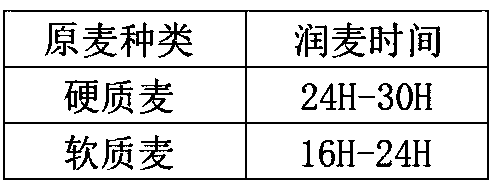

[0033] A. Procurement of raw wheat: When purchasing wheat, the location and season of wheat production have a direct impact on the flour extraction rate. White-skinned winter wheat has the advantages of thin skin, good quality and good color, high flour extraction rate, and red-skinned winter wheat The quality of winter and spring wheat is poor, and the flour extraction rate is low;

[0034] B. Matching of raw wheat: In view of the factors that affect the flour extraction rate due to different wheat raw materials, a wheat blending warehouse is set up to mix and match various wheats with different qualities, so that the wheat with different qualities can achieve the best flour extraction rate;

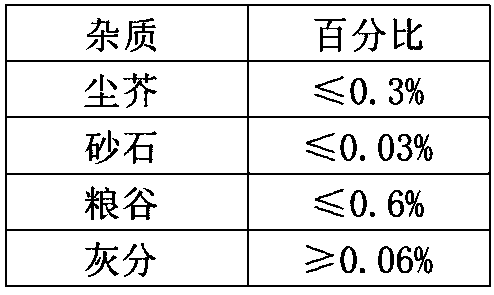

[0035] C. Impurity removal: Impurities in raw wheat after mixing will directly affect the quality of wheat flour. The standard for removal of impurities in wheat is: no more than 0.3% of dust mustard impurities, no more than 0.03% of sand and gravel, no more than 0.6% of grain impurities...

Embodiment 2

[0041] In embodiment one, add following operation:

[0042] The grinding rollers inside the skin grinding device are set to 4-5. The front skin grinding rollers are arranged blunt to blunt, with small tooth angles and small slopes. One, adding about 1.6 teeth per centimeter, the rear skin grinding rollers are arranged front to front, the relative tooth angle is large, the number of teeth is large, and the slope is large.

[0043] A. Procurement of raw wheat: When purchasing wheat, the location and season of wheat production have a direct impact on the flour extraction rate. White-skinned winter wheat has the advantages of thin skin, good quality and good color, high flour extraction rate, and red-skinned winter wheat The quality of winter and spring wheat is poor, and the flour extraction rate is low;

[0044] B. Matching of raw wheat: In view of the factors that affect the flour extraction rate due to different wheat raw materials, a wheat blending warehouse is set up to mix...

Embodiment 3

[0051] In embodiment two, add following operation:

[0052] The powder cleaning device is a powder cleaning machine. If the adjustments of the working state of the powder cleaning machine sieve surface, the flow rate of the powder cleaning machine, and the air volume of the powder cleaning machine are not performed properly, it will affect the effective separation of materials of different qualities, resulting in a decrease in the yield of good powder. Or the total powder yield is reduced.

[0053] A. Procurement of raw wheat: When purchasing wheat, the location and season of wheat production have a direct impact on the flour extraction rate. White-skinned winter wheat has the advantages of thin skin, good quality and good color, high flour extraction rate, and red-skinned winter wheat The quality of winter and spring wheat is poor, and the flour extraction rate is low;

[0054] B. Matching of raw wheat: In view of the factors that affect the flour extraction rate due to diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com