Necking device for aluminum alloy profile

A technology of aluminum alloy profiles and mouthpieces, applied in the field of sheet metal processing, can solve problems such as affecting the track shaping process, jamming, affecting normal use, etc., and achieve the effect of improving shaping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

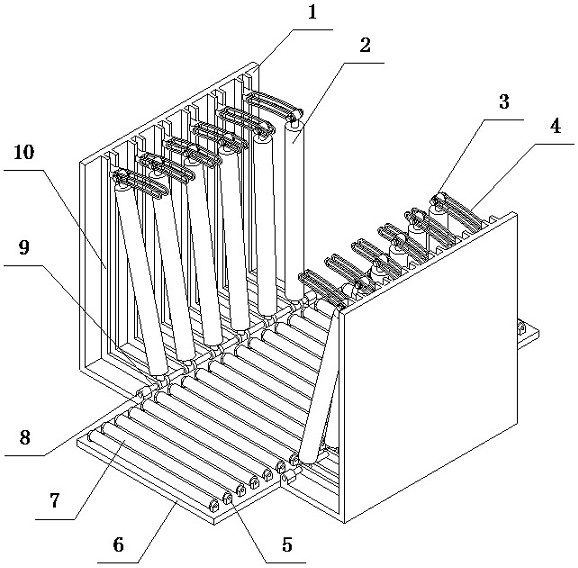

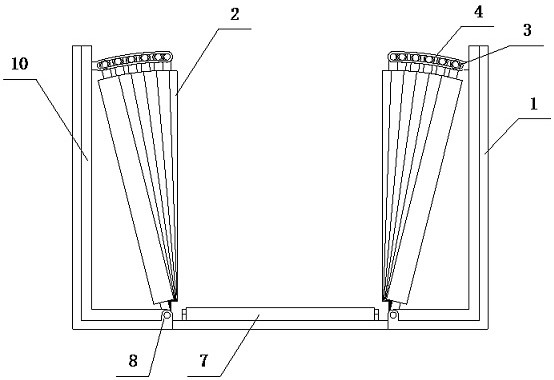

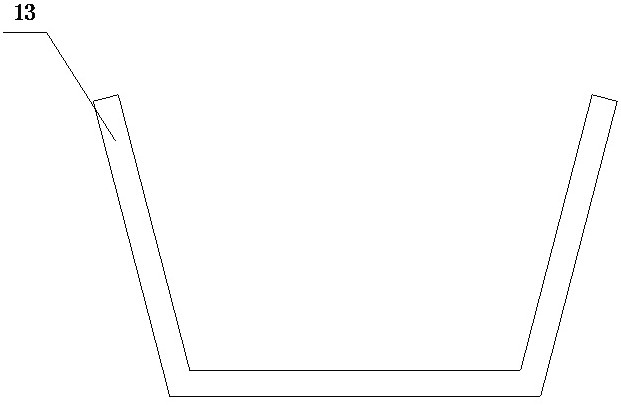

[0016] An aluminum alloy profile closing device of the present invention is realized in the following way: an aluminum alloy profile closing device of the present invention consists of a main body frame (1), a shaping roller (2), a fixing nut (3), a guide frame (4), and connecting ears (5), bottom plate (6), support roller (7), fixed ear (8), fixed shaft (9), fixed frame (10), connecting sleeve (11) and slide bar (12), two main frames (1) respectively placed on both sides of the guide frame (4), the main frame (1) is an L-shaped frame, the length of the main frame (1) is less than the length of the fixed frame (10), and multiple pairs of connecting ears ( 5) Equidistantly placed on the guide frame (4), a pair of connecting ears (5) are respectively close to both sides of the guide frame (4), and multiple support rollers (7) are placed on the guide frame (4), so The two ends of the supporting roller (7) are respectively connected to a pair of connecting ears (5), and the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com