A printer shaft with heat dissipation structure

A heat-dissipating structure and technology for printers, applied in printing devices, printing and other directions, can solve the problems of affecting the effect of printing, difficulty in maintenance and replacement, and inability to print normally, and achieve the effect of improving efficiency and increasing the effect of heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

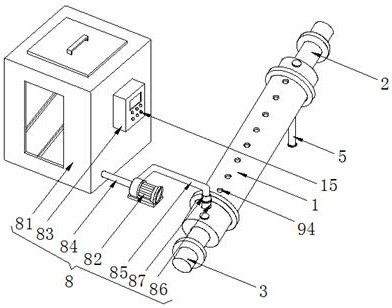

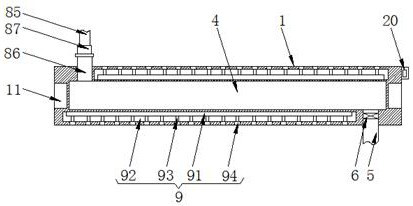

[0035]A printer shaft with a heat dissipation structure, comprising a shaft body 1 and two rotating shafts 2, the ends of the two rotating shafts 2 facing away from each other are fixedly connected with a connecting shaft 3, a cavity 4 is opened inside the shaft body 1, and the cavity The bottom of the right side of the cavity 4 is connected with the water outlet pipe 5, the bottom end of the water outlet pipe 5 runs through the shaft body 1 and extends to the outside of the shaft body 1, the top of the inner wall of the connecting pipe 86 and the outer surface of the threaded head 87 are fixedly connected with a sealing ring 10. A sealing ring 10 is provided at the joint between the connecting pipe 86 and the threaded head 87 to improve the sealing performance and prevent water overflow. The inside of the outlet pipe 5 is fixedly connected with a solenoid valve 6, and the top of the right side of the shaft body 1 is fixedly connected with a temperature sensor 7. , the model of...

Embodiment 2

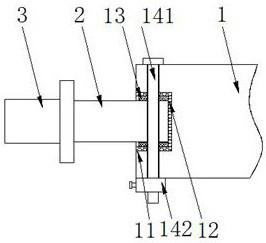

[0037] A printer shaft with a heat dissipation structure, comprising a shaft body 1 and two rotating shafts 2, both ends of the shaft body 1 are provided with fixing grooves 11 matching the rotating shafts 2, and the inner walls of the fixing grooves 11 are fixedly connected with The rubber pad 12, the surface of the rotating shaft 2 near the end of the shaft body 1 is fixedly connected with a rubber ring 13, and the rubber pad 12 and the rubber ring 13 increase the friction between the rotating shaft 2 and the fixed groove 11 while improving the sealing performance, thereby To improve the stability of the connection, the rubber pad 12 and the rubber ring 13 can be replaced to ensure elasticity. Both ends of the shaft body 1 are fixedly connected with a disassembly mechanism 14. It is set as a detachable connection, which is convenient for maintenance and replacement. It can be disassembled without using tools, and the operation is simple. The disassembly mechanism 14 includes ...

Embodiment 3

[0039] A printer shaft with a heat dissipation structure, including a shaft body 1 and two rotating shafts 2, the shaft body 1 includes a base layer 101, the top of the base layer 101 is sprayed with a high temperature resistant coating 102, and the high temperature resistant coating 102 is specifically silicone high temperature resistant coating, and the top of the high temperature-resistant coating 102 is sprayed with a wear-resistant coating 103, the wear-resistant coating 103 is made of epoxy resin material, the high-temperature resistant coating 102 and the wear-resistant coating 103 improve the resistance of the shaft body 1 Abrasion performance and high temperature resistance performance prolong the service life of the printer shaft. The ends of the two rotating shafts 2 facing away from each other are fixedly connected with the connecting shaft 3. The inside of the shaft body 1 is provided with a cavity 4, and the right side of the cavity 4 The bottom is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com