Full-automatic cleaning high-precision filtering equipment

A fully automatic cleaning and filtering equipment technology, applied in the direction of filtration treatment, water/sewage treatment equipment, special treatment targets, etc., can solve the problems of wasting water, poor recovery, and affecting the service life of filtering equipment, so as to save water and improve usage The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

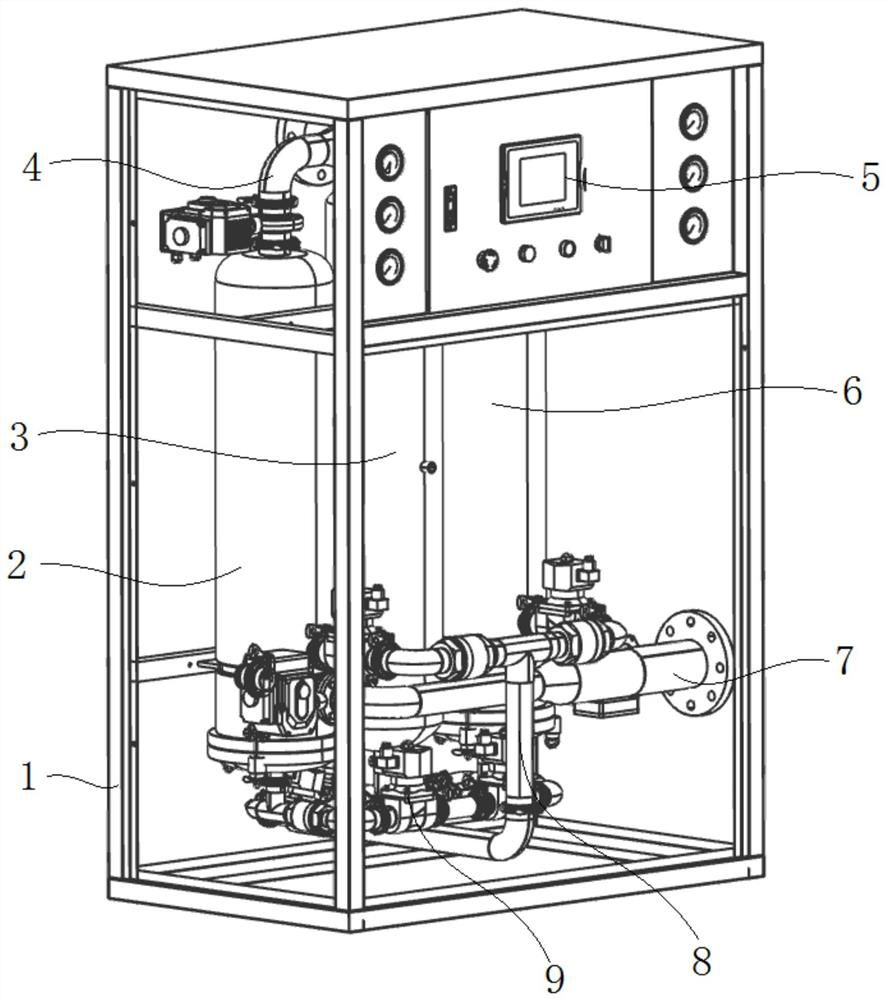

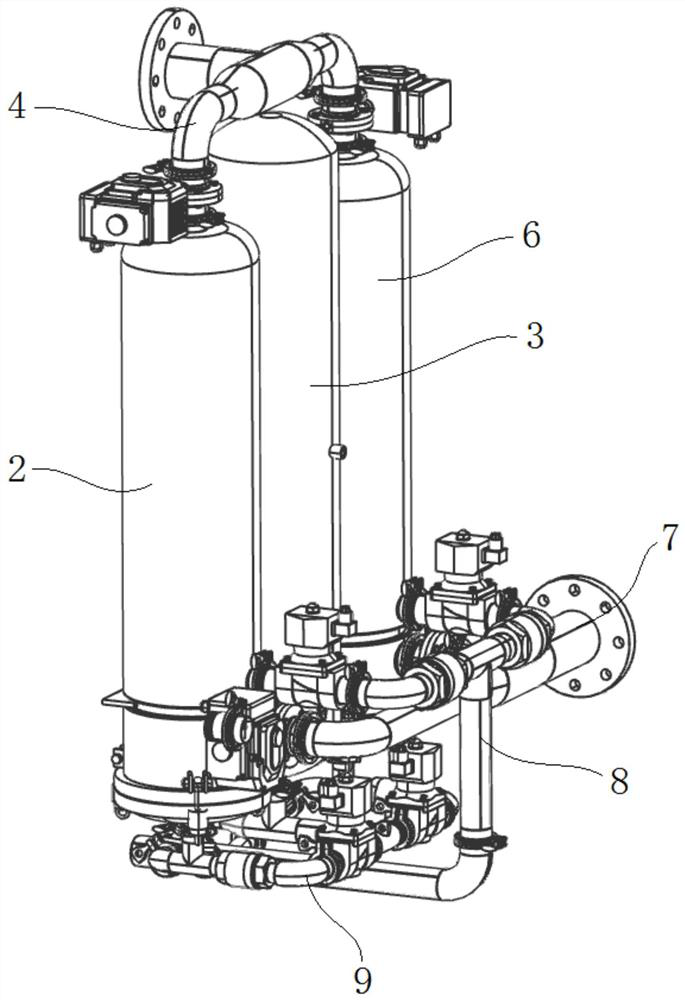

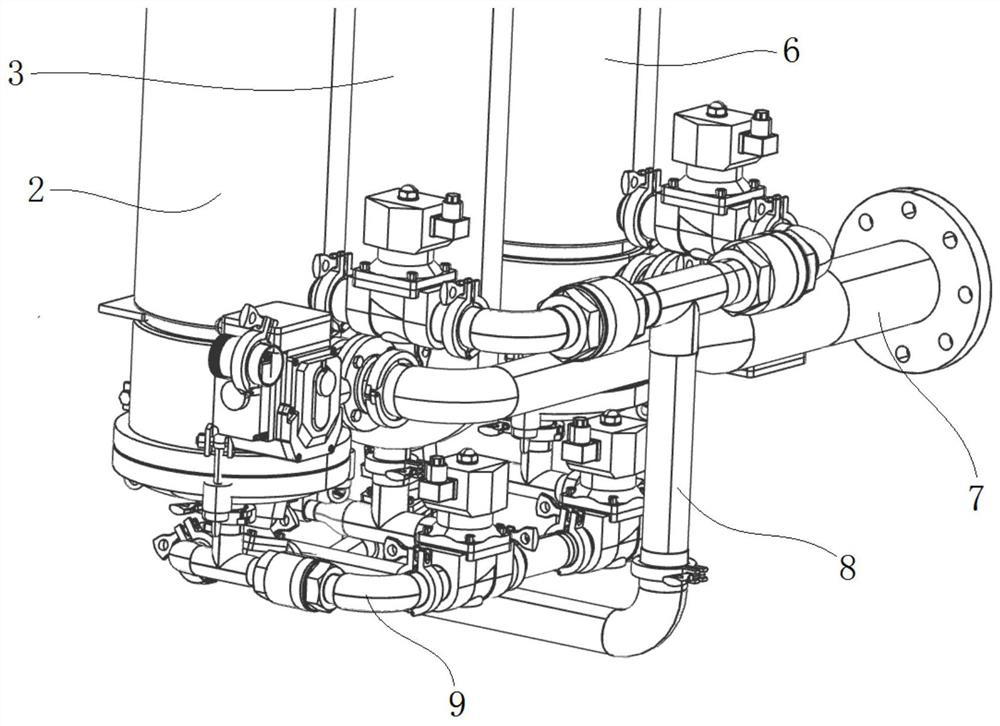

[0028] Such as Figure 1-3 As shown, the technical solution adopted in the present invention is: a fully automatic cleaning high-precision filter equipment, including a frame 1; a compressed gas source assembly 3 for providing cleaning gas is arranged on the frame, and is used to supply the cleaning gas The air delivery assembly 9 delivered to the filter assembly, and the filter assembly used to filter sewage to obtain filtered water and impurities; the compressed air source assembly 3 is connected to the air delivery assembly 9, and the air delivery assembly 9 is connected to the air delivery assembly 9. The filter assembly is connected; the filter assembly is provided with a drainage integrated assembly 7 for discharging filtered water; the filter assembly is provided with a sewage integrated assembly 8 for using cleaning gas to discharge impurities; wherein the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com