Relay shell mounting production line

A production line and relay technology, applied in relays, relay bases/shells/covers, circuits, etc., can solve the problem of low installation efficiency of relay shells, and achieve the effect of high degree of automation, simple structure and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

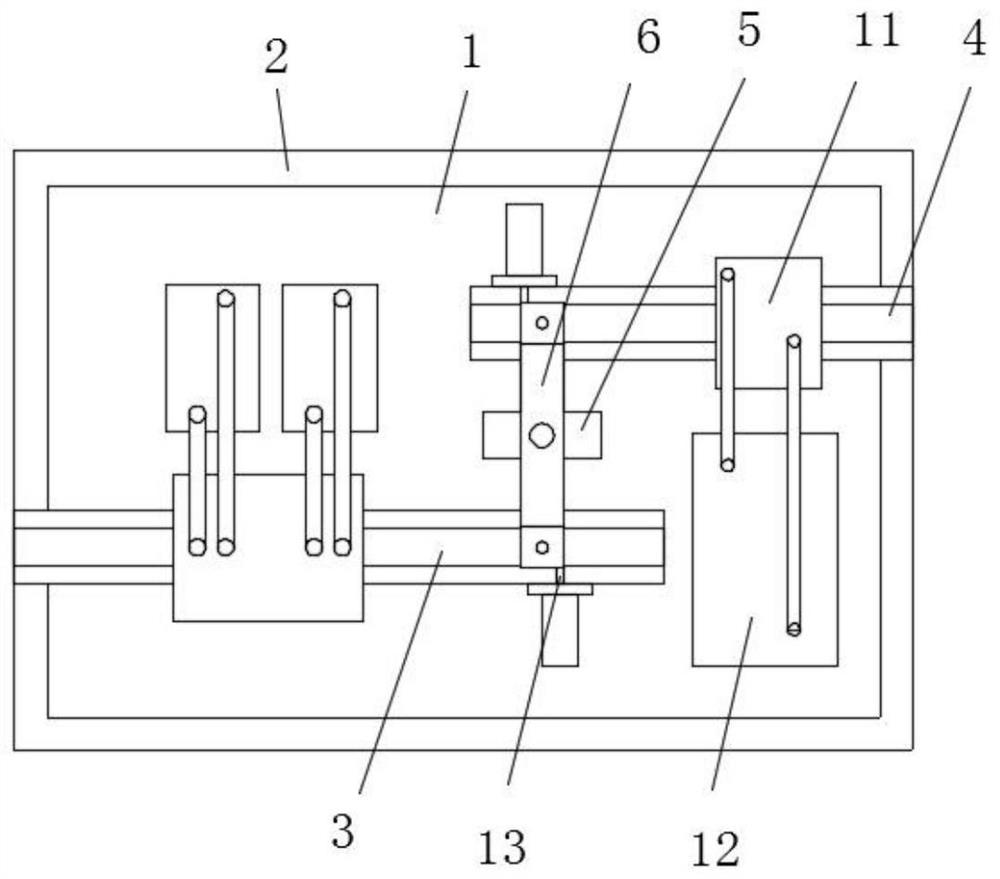

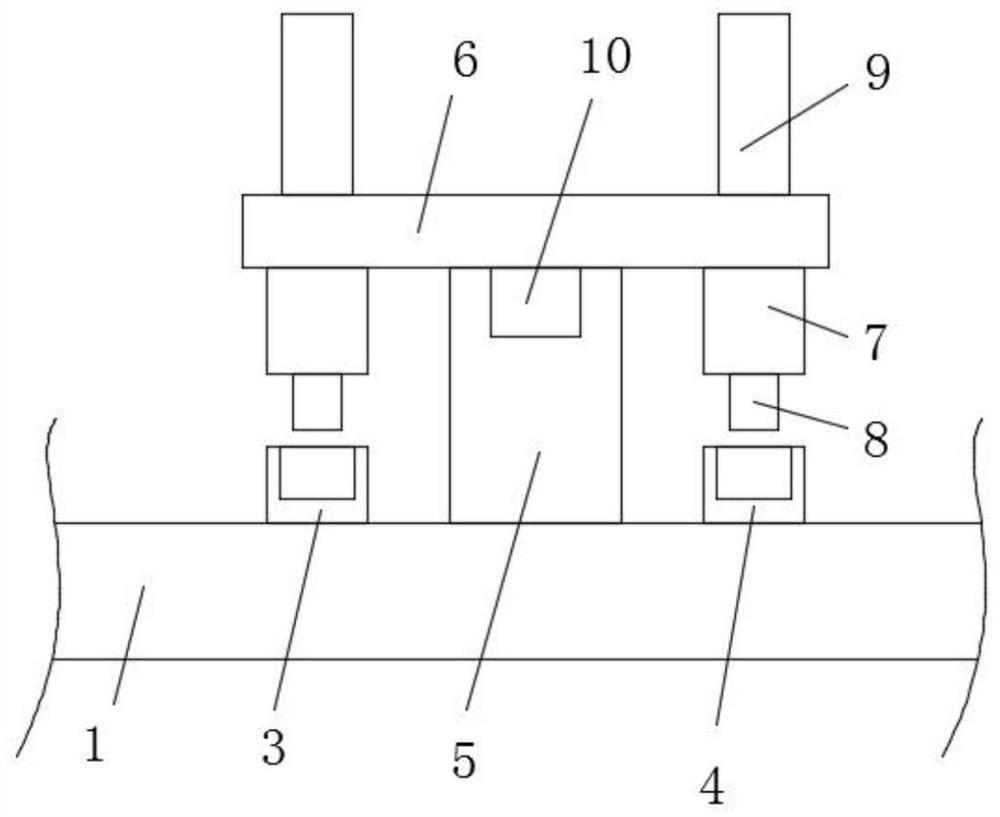

[0020] refer to Figure 1-2 , a relay shell installation production line, including a workbench 1 and an outer cover 2 fixed on the top of the workbench 1, two ends of the top of the workbench 1 are provided with a mounting frame conveyor belt 3 and a shell conveyor belt 4 arranged in parallel to each other, and the mounting frame conveyor belt 3 There is a support column 5 fixed on the top of the workbench 1 between the shell conveyor belt 4, and the top of the support column 5 is rotatably connected with a horizontal plate 6, and the bottoms of both ends of the horizontal plate 6 are equipped with a movable plate 7 slidingly connected with it. The bottom of each movable plate 7 is respectively fixed with mechanical claw one 8 and mechanical claw two. 9. The output end of the hydraulic cylinder 9 passes through the horizontal plate 6 and is fixed on the top of the movable plate 7. The electric turntable 10 is embedded in the top of the support column 5, and the horizontal pla...

Embodiment 2

[0024] refer to Figure 1-2 , a relay casing installation production line, the same as the first embodiment, the difference between this embodiment and the first embodiment is that a blowing mechanism 1 is provided directly above the casing conveyor belt 4, and the blowing mechanism 1 is included directly above the casing conveyor belt 4 The end cover 11 moving up and down, the filter box 12 located on one side of the shell conveyor belt 4, the air inlet pipe and the air outlet pipe connecting the end cover 11 and the filter box 12, and the negative pressure fan and filter screen located in the filter box 12, the end cover 11 It is an E-shaped structure, the bottom of the end cover 11 is tightly pressed on the top of the housing conveyor belt 4, the installation frame conveyor belt 3 is provided with an air blowing mechanism 2 having the same structure as the blowing mechanism 1, and the bottom of the filter box 12 is provided for the mounting frame conveyor belt 3 to pass thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com