Automatic pulse dust removal cleaning system and method based on pressure detection

An automatic pulse and pressure technology, applied in the field of sanitation vehicles, can solve problems such as variation, time-consuming and laborious, and inability to automatically feed back filter cartridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

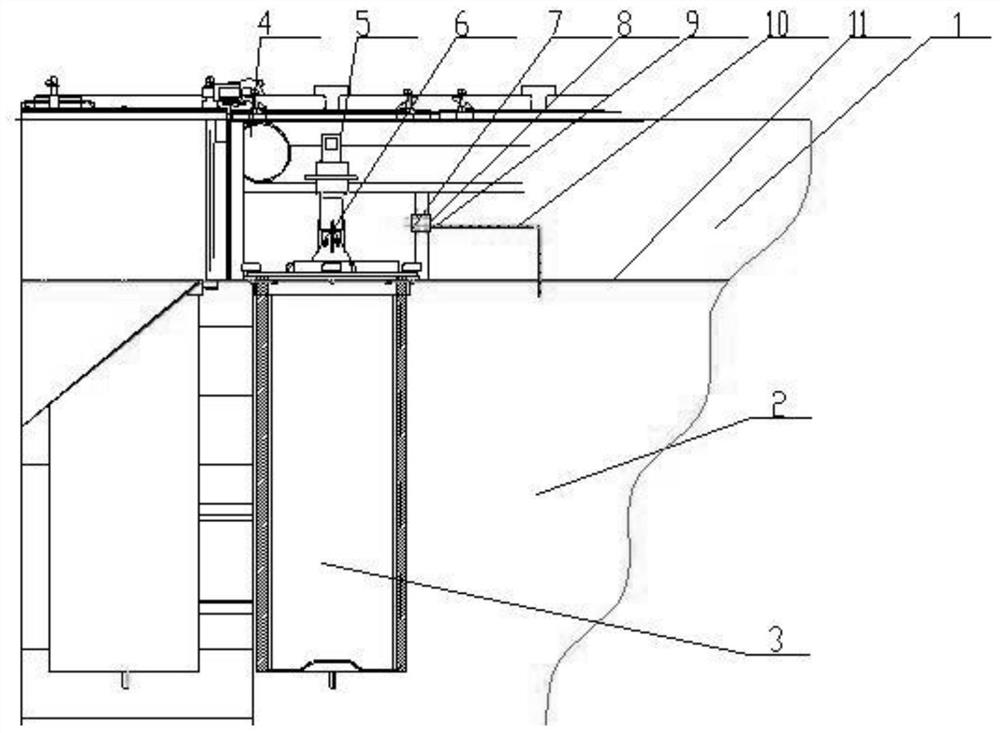

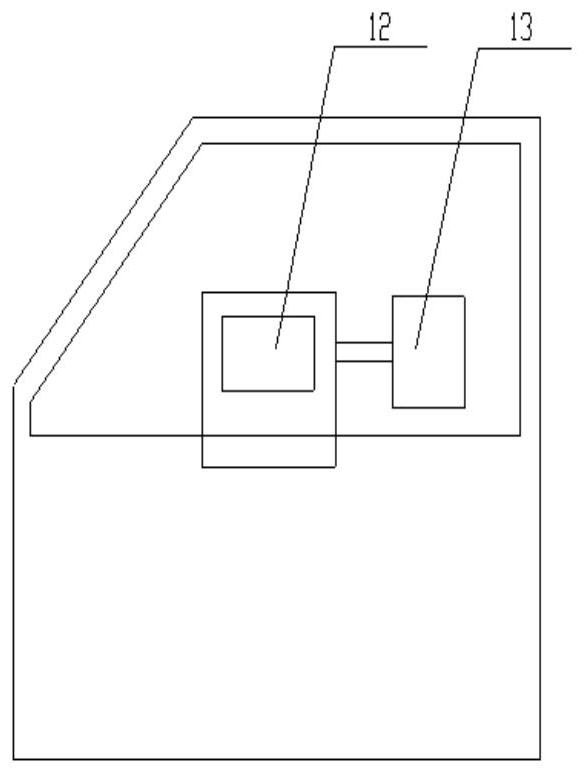

[0029] The invention provides an automatic pulse dust removal and cleaning system based on pressure detection, such as figure 1 As shown, it includes a purified air chamber 1, a filtered air chamber 2, a filter cartridge 3, an air bag 4, a pulse valve 5, an air injection hole 6, a differential pressure gauge 7, a first measuring port 8, a second measuring port 9, an air pipe 10, Partition 11 , cab controller 12 and monitor 13 . The purified gas chamber 1 and the filtered gas chamber 2 are of an integral box structure, and the purified gas chamber 1 and the filtered gas chamber 2 are separated by a partition 11 . The filter cartridge 3 is installed in the filter air chamber 2, and the filter air chamber 2 communicates with the dustbin.

[0030] The filter cartridge 3 includes an inner ring filter element and an outer ring filter layer. The top of the inner ring filter element extends into the purified air chamber 1. After the gas in the filtered air chamber 2 enters the filter...

Embodiment 2

[0036] The present invention provides an automatic pulse dust removal and cleaning method based on pressure detection. The device used in this method is the device in Embodiment 1, and the device part will not be described in detail in this embodiment. This method comprises the steps:

[0037] Step 1. Monitor the pressure difference between the inside of the filter cartridge and the outside of the filter cartridge through the differential pressure gauge 7 .

[0038] Step 2. When the differential pressure of the differential pressure gauge 7 reaches the preset minimum (i.e., the filter cartridge tends to be clogged), the cab controller 12 controls the pulse valve 5 to appropriately increase the injection time of the pulse valve and reduce the injection interval. The stored compressed air of the air bag 4 is blown to the inside of the filter cartridge through the air injection hole 6, and the blockage of the filter cartridge is quickly cleared. Once the blockage is removed, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap