Dust removal spraying system for building safety engineering

A technology of spraying system and safety engineering, applied in the field of dust removal spraying system for building safety engineering, can solve problems such as water resource waste, and achieve the effect of increasing the spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

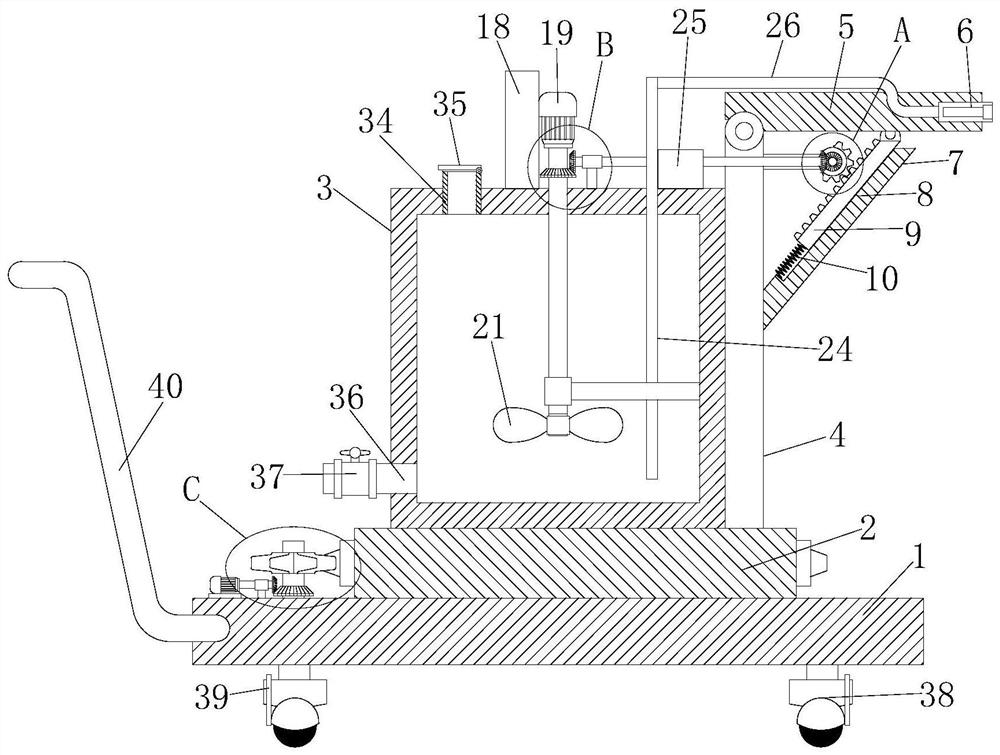

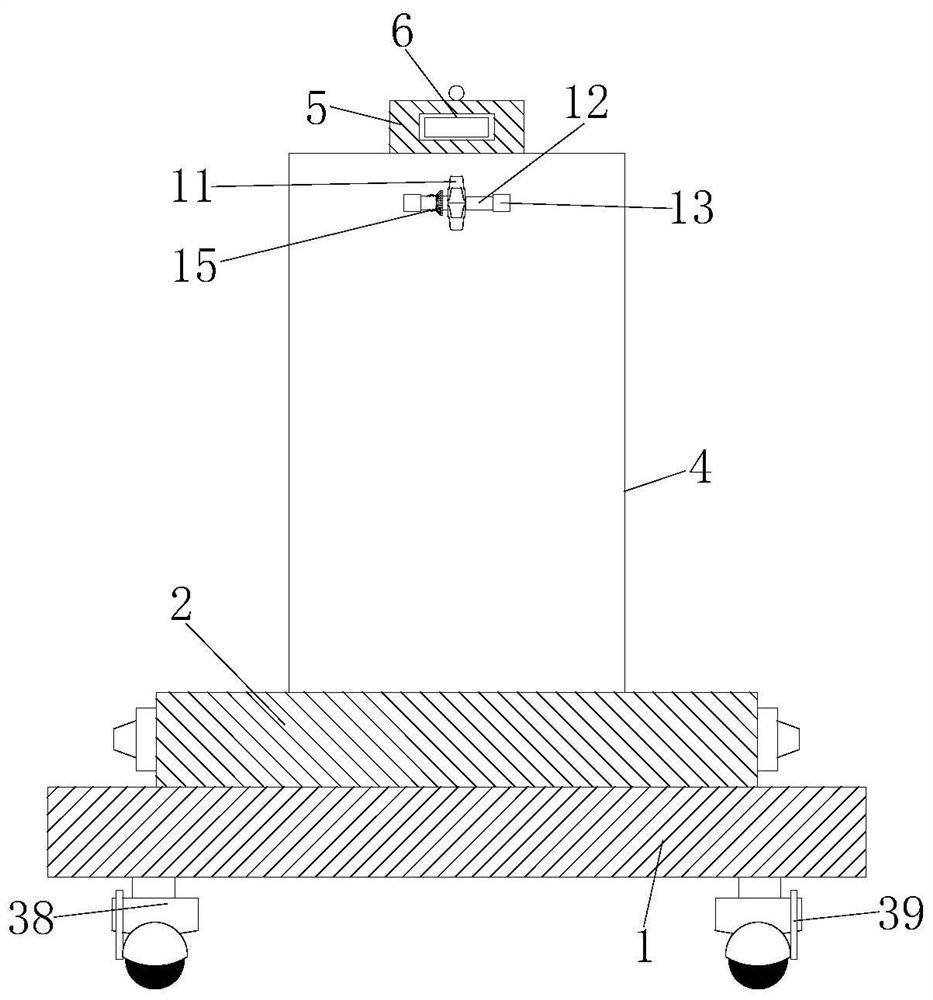

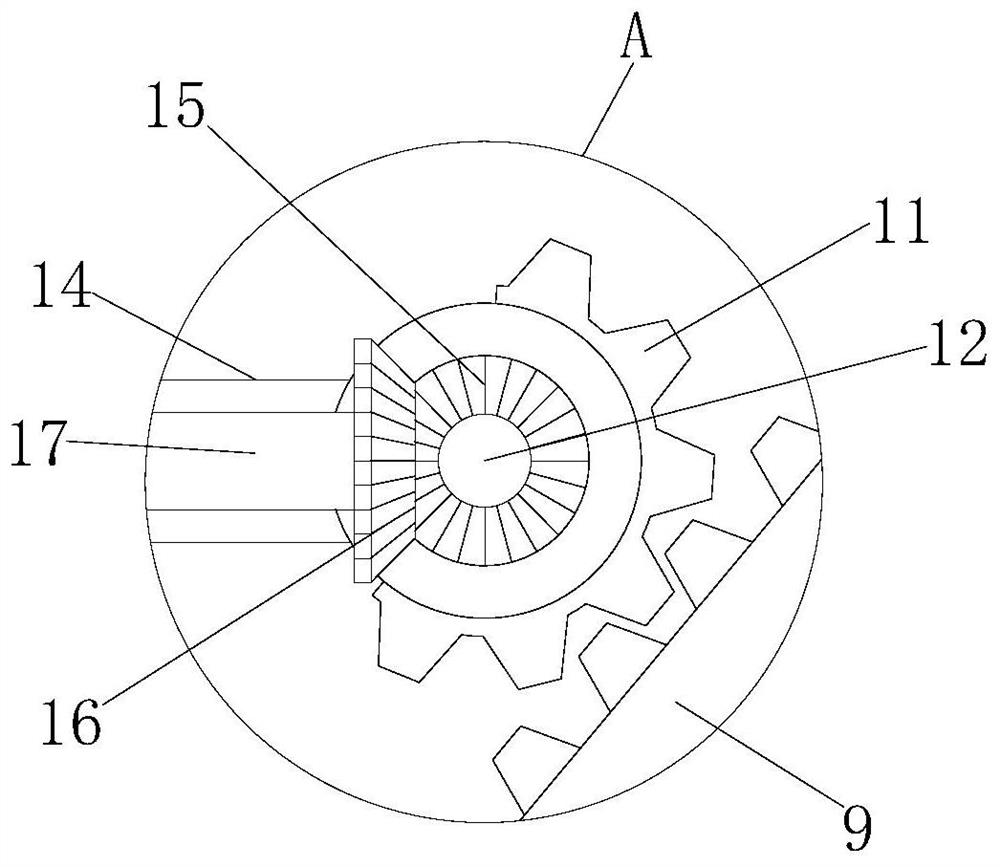

[0027] refer to Figure 1-5 , a dust removal and spraying system for building safety engineering, comprising a bottom plate 1, the top of the bottom plate 1 is rotatably connected to a turntable 2, the top of the turntable 2 is fixedly connected to a water tank 3 and a side plate 4, and the side plate 4 is fixedly connected to a part of the water tank 3 Side, the top of the side plate 4 is hingedly connected with a horizontal plate 5, one end of the horizontal plate 5 is fixedly provided with an atomizing nozzle 6, one side of the side plate 4 is fixedly connected with a slanting rod 7, and a chute 8 is provided on the slanting rod 7, A rack 9 is slidably connected in the chute 8, and one end of a spring 10 is fixedly connected to the bottom end of the rack 9, and the other end of the spring 10 is fixedly connected to the inner wall of the bottom of the chute 8, and a sector gear is engaged on the rack 9 11. The first roller 12 is fixed on the sector gear 11, and the two ends ...

Embodiment 2

[0038] refer to Figure 1-5, a dust removal and spraying system for building safety engineering, comprising a bottom plate 1, the top of the bottom plate 1 is rotatably connected with a turntable 2, the top of the turntable 2 is fixedly welded with a water tank 3 and a side plate 4, and the side plate 4 is fixedly welded to a part of the water tank 3 Side, the top of the side plate 4 is hingedly connected with a horizontal plate 5, one end of the horizontal plate 5 is fixedly provided with an atomizing nozzle 6, one side of the side plate 4 is fixedly welded with a slanting rod 7, and a chute 8 is opened on the slanting rod 7, The chute 8 is slidingly connected with a rack 9, the bottom end of the rack 9 is fixedly welded with one end of the spring 10, and the other end of the spring 10 is fixedly welded on the bottom inner wall of the chute 8, and the rack 9 is meshed with a sector gear 11. The first roller 12 is fixedly set on the sector gear 11, and the two ends of the firs...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap