Composite catalyst for electro-Fenton degradation of dye wastewater as well as preparation method and application of composite catalyst

A technology for composite catalyst and dye wastewater, which is applied in the field of composite catalyst preparation and can solve the problem of low catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

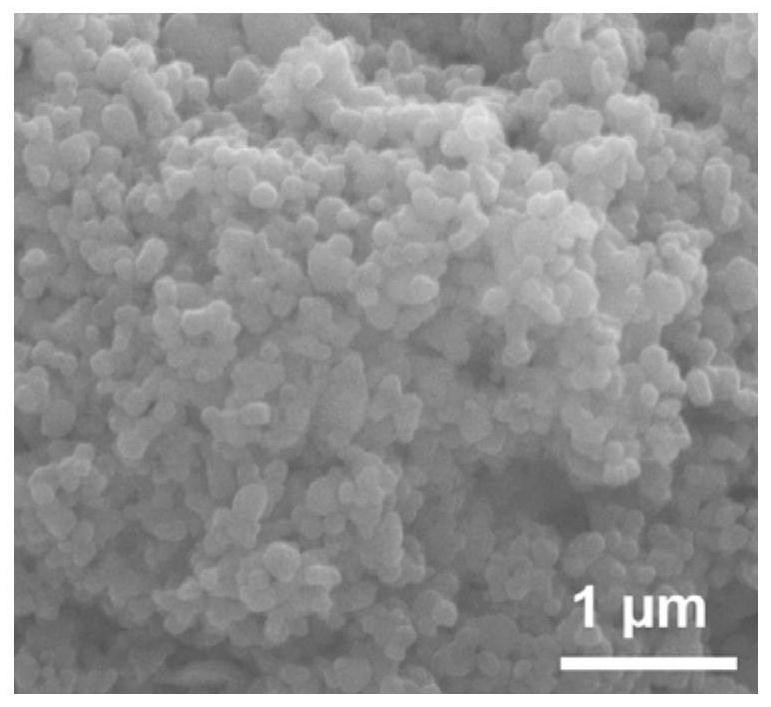

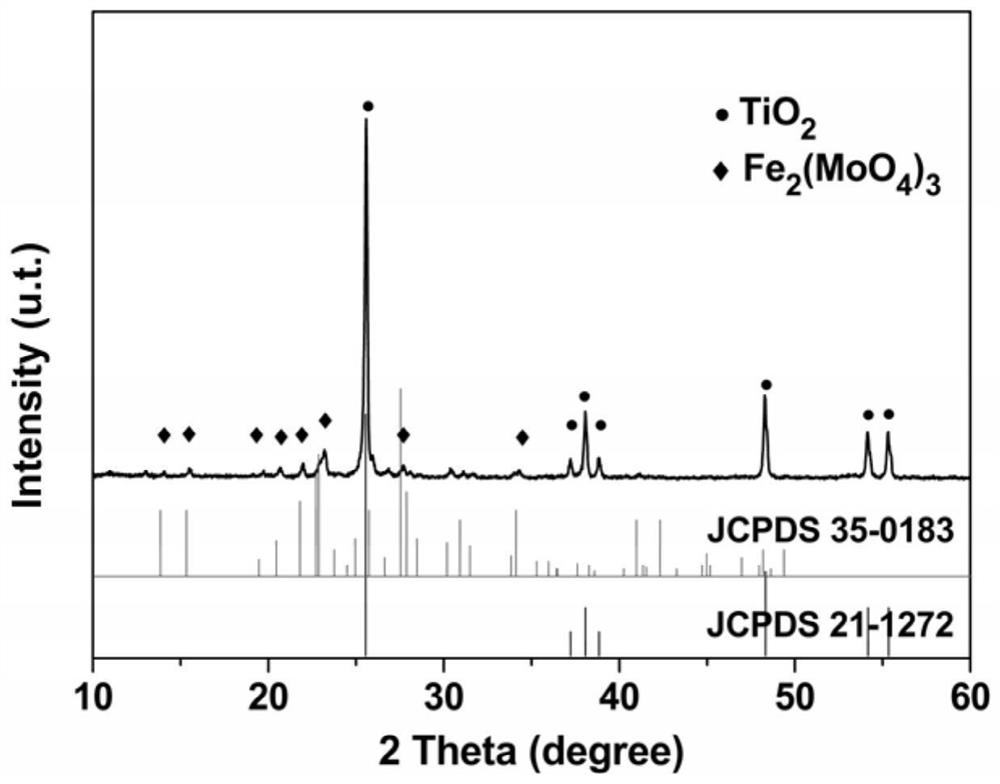

Image

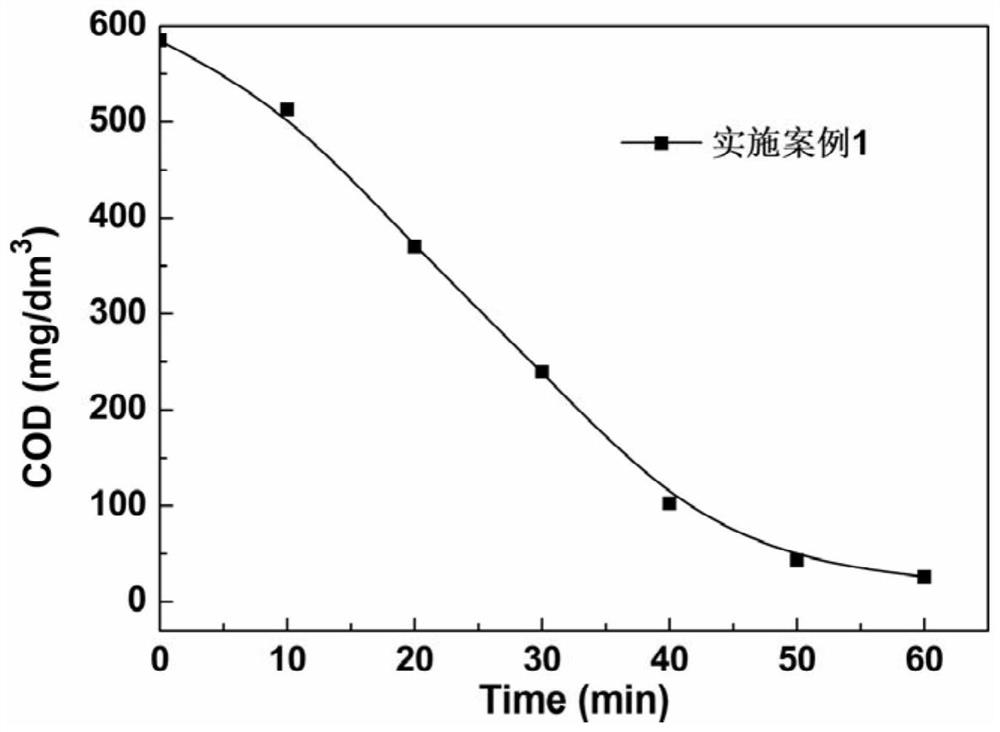

Examples

Embodiment example 1

[0025] 1) Weigh 0.12g TiO 2 The powder was mixed with 5mL of isopropanol and ultrasonically dispersed for 15min, and then added dropwise to 50mL of deionized water to obtain TiO with a concentration of 0.03mol / L. 2 Dispersions;

[0026] 2) take by weighing 0.3g ammonium molybdate and 0.324g anhydrous ferric chloride respectively, respectively dissolve in 5mL deionized water and make ammonium molybdate solution and ferric chloride solution;

[0027] 3) Under ultrasonic dispersion conditions, ammonium molybdate solution was added dropwise to TiO 2 In the dispersion solution, adjust the pH value of the mixed solution to 4 with hydrochloric acid, and then ultrasonically mix for 2 hours;

[0028] 4) Under the condition of ultrasonic dispersion, add the ferric chloride solution dropwise to the above mixture and continue ultrasonic mixing for 0.5-1 hour, and then let it stand for 2 hours;

[0029] 5) Filter the precipitate, wash it with deionized water until neutral, place it in a...

Embodiment example 2

[0035] 1) Weigh 0.12g TiO 2 The powder was mixed with 5mL of isopropanol and ultrasonically dispersed for 15min, and then added dropwise to 50mL of deionized water to obtain TiO with a concentration of 0.03mol / L. 2 Dispersions;

[0036] 2) Take by weighing 0.15g ammonium molybdate and 0.124g anhydrous ferric chloride respectively, respectively dissolve in 5mL deionized water and make ammonium molybdate solution and ferric chloride solution;

[0037] 3) Under ultrasonic dispersion conditions, ammonium molybdate solution was added dropwise to TiO 2 In the dispersion solution, adjust the pH value of the mixed solution to 4 with hydrochloric acid, and then ultrasonically mix for 2 hours;

[0038] 4) Under the condition of ultrasonic dispersion, add the ferric chloride solution dropwise to the above mixture and continue ultrasonic mixing for 0.5-1 hour, and then let it stand for 2 hours;

[0039] 5) Filter the precipitate, wash it with deionized water until neutral, place it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com