Automatic thread threading machine for fiber reinforced composite circular tube and circular bar

A composite material, fiber-reinforced technology, applied in the mechanical field, can solve the problems of continuity failure, easy delamination and peeling of threads, and reduced success rate of threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

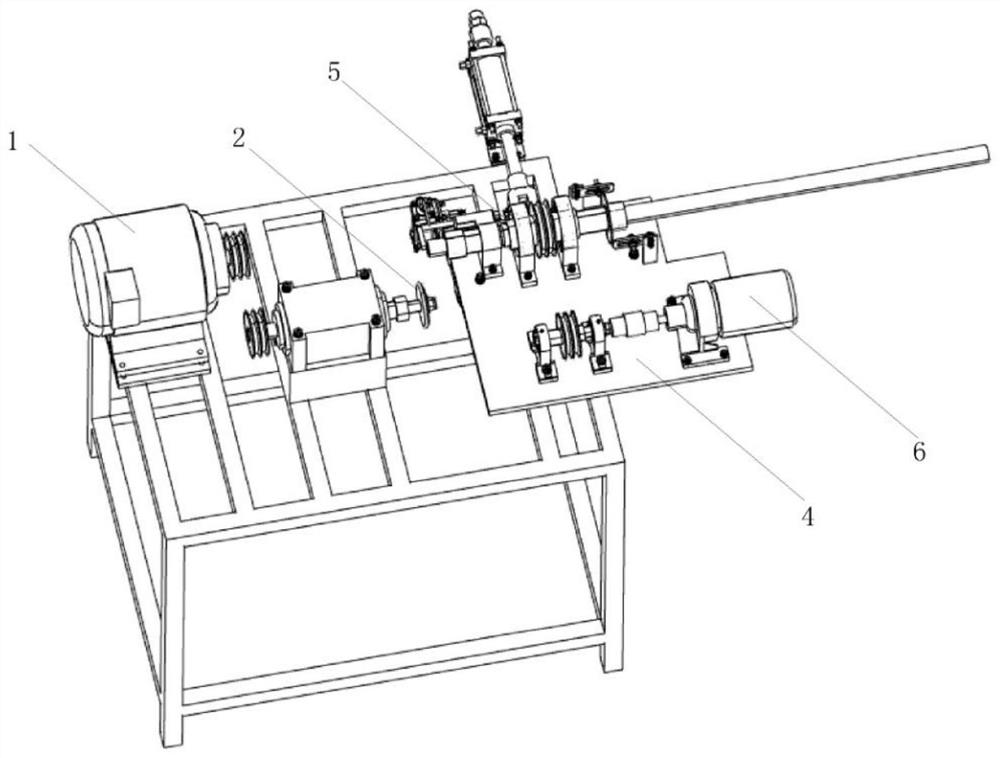

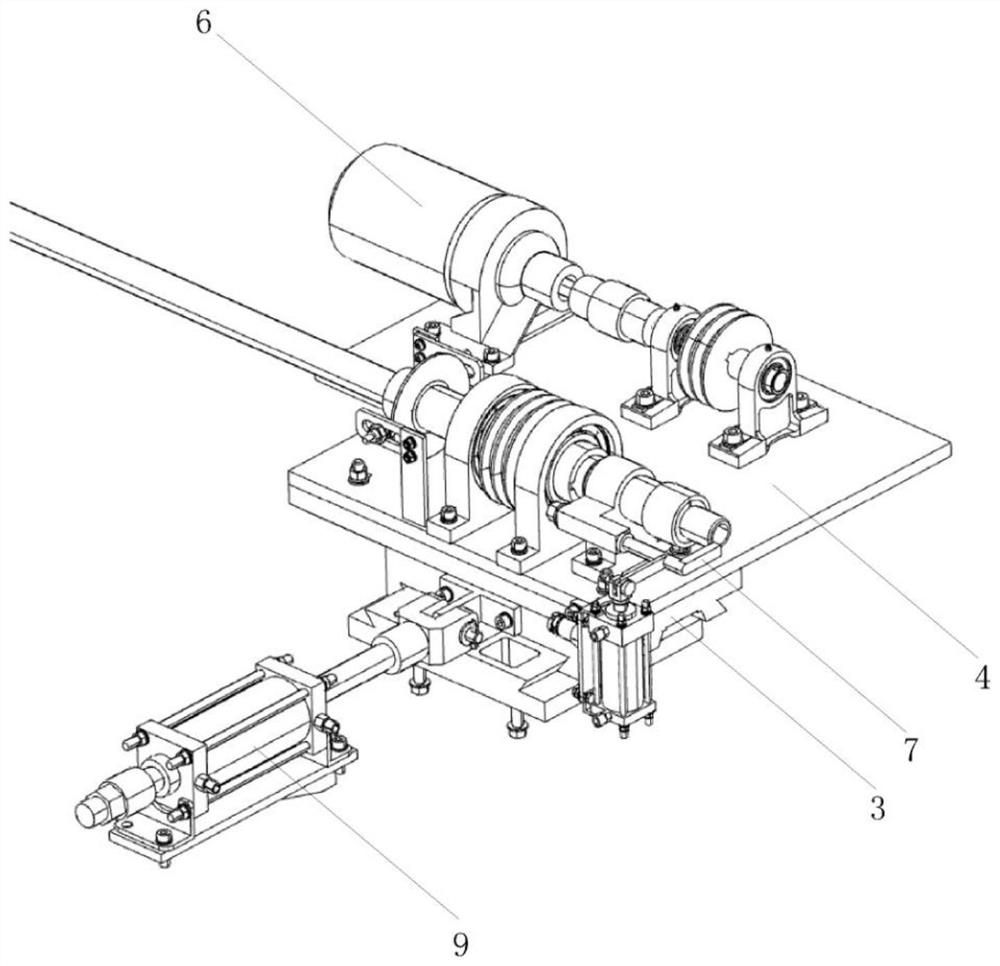

[0020] Specific embodiment 2: an automatic thread threading machine for round pipes and rods made of fiber-reinforced composite materials, which is characterized in that it includes a molar grinding wheel 2 driven by a motor 1, and a cross support plate 3 is arranged on the front side of the molar grinding wheel 2, Work platform 4 is set on the cross support plate 3, feed screw sleeve 5 is installed on work platform 4, feed screw sleeve 5 is driven by the motor 2 6 on the work platform 4, drives work platform 4 to advance by the movement of cross support plate 3 Move the screw sleeve 5, so that the round tube round rod and the molar grinding wheel 2 work together.

[0021] Working method: a. Install the round tube and rod in the feed screw sleeve and position it; b. Drive the cross plate through the cylinder to drive the working platform to move, and then make the round tube and rod thread with the molar grinding wheel; c. Molar The first motor of the grinding wheel, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com