Auxiliary blanking device for automobile shaft parts based on magnetic strip adsorption

A technology for assisting blanking and automobile axles, applied in the field of auto parts, can solve the problems of easy slippage, insufficient friction, wear and damage on the surface of parts, and achieve the effect of facilitating the fastening operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

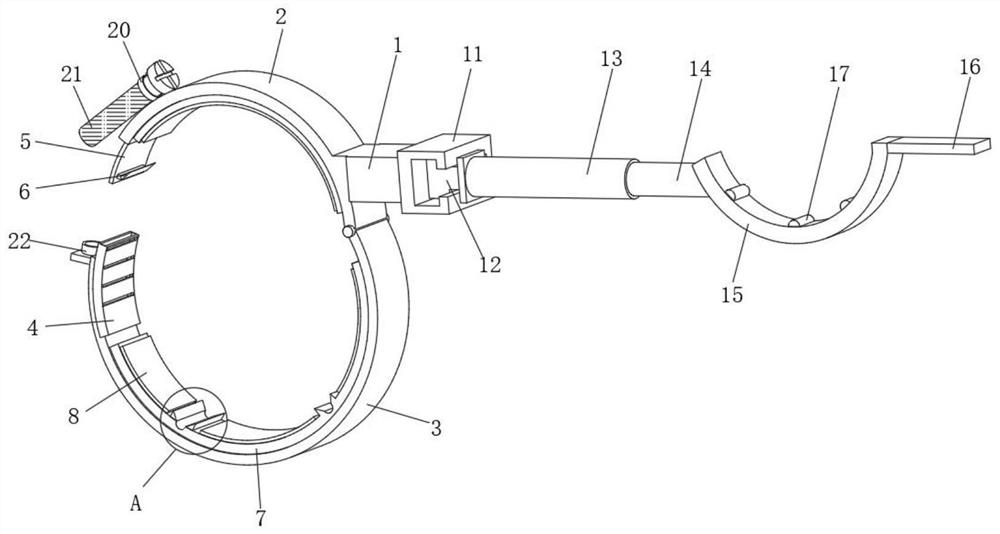

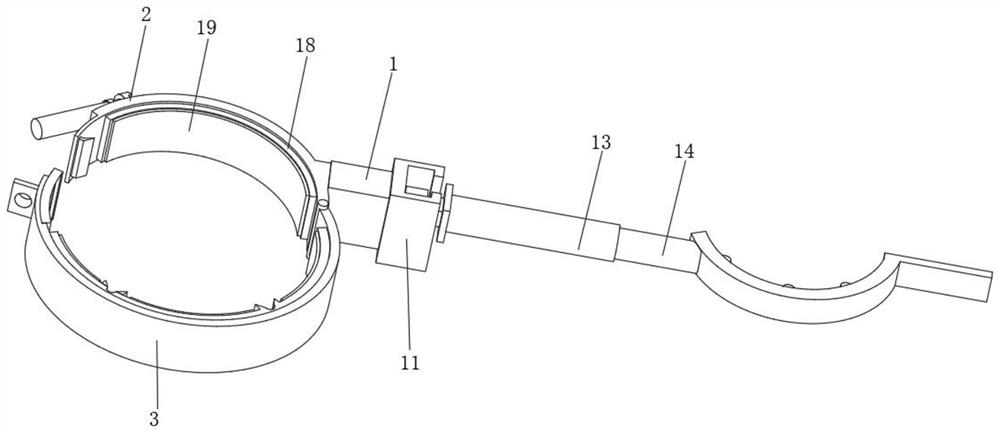

[0035] Such as Figure 1-3As shown, the present invention provides a technical solution: an auxiliary blanking device for automobile shaft parts based on magnetic strip adsorption, including a support link 1, and the left side of the support link 1 is fixedly connected with a support fastening groove 2, The bottom end on the right side of the supporting fastening groove 2 is connected with the movable clamping groove 3 through the damping shaft rotation, and the left side of the movable clamping groove 3 and close to the upper position are fixedly connected with the fastening limiting plate 4, and the left side of the supporting fastening groove 2 The bottom of the fastening rod 5 is fixedly connected with a fastening rod 5, and the inner side of the fastening rod 5 near the bottom is fixedly connected with an adjustment clamping mechanism 6, and the adjusting clamping mechanism 6 is correspondingly clamped with the fastening limiting plate 4. The inner surface of the rubber b...

Embodiment 2

[0041] Such as Figure 1-2 As shown in and 4, on the basis of Embodiment 1, the present invention provides a technical solution: an auxiliary blanking device for automotive shaft parts based on magnetic strip adsorption, supporting the outside of the fastening groove 2 and the position near the left side The auxiliary bearing 20 is fixedly connected, and the inside of the auxiliary bearing 20 is penetrated and connected with fastening bolts 21 for rotation.

[0042] A restricting threaded block 22 is fixedly connected to the outer side of the movable clip groove 3 and close to the upper position, and the fastening bolt 21 corresponds to the restricting threaded block 22 and is threaded.

[0043] The top of the fastening limiting plate 4 is provided with an inner slot 23, and the inner surface of the fastening limiting plate 4 is evenly provided with a limiting card slot 24, and the adjusting clamping mechanism 6 is correspondingly clamped with the limiting card slot 24 inside....

Embodiment 3

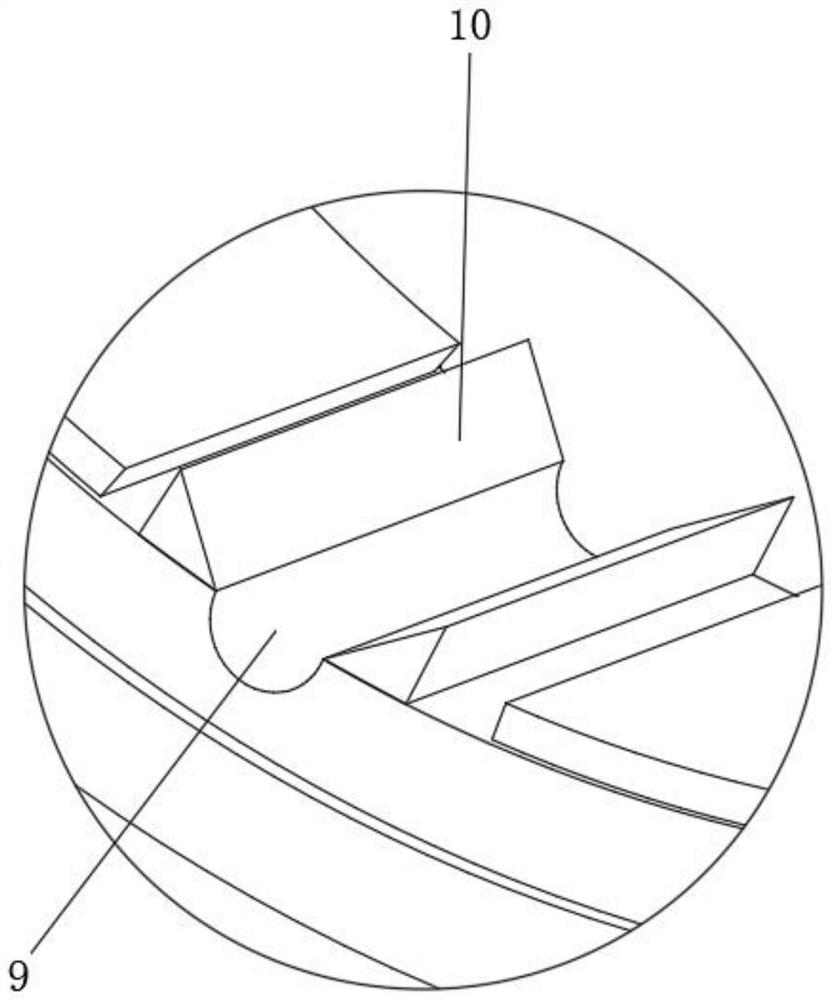

[0045] Such as Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: an auxiliary blanking device for automobile shaft parts based on magnetic strip adsorption, and the adjustment clamping mechanism 6 includes a support frame 601 , the right side of the support frame 601 runs through and is slidably connected with a movable contact bar 602 , the right side of the movable contact bar 602 is fixedly connected with a limiting insert 603 , and one end of the movable contact bar 602 located inside the support frame 601 is fixedly connected There is an adjustment spring 604 . Realize the pre-clamping between the device and the axle of the car, which is convenient for workers to perform subsequent fastening operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com