Soaking type cooling device for plastic pipe production

A technology for plastic pipes and cooling devices, applied in the field of pipe production, can solve the problems of low heat carried by pumped water, inability to make full use of water, and rising water temperature, so as to save water consumption, reduce friction, slow down The effect of the rate of warming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

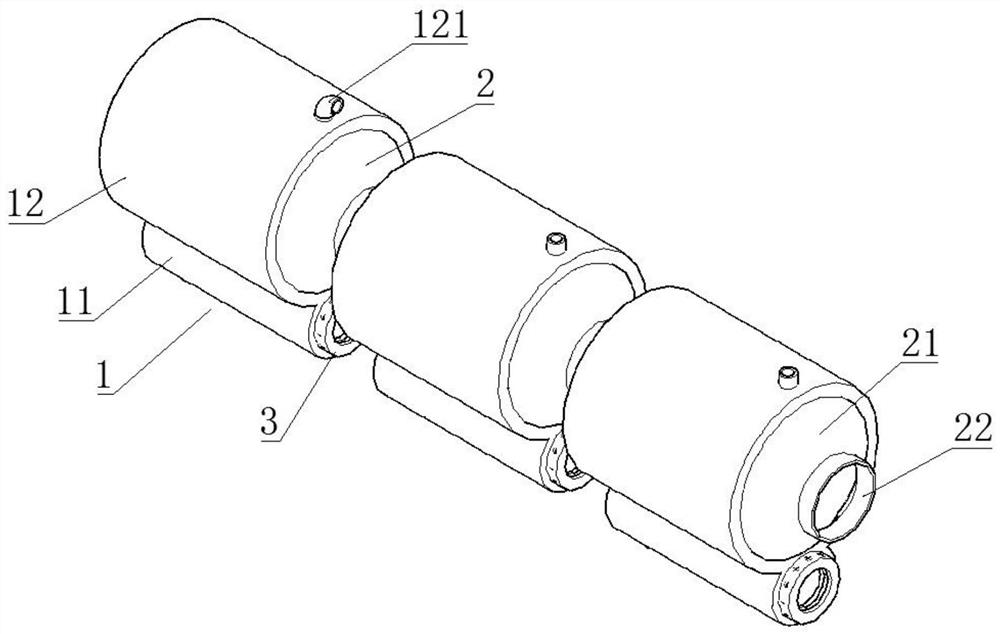

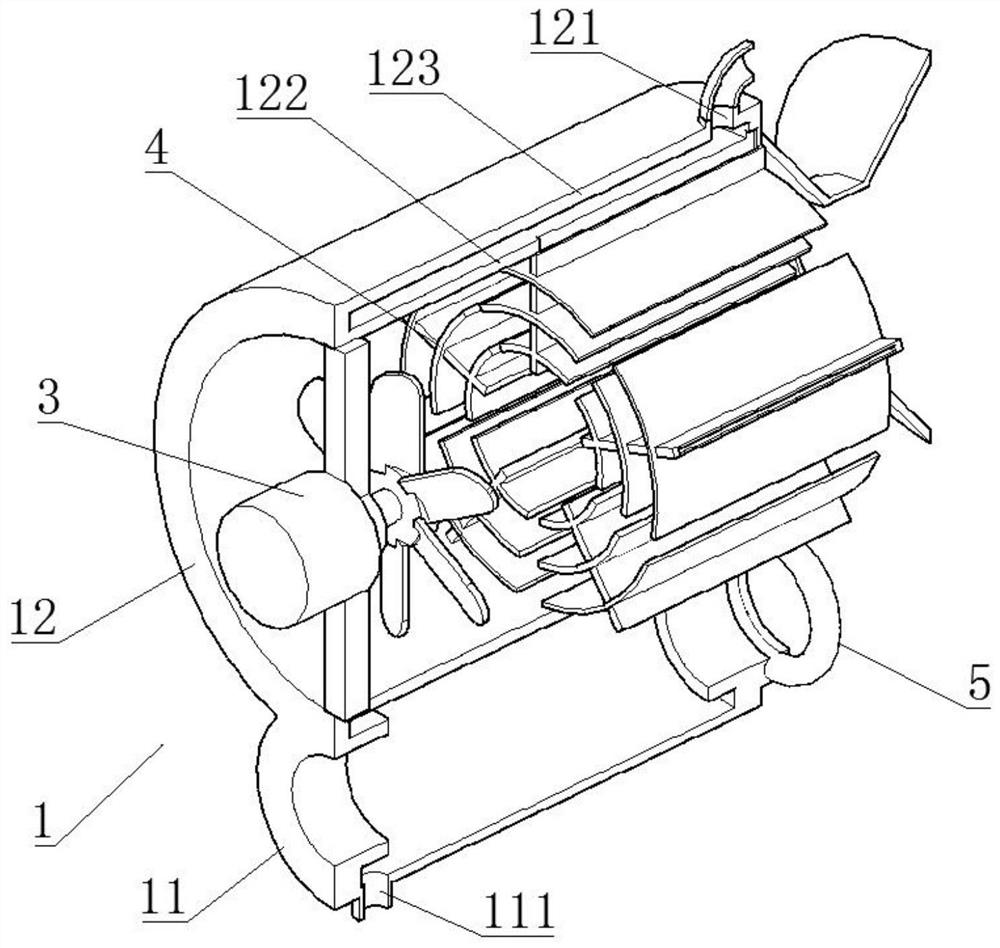

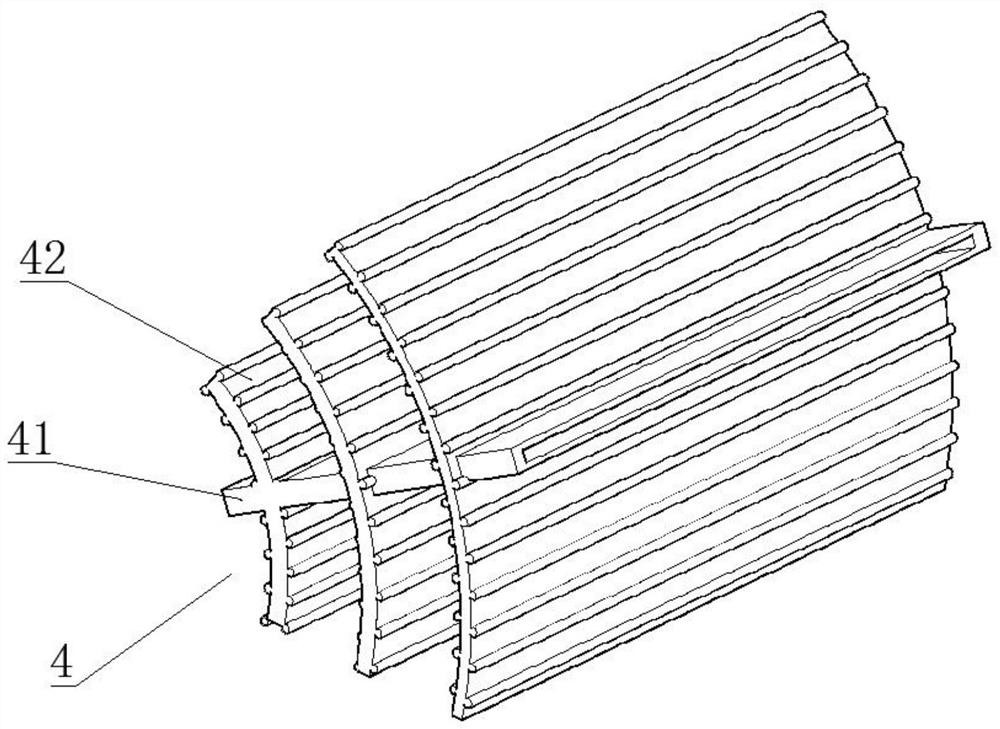

[0037] Such as Figure 1-2 As shown, an immersion cooling device for plastic pipe production includes a cooling tube 1, the cooling tube 1 includes a tube tube 11, the inside of the tube tube 11 is hollow, the top of the tube tube 11 communicates with the bottom end of the cooling tube 12, and the cooling tube 12 includes a bottom The end of the outer cylinder 123 is fixedly connected to the tube 11, the end of the outer cylinder 123 is fixedly connected to the inner cylinder 122, and the inner wall of the inner cylinder 122 is fixedly connected to the heat dissipation frame 4, and the left end of the heat dissipation frame 4 in the inner cylinder 122 is provided with a fan. The heat dissipation frame 4 includes a frame plate 41 fixedly connected to the inner cylinder 122. The fan-shaped fins 42 coaxial with the inner cylinder 122 are fixedly connected to the frame plate 41. There are several cooling cylinders 1, and several cooling cylinders 1 form a linear array and pass thro...

Embodiment 2

[0040] Such as Figure 1-3As shown, an immersion cooling device for plastic pipe production includes a cooling tube 1, the cooling tube 1 includes a tube tube 11, the inside of the tube tube 11 is hollow, the top of the tube tube 11 communicates with the bottom end of the cooling tube 12, and the cooling tube 12 includes a bottom The end of the outer cylinder 123 is fixedly connected to the tube 11, the end of the outer cylinder 123 is fixedly connected to the inner cylinder 122, and the inner wall of the inner cylinder 122 is fixedly connected to the heat dissipation frame 4, and the left end of the heat dissipation frame 4 in the inner cylinder 122 is provided with a fan. The heat dissipation frame 4 includes a frame plate 41 fixedly connected to the inner cylinder 122. The fan-shaped fins 42 coaxial with the inner cylinder 122 are fixedly connected to the frame plate 41. There are several cooling cylinders 1, and several cooling cylinders 1 form a linear array and pass throu...

Embodiment 3

[0043] Such as Figure 1-5 As shown, an immersion cooling device for plastic pipe production includes a cooling tube 1, the cooling tube 1 includes a tube tube 11, the inside of the tube tube 11 is hollow, the top of the tube tube 11 communicates with the bottom end of the cooling tube 12, and the cooling tube 12 includes a bottom The end of the outer cylinder 123 is fixedly connected to the tube 11, the end of the outer cylinder 123 is fixedly connected to the inner cylinder 122, and the inner wall of the inner cylinder 122 is fixedly connected to the heat dissipation frame 4, and the left end of the heat dissipation frame 4 in the inner cylinder 122 is provided with a fan. The heat dissipation frame 4 includes a frame plate 41 fixedly connected to the inner cylinder 122. The fan-shaped fins 42 coaxial with the inner cylinder 122 are fixedly connected to the frame plate 41. There are several cooling cylinders 1, and several cooling cylinders 1 form a linear array and pass thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com