Bag sleeving, bag discharging and bag pulling assembly of water pipe bag sleeving machine

A technology of bagging machine and water pipe, which is applied in the direction of tubular objects, special packaging objects, packaging, etc., and can solve the problems of lack of bagging and bagging components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to easily understand the technical means, creation features, objectives and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

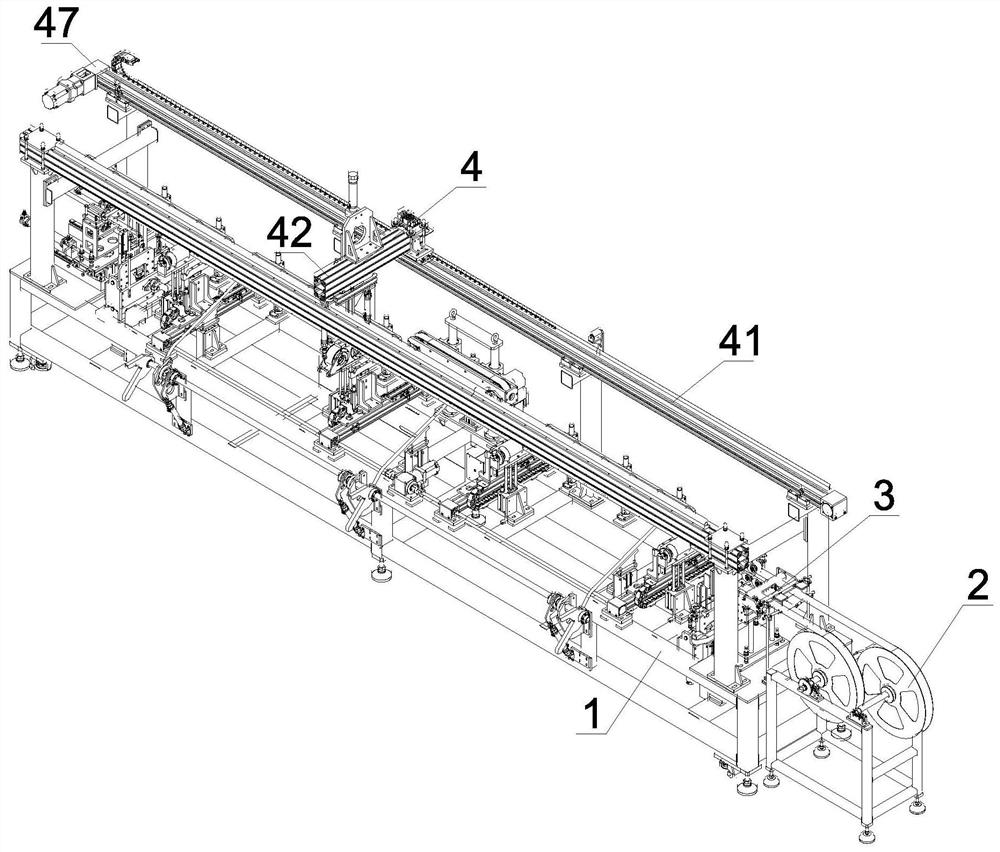

[0037] Such as Figure 1-Figure 14 As shown, a water pipe bagging machine bagging and bagging pull bag assembly, it consists of a bag hanging device 2 fixed on one end of the water pipe bagging machine frame 1, a bag discharging device 3, and the top of the water pipe bagging machine frame 1 The movable bag-drawing device 4 constitutes;

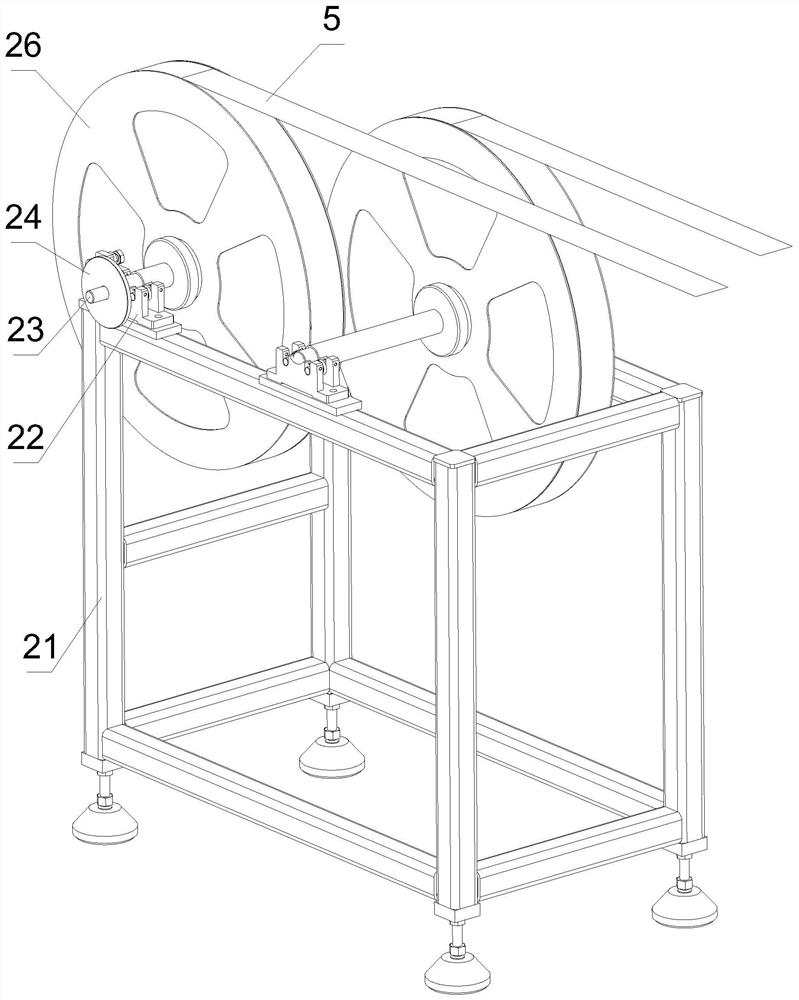

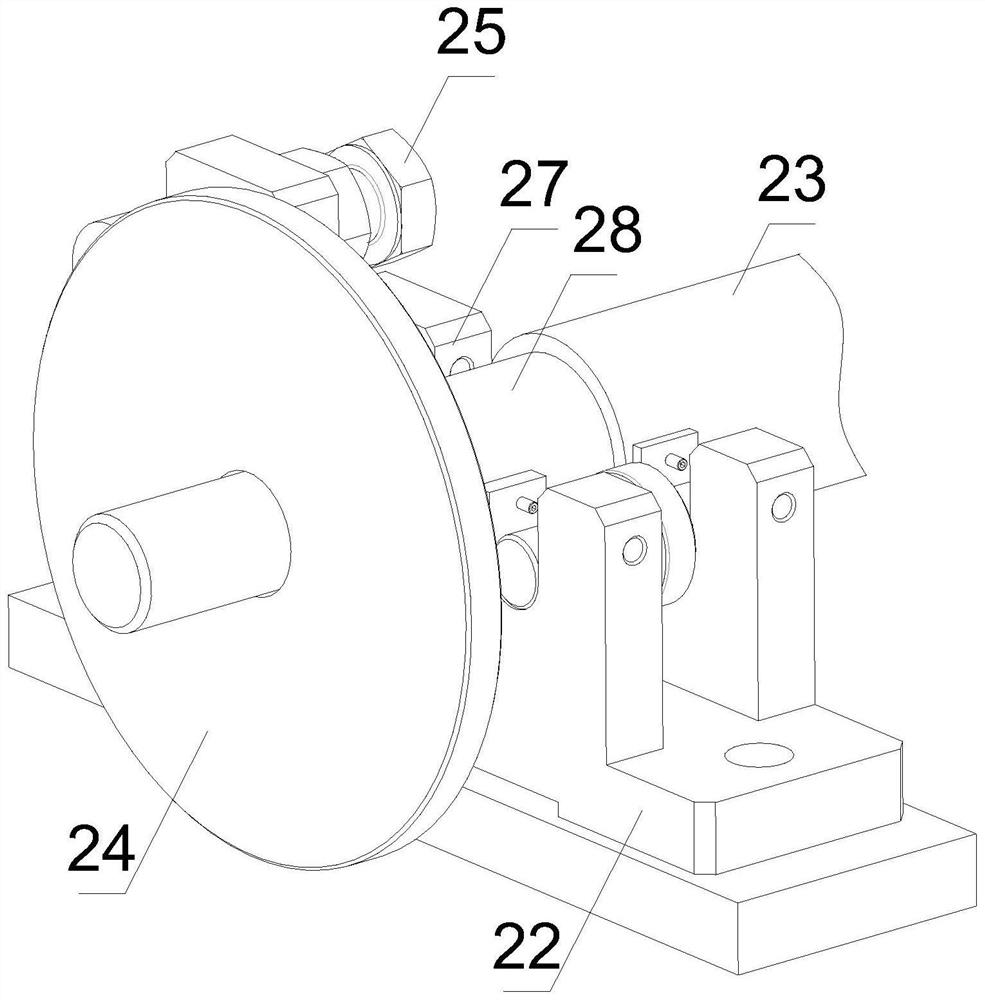

[0038] Such as figure 2 , image 3As shown, the bag hanging device 2 is composed of a bag hanging bracket 21, a rotating shaft support 22, a bag hanging rotating shaft 23, a friction wheel 24, a friction adjustment screw 25, a bag hanging fixed wheel 26, and the bag hanging bracket 21 is arranged on the water pipe bagging machine. At the outer end of the frame 1, at least a pair of rotating shaft supports 22 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com