A method for controlling the dimensional accuracy of cutting cotton felt

A technology for dimensional accuracy and cotton felt, which is applied in the field of controlling the dimensional accuracy of cutting cotton felt, can solve the problems of low production efficiency, easy pollution of the processing environment, health injury of operators, etc., achieves easy cleaning, realizes production process automation, and ensures green environmental protection. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

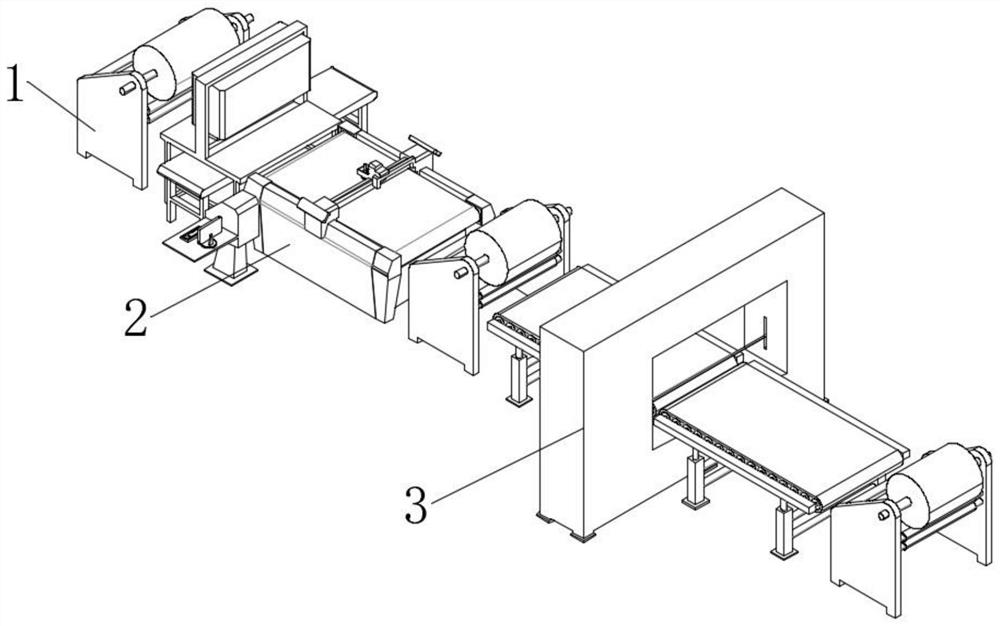

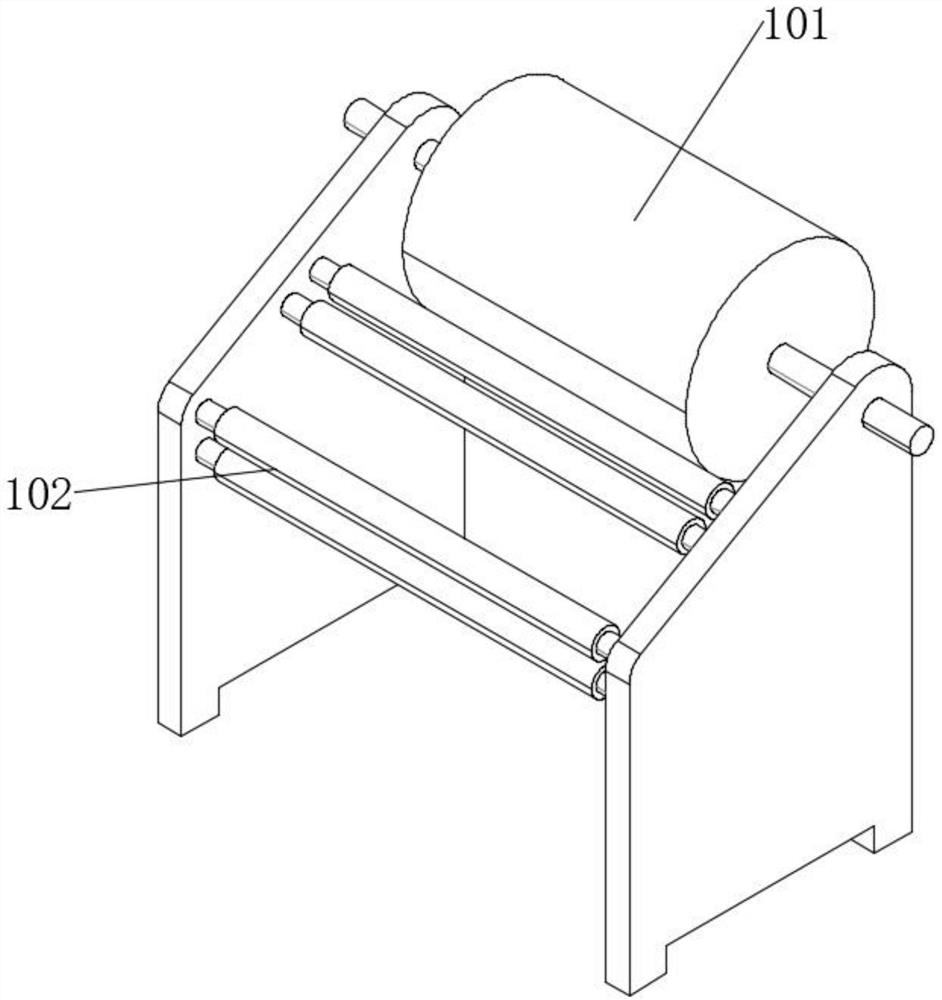

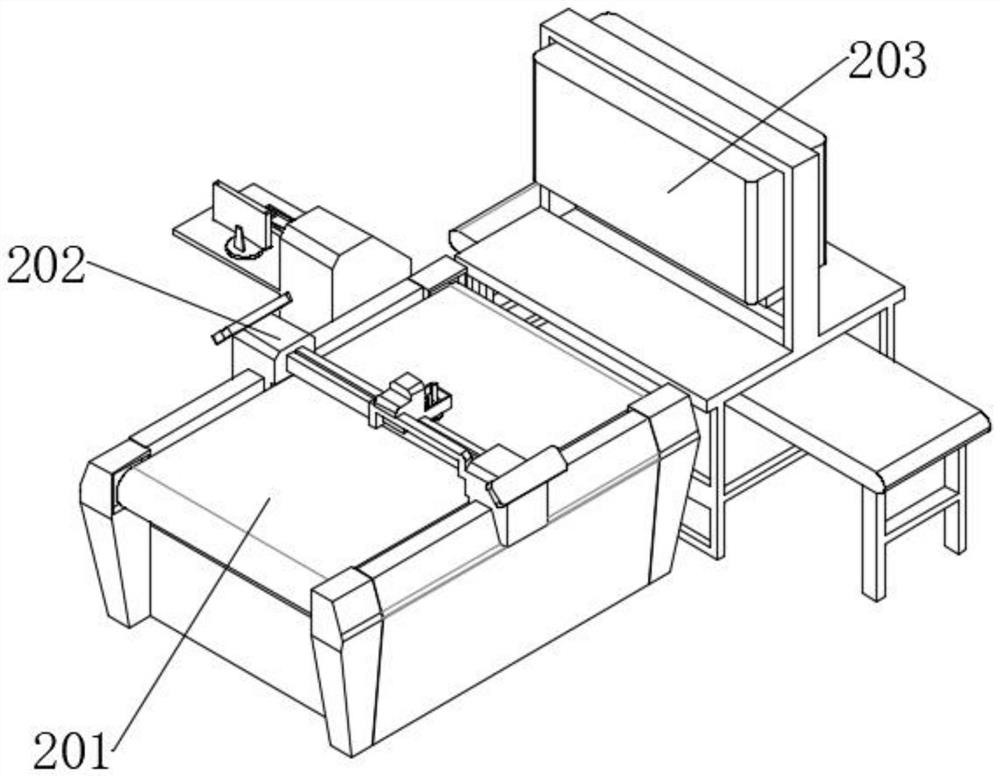

[0042] A method for controlling the dimensional accuracy of cutting cotton felt, the main steps of which include:

[0043] S1. Input data, input the corresponding data of cotton felt cutting into the processing terminal of the cotton felt cutting device according to its own cutting requirements. The most important data are the thickness and shape of the cut cotton felt. The thickness of the cotton felt can be directly input, while the cotton felt The shape of the felt needs to be input into pre-designed CAD or other engineering drawings;

[0044] S2, data call, the processing terminal calls the storage data of the Internet of Things cloud according to the data of the thickness and shape of the cotton batt entered in S1, the input data. Its storage data includes, but is not limited to, the tension degree and feeding speed of the cotton felt during cutting and other mechanical data related to cotton felt cutting production. The data stored in the IoT cloud cannot be recalled to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com