Production process of laminated kraft paper

A production process and technology of kraft paper, applied in the production process of coated kraft paper, can solve problems such as brittleness enhancement, kraft paper breakage, and affecting processing, and achieve the effects of increasing bonding strength, ensuring production quality, and ensuring molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

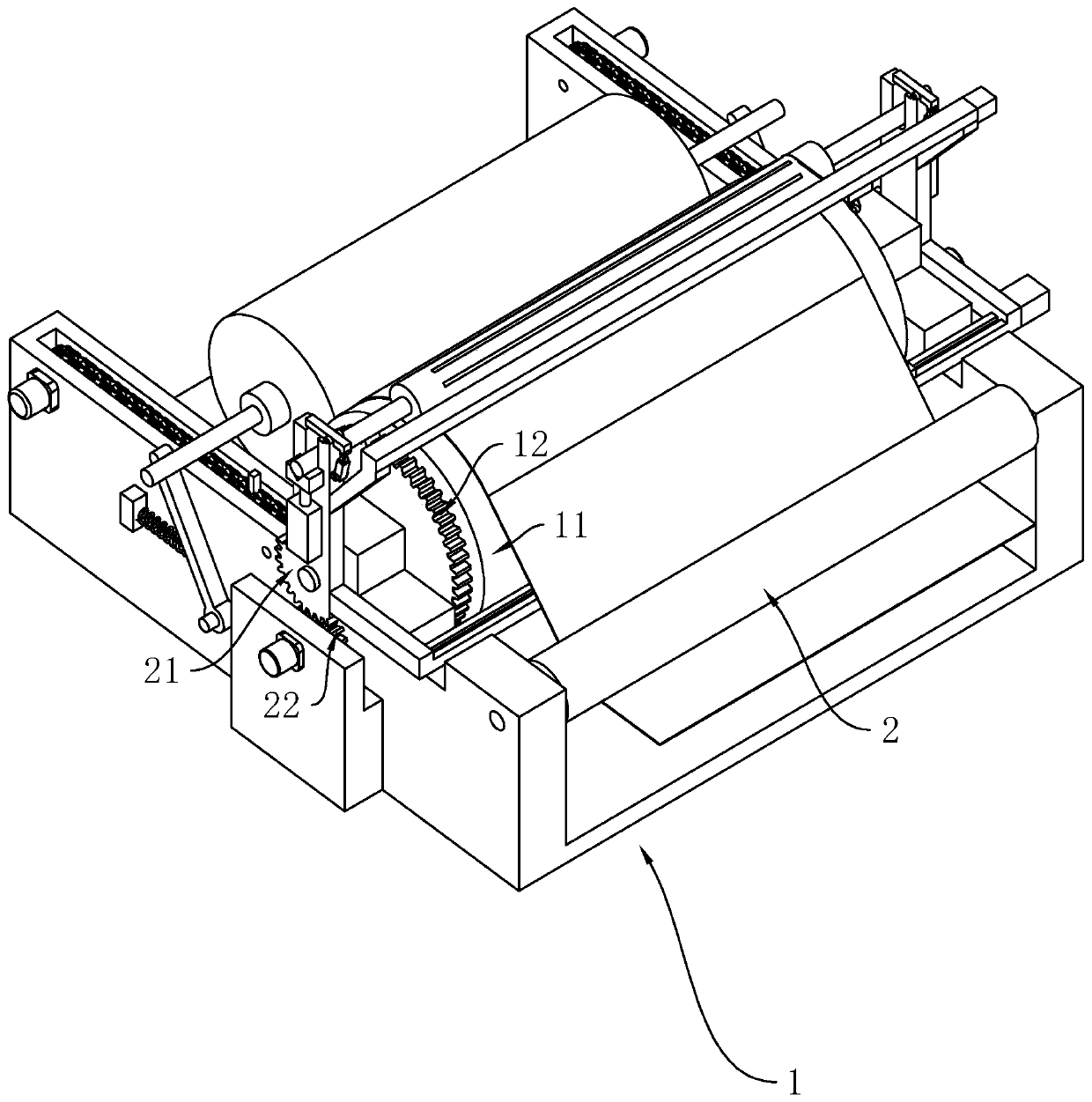

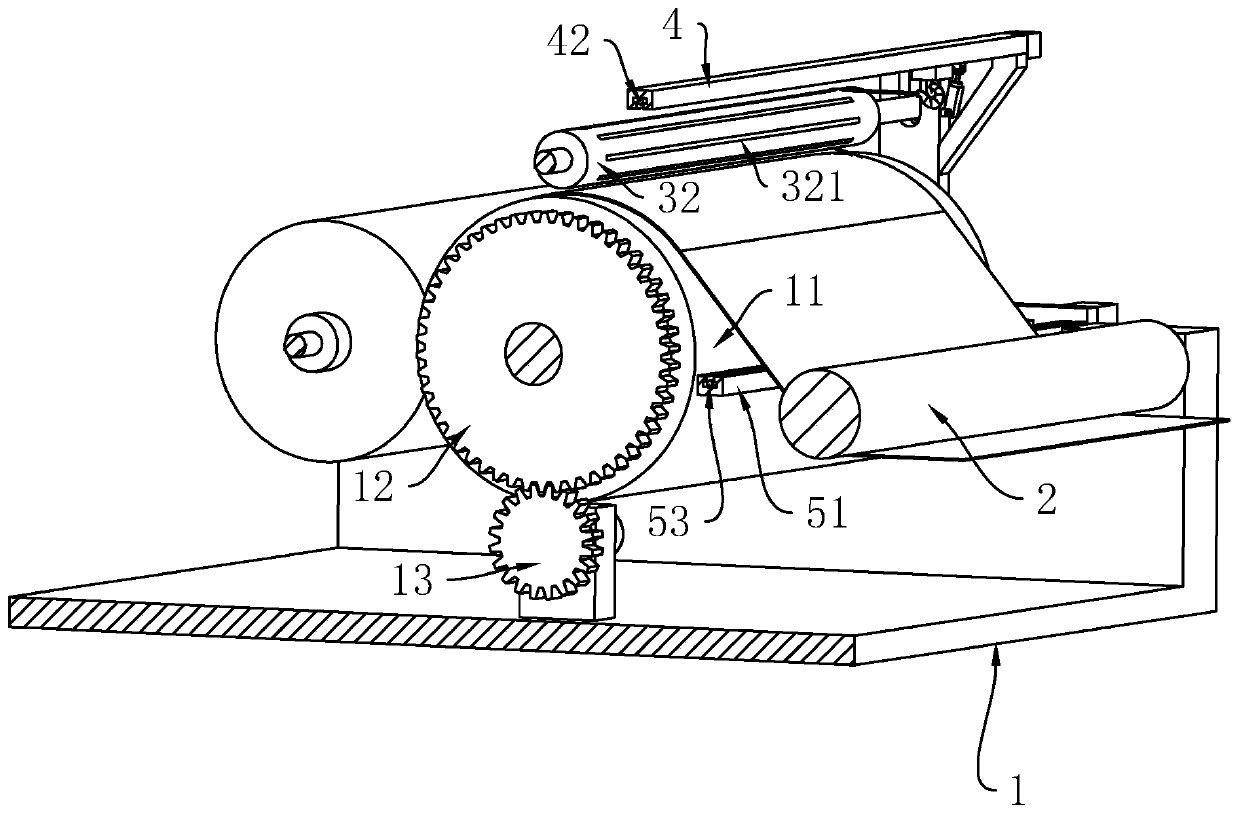

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

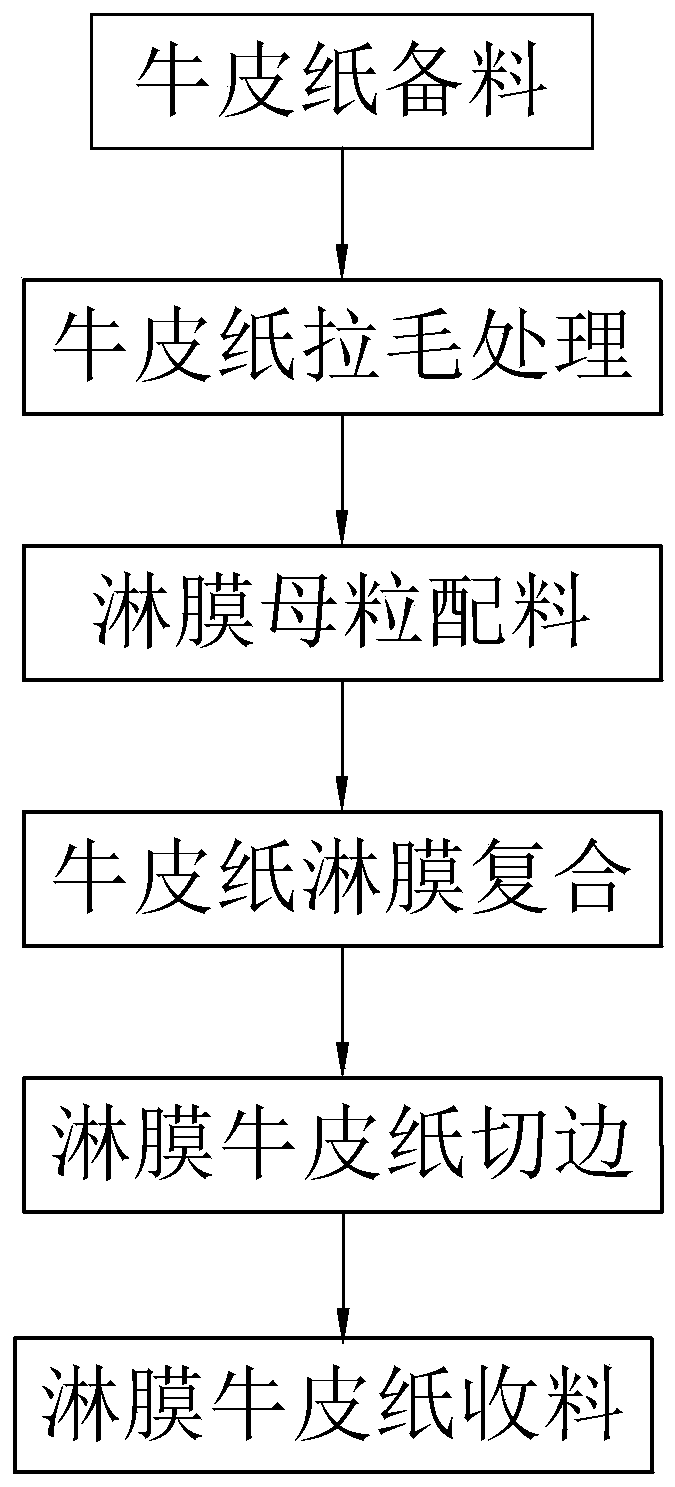

[0045] refer to figure 1 , is the production technology of a kind of coated kraft paper disclosed by the present invention, comprises the following steps

[0046] Step 1, kraft paper preparation,

[0047] 1. Base paper moisture detection, select kraft paper roll as kraft paper raw material, and install moisture detection device 1 on the output side of kraft paper roll, after sending out the paper of kraft paper roll, directly carry out moisture detection through moisture detection device 1 to obtain kraft paper moisture data;

[0048] 2. Base paper moisture adjustment, install high temperature water mist spraying device and high temperature drying device in sequence along the conveying direction of kraft paper on the side of the moisture detection device away from the kraft paper roll, and select to open the high temperature water mist spraying device accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com