Combined type partition light steel keel

A light steel keel and combined technology, applied to walls, building components, buildings, etc., can solve the problems of increased steel consumption and overall cost increase, and achieve the effect of reducing assembly man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following examples illustrate possible implementations of the present invention, but are not intended to limit the protection scope of the present invention.

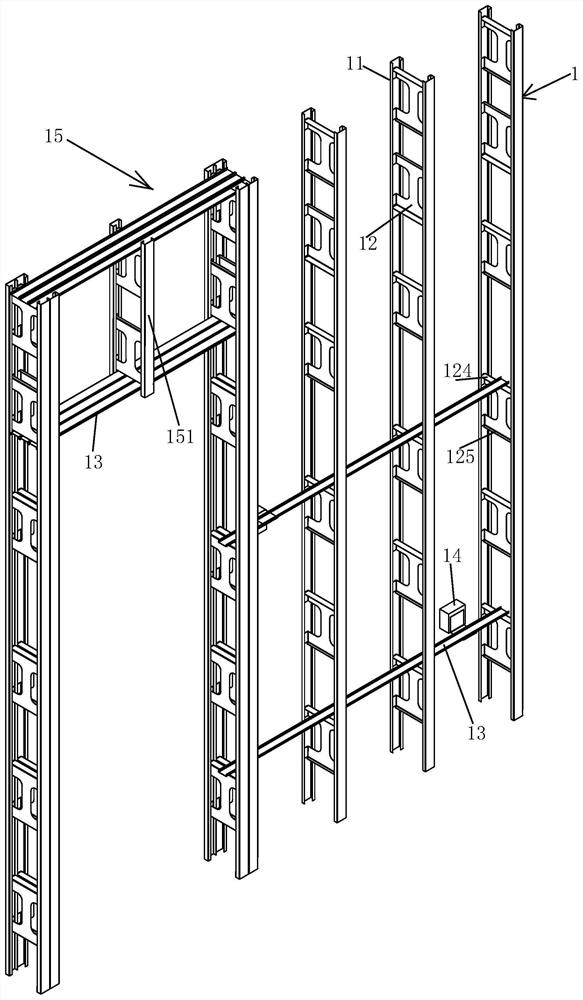

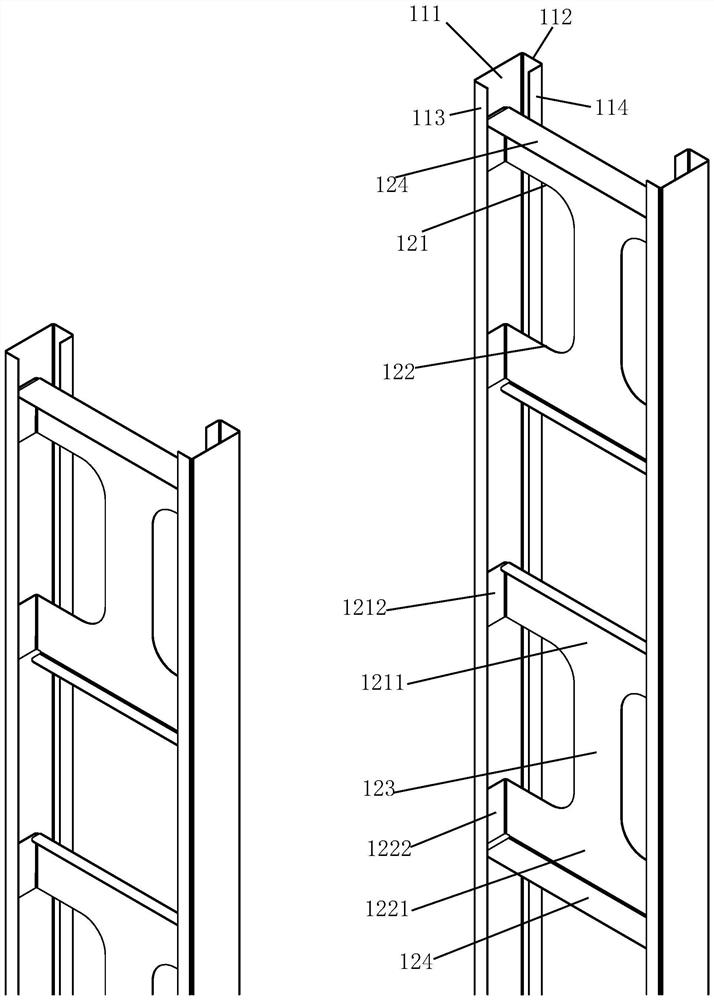

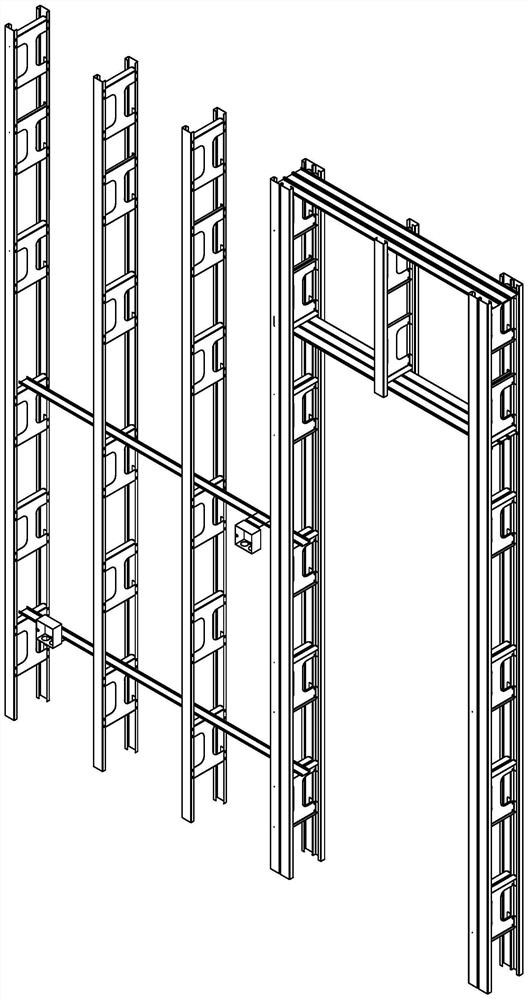

[0038] Such as figure 1 Shown is the first embodiment of the present invention, a combined partition wall light steel keel, including a number of vertical keel units 1 arranged at intervals, the vertical keel unit includes two vertical keels 11, and the grooves of the two vertical keel 11 The openings are opposite and arranged at intervals, and several vertically spaced connecting pieces 12 are connected between the two vertical keels 11, and vertical keel units of different thicknesses can be obtained through connecting pieces of different lengths. The vertical keel can be C-shaped or U-shaped or other structures, and in the present embodiment, the vertical keel is preferably the following structure: as Figure 6 As shown, the vertical keel 11 includes an L-shaped keel body, and the keel body includes a bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com