A method for adjusting a continuous zoom system

A technology of zoom system and adjustment method, which is applied in the directions of installation, instrumentation, optics, etc., can solve the problems of cumbersome method for determining the focal plane position of the zoom lens, low efficiency of zoom lens installation and adjustment, and imaging quality control, etc. Position and focal plane determination process, saving assembly time, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. Apparently, the described embodiments do not limit the present invention.

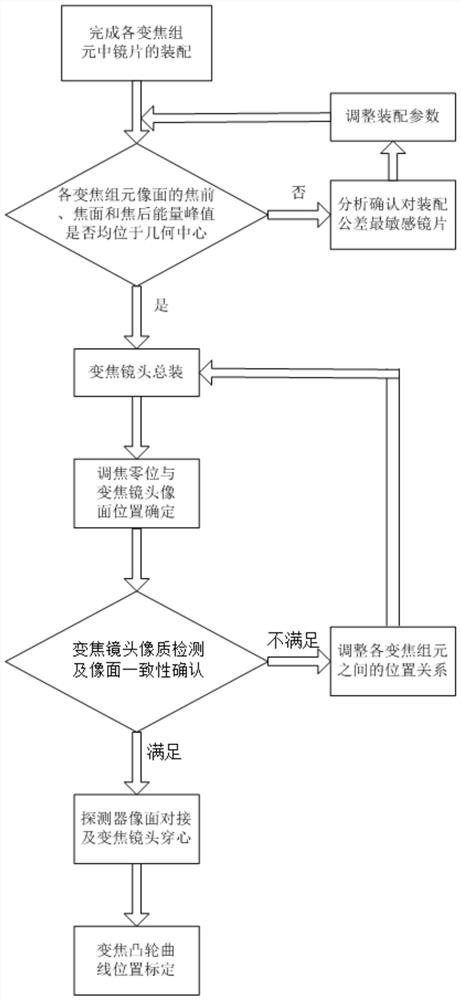

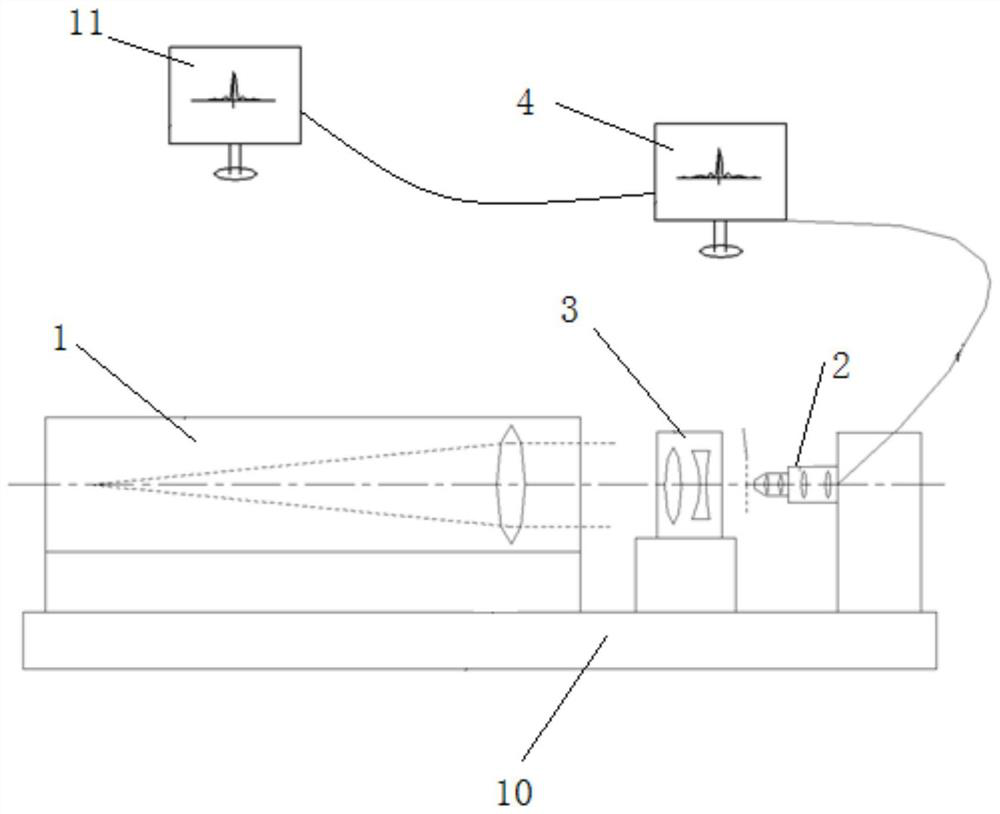

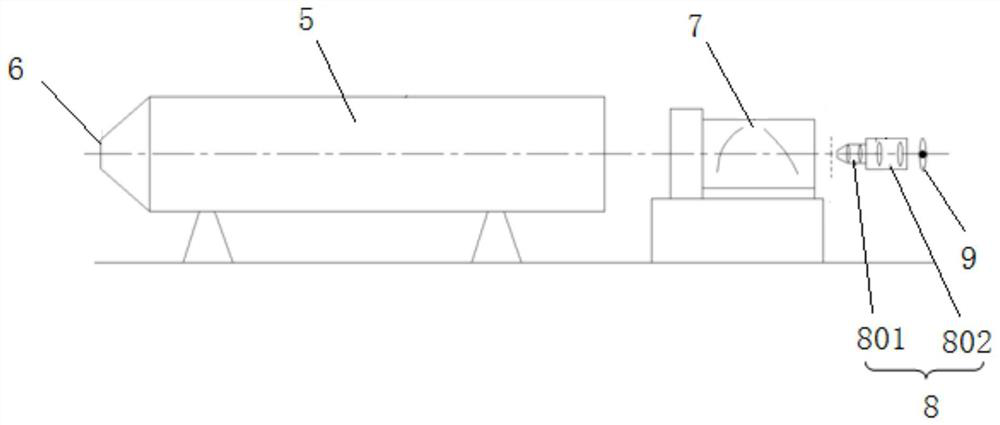

[0042] like figure 1 As shown, the present invention provides a method for assembling and adjusting a continuous zoom lens, which sequentially includes the framing and centering of the lenses in the zoom components, the assembly of the lenses in each zoom component of the zoom lens, including a fixed group and a moving group, each zoom Component imaging quality inspection and adjustment, zoom lens assembly, focus zero position and zoom lens image plane position determination, zoom lens image quality inspection, detector image plane docking and zoom lens penetration, zoom cam curve position calibration in total eight Each process is completed in sequence, and the next process is performed after meeting the requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com