Engine braking castellation mechanism

A technology for structural components and engines, applied in engine components, machines/engines, mechanical equipment, etc., to solve problems such as slowing down vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

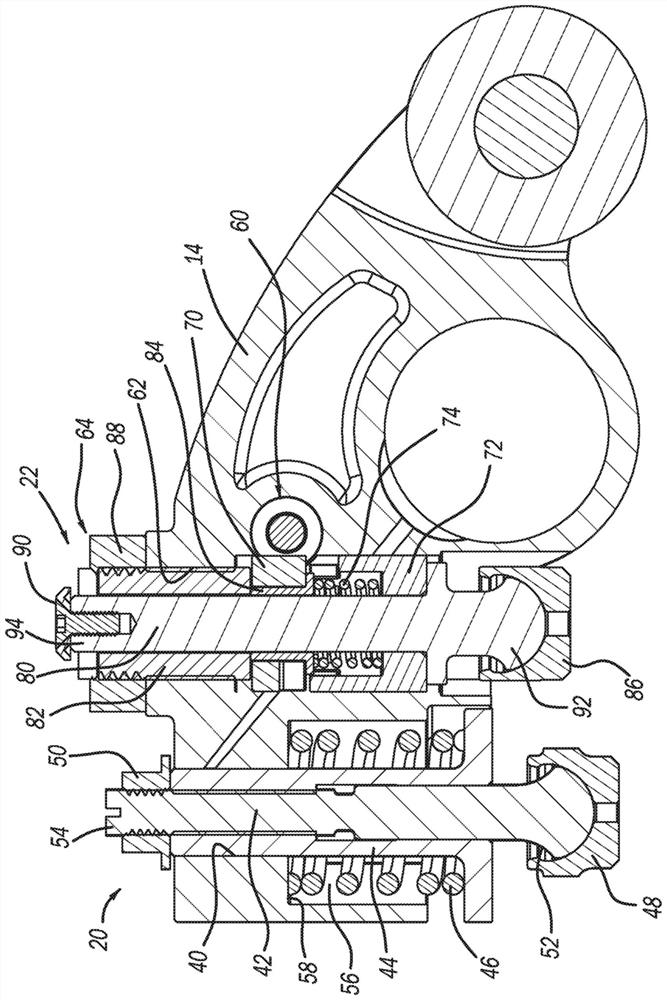

[0041] Especially at low engine speeds, heavy-duty (HD) diesel engines require high braking power. Some HD diesel engines are configured with valve trains with valve bridges, and include single overhead cam (SOHC) and overhead valve (OHV) valve trains. The present disclosure provides high braking power without imposing high loads on the rest of the valve train, especially the pushrods and camshafts. In this regard, the present disclosure provides a configuration in which only one exhaust valve is opened during a braking event.

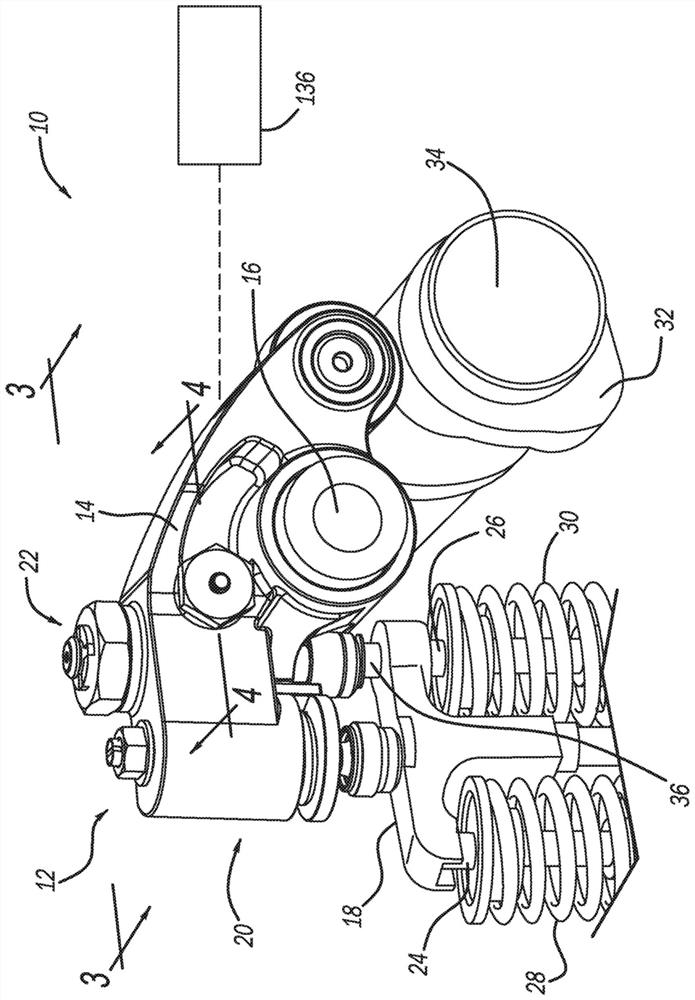

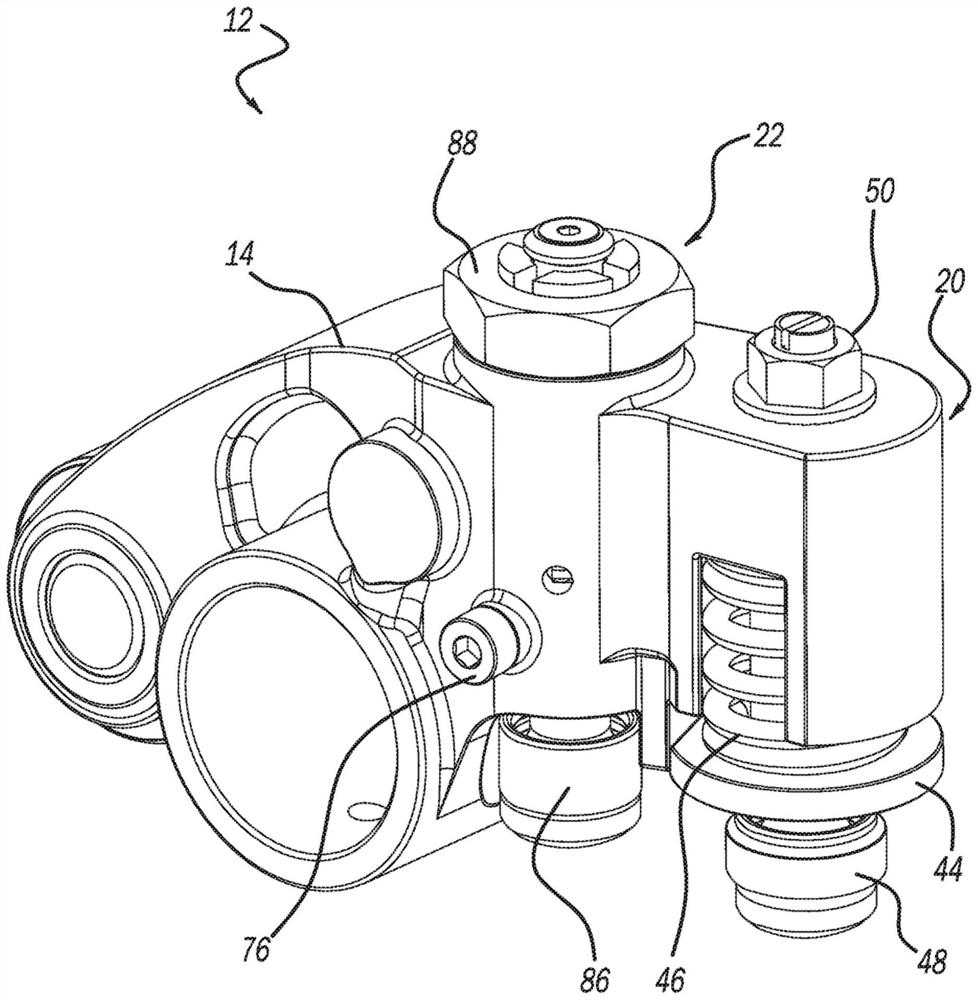

[0042] first reference figure 1 , shows a partial valve train assembly constructed in accordance with one example of the present disclosure and is generally identified as element numeral 10 . The partial valve train assembly 10 utilizes engine braking and is shown configured for use in a six cylinder engine. It should be understood, however, that the present teachings are not so limited. In this regard, the present disclosure may be used in any val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com