Horizontal self-overturning efficient sedimentation tank

A high-efficiency sedimentation tank and self-turning technology, applied in the field of sedimentation tanks, can solve the problems of clogging inclined tube packing and increasing sedimentation efficiency, and achieve the effects of reducing operating costs, increasing sedimentation efficiency, and simplifying facility operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

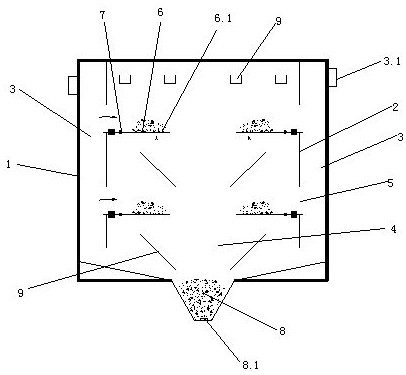

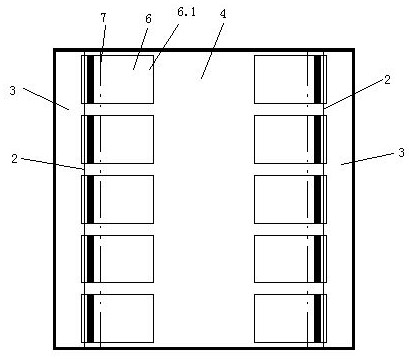

[0020] Example 1: as figure 1 As shown, a kind of horizontal self-flipping high-efficiency sedimentation tank comprises a tank body 1, and a number of partitions 2 are arranged in the tank body 1 to separate the tank body 1 into several water inlet areas 3 and several sedimentation areas 4 from left to right, and the tank body 1 1. It includes two water inlet areas 3 and one sedimentation area 4. The water inlet area 3 is located on both sides of the sedimentation area 4. The water inlet area 3 is provided with a water inlet 3.1. 9. There are several water distribution ports 5 on the partition 2, and several water distribution ports are arranged on the partition 2 from top to bottom. Each row of water distribution ports is arranged at equal intervals, and each row of water distribution ports is provided with several water distribution ports 5. The distance between two adjacent water distribution ports 5 in the mouth is equal. Each sedimentation zone 4 is provided with a numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com